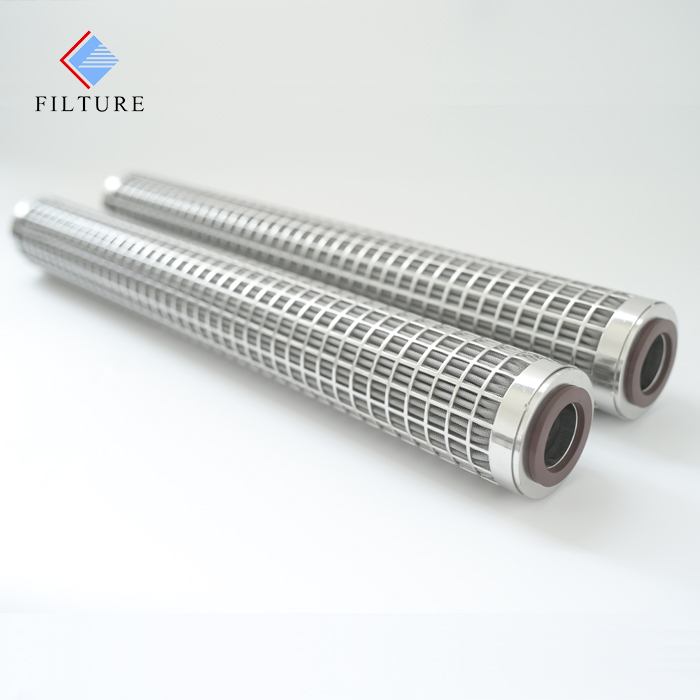

Stainless Steel Cartridge Filter Element

Absolute Rate

Cleanable

Standard Sizes:

Outer Diameter: 60mm(2.36")

Length: 254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: Above 1um

- Product Description

Stainless Steel Cartridge Filter Element: High-Performance Filtration for Demanding Industries

Welcome to our premium stainless steel cartridge filter elements—designed to offer efficient, durable, and reliable filtration solutions for a wide range of industrial applications. Whether you're in the chemical, petrochemical, aerospace, medical, or energy sector, our stainless steel filter elements provide the precision and performance you need. Built to withstand high pressures, extreme temperatures, and corrosive environments, these filters ensure top-tier performance in your most demanding filtration needs.

Technical Specifications

Our products are engineered with superior materials and quality control to ensure peak performance. Here are the key technical specifications:

| Parameter | Description |

|---|---|

| Material | Stainless Steel, Titanium, Nickel (custom options) |

| Pore Size Range | 1 µm to 100 µm |

| Filtration Efficiency | ≥ 99.9% (depending on pore size) |

| Operating Temperature | Up to 800°C (depending on material and configuration) |

| Operating Pressure | Up to 40 bar (varies by design and application) |

| Length | Custom lengths available (standard: 10", 20", 30") |

| Outer Diameter | 2.5" to 4.5" (custom sizes available) |

Key Features

- Tall Porosity: Guarantees ideal liquid stream whereas keeping up amazing filtration performance.

- Corrosion and High-Temperature Resistance: Made from stainless steel and other high-quality metals, these channel components are built to handle extraordinary conditions, making them perfect for requesting mechanical applications.

- Durability and Reusability: Our channels are simple to clean and reusable, lessening upkeep costs and guaranteeing long-lasting performance.

- Precision Filtration: With pore sizes extending from 1 µm to 100 µm, these channel components give a tall level of filtration accuracy, assembly strict industry measures.

Applications

Stainless steel cartridge filter elements are perfect for a variety of industries where filtration is critical. Some of the key applications include:

- Petrochemical and Oil & Gas: Utilized in filtration frameworks for oil and gas preparing to guarantee virtue and anticipate contamination.

- Pharmaceutical and Biotechnology: Connected in filtration of gasses and fluids in delicate pharmaceutical and restorative applications.

- Food and Refreshment: Guaranteeing the most noteworthy guidelines of cleanliness and quality in nourishment and refreshment generation through fine filtration processes.

- Gas Filtration: Successful in isolating gasses and particulate matter in mechanical forms such as discuss partition and purification.

- Aerospace: Aviation applications require profoundly tough and lightweight channel components, and stainless steel channels are perfect for these requesting situations.

Manufacturing Process

Our stainless steel cartridge channels are created utilizing progressed sintering and shaping advances, guaranteeing that each component has the required quality, soundness, and consistency. By applying multi-layer structures and extraordinary molding methods, we upgrade their auxiliary keenness, making them reasonable for the harshest working conditions.

Customization Options

We understand that every industry has unique needs, which is why we offer a full range of customization options for the products. You can customize the following aspects:

- Estimate: We offer channels in different sizes, counting lengths and breadths, to fit your particular filtration systems.

- Pore Estimate: Select from a wide run of pore sizes to meet the particular filtration necessities of your process.

- Material: Select from stainless steel, titanium, or nickel for the culminate fabric for your working environment.

Quality Assurance

We take quality very seriously. Each product undergoes rigorous testing and inspection to ensure that it meets the highest standards of durability, efficiency, and performance. Our products are certified to international standards such as ISO, CE, and FDA, ensuring they meet global procurement requirements.

Packaging and Logistics

Our filter elements are carefully packaged to prevent any damage during shipping. We ensure fast and reliable delivery to your location, whether you are based domestically or internationally. Our logistics team will work closely with you to meet your delivery schedules and ensure that your products arrive on time and in perfect condition.

Customer Support

We believe in providing ongoing support for our customers. Our dedicated team is available before and after your purchase to offer technical assistance, troubleshooting, and guidance on product maintenance. You can reach us at sam.young@sintered-metal.com or Tel/Whatsapp: +8615877694221 for prompt assistance.

Why Choose Us?

- Experience: We have years of experience in manufacturing high-quality stainless steel cartridge filters for a variety of industries.

- Customization: Our flexible production capabilities ensure that we can meet your unique filtration requirements.

- Quality: Our products are designed to offer superior durability and efficiency, making them a long-term investment for your operations.

- Timely Delivery: We are committed to on-time delivery, ensuring minimal downtime for your operations.

- Global Reach: With a strong international presence, we serve clients across Europe, North America, Asia-Pacific, and the Middle East.

OEM Services

We offer OEM services to manufacture filters according to your specific requirements, including custom designs, materials, sizes, and filtration capacities. No matter how unique your needs may be, we can deliver the perfect solution for you.

Frequently Asked Questions (FAQs)

What is the maximum operating temperature of the product?

- Our stainless steel cartridge filter elements can handle operating temperatures up to 800°C, depending on the material.

Can I get a custom size or pore size?

- Yes, we offer full customization for size, pore size, and material to meet your specific filtration needs.

What industries can benefit from using stainless steel cartridge filters?

- Industries such as petrochemical, pharmaceutical, aerospace, food and beverage, and more rely on stainless steel cartridge filters for their filtration needs.

Contact Details

For inquiries or more information, please don't hesitate to reach out to us:

- Email: sam.young@sintered-metal.com

- Tel/Whatsapp: +8615877694221

Our team is ready to provide you with tailored solutions and expert advice to help you make the best filtration choice for your industry.

_1742364652633.webp)