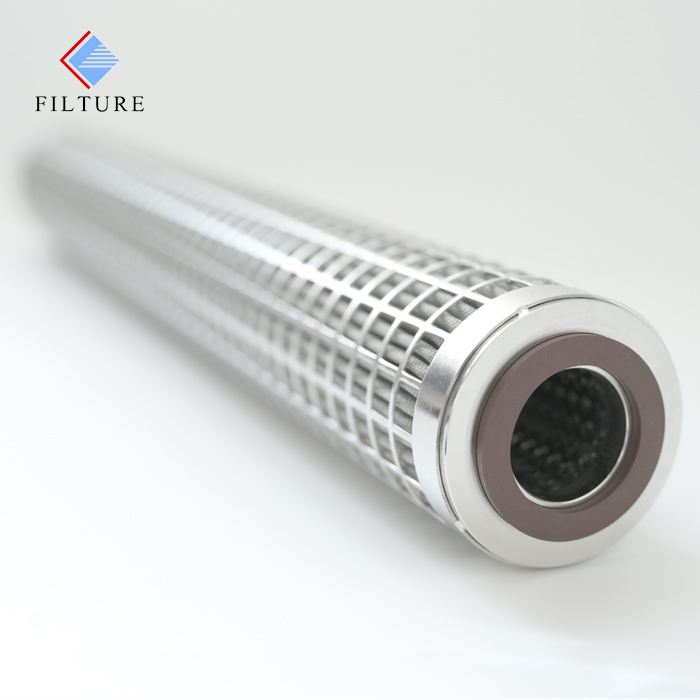

Eco-Mesh Series Stainless Steel Cartridge Filters

Absolute Rate

Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length: 254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: Above 1um

- Product Description

Stainless Steel Pleated Filter Elements: High-Performance Filtration Solutions for Demanding Industries

Welcome to our product page for Eco-Mesh Series Stainless Steel Cartridge Filters, designed to meet the filtration needs of industries that require high efficiency, durability, and precision. Whether you're in the petrochemical, pharmaceutical, aerospace, or energy sector, our pleated filter elements are engineered to provide exceptional performance in the most challenging environments.

Product Introduction

Our products are crafted for superior filtration performance, making them ideal for industrial applications that involve extreme conditions. These filter elements are known for their high-temperature resistance, corrosion resistance, and structural stability. They offer exceptional durability and reliability, ensuring long-lasting performance even in high-pressure and high-temperature settings. Perfect for high-temperature and high-pressure applications, these filters excel in environments where other materials may fail, providing consistent filtration performance over extended periods.

Technical Specifications

The table below provides key technical specifications for our products, ensuring that you can make an informed decision when selecting the right filter for your needs.

| Parameter | Specification |

|---|---|

| Material | Stainless Steel (304, 316, 316L, or custom) |

| Pore Size Range | 1µm to 1000µm |

| Filtration Efficiency | 99.9% |

| Operating Temperature | -200°C to 600°C |

| Operating Pressure | Up to 150 bar |

| Length | Customizable, typically 100mm to 1000mm |

| Diameter | Customizable, typically 10mm to 250mm |

| Flow Capacity | High flow rates depending on size and pore structure |

| Certification | ISO, CE, FDA (when applicable) |

Product Features (Key Features)

Tall Porosity and Efficiency

Our items highlight a tall porosity structure, which permits them to channel out pollutions successfully without limiting stream rates. This makes them idealize for businesses where fine filtration and tall throughput are essential.

Durability and Longevity

Built to withstand unforgiving situations, these channel components are strong and safe to erosion, tall temperatures, and mechanical stretch. With negligible upkeep required, they diminish downtime and lower by and large working costs.

Easy to Clean and Reuse

One of the standout highlights of our items is their simple cleaning and reusability. Not at all like other sorts of channels, these components can be cleaned and reused numerous times, giving great cost-efficiency in the long run.

Applications

Our stainless steel pleated filter elements are used across a variety of industries, offering optimal filtration and separation capabilities. Some common applications include:

- Petrochemical Industry: Utilized for oil and gas filtration, expelling particles from powers, chemicals, and lubricants.

- Pharmaceutical Industry: Guaranteeing sterile conditions in the generation of solutions and antibodies, and sifting debasements in sedate fabricating processes.

- Food & Refreshment: Filtration of oils, refreshments, and other nourishment items to guarantee virtue and quality.

- Gas Filtration: Reasonable for discuss and gas filtration frameworks in assorted mechanical processes.

- Aerospace: Giving filtration arrangements for airplane and aviation fabricating, where tall quality and lightweight properties are fundamental.

Manufacturing Process

The sintered metal channel fabricating handle includes intertwining metal powder beneath tall weight and temperature, making a tough, solid, and steady channel structure. This handle guarantees a tall degree of consistency and reliable pore estimate, making our creased channels exceedingly dependable in requesting conditions. We too offer multi-layer structures for expanded filtration productivity, permitting for numerous filtration stages in a single channel.

Customization Options

We understand that every industrial application has its own specific needs. That’s why we offer customized products tailored to your exact specifications. From varying pore sizes to custom shapes, materials, and sizes, our flexible production capabilities ensure that you get the perfect filter for your operation.

Quality Assurance

At [Shaanxi Filture New Material Co., Ltd.], quality is our top priority. We adhere to strict quality control processes throughout the production of our products. Our filters undergo rigorous testing and inspections to ensure they meet global standards such as ISO, CE, and FDA certifications.

Packaging and Logistics

To ensure that our products reach you safely and on time, we use secure packaging methods designed to prevent damage during transit. We also provide detailed logistics information, including delivery time estimates, so you can plan your operations effectively.

Customer Support

We are committed to providing excellent customer service both before and after your purchase. Our team of experts is always available to assist with product selection, installation guidance, and troubleshooting. You can reach us at sam.young@sintered-metal.com or via Whatsapp at 8615877694221.

Why Choose Us?

- Industry Expertise: With years of experience in the filtration industry, we understand the specific needs of various sectors.

- Customization: We offer flexible production capabilities to create tailored solutions for your unique needs.

- Quality and Reliability: Our filters undergo thorough testing to ensure high performance in challenging environments.

- On-Time Delivery: We pride ourselves on our efficient logistics network, ensuring your products arrive when you need them.

OEM Services

We also provide OEM services, offering custom manufacturing solutions tailored to your specifications. Whether it’s a special material, unique size, or a custom design, we can produce filter elements that perfectly meet your needs.

Frequently Asked Questions (FAQs)

1. What are the products used for?

Our filters are used for fine filtration, separation, and purification in industries such as oil and gas, pharmaceuticals, aerospace, and food processing.

2. Can I customize the filter elements?

Yes, we offer custom options in terms of size, material, pore size, and shape to meet the specific needs of your application.

3. What certifications do your filters hold?

Our filters comply with international certifications such as ISO, CE, and FDA, ensuring that they meet global quality standards.

4. How do I clean and maintain the filters?

Our stainless steel pleated filter elements are designed to be easily cleaned and reused. You can follow the cleaning instructions provided with each order for long-term use.

Contact Details

For inquiries, product customization, or technical support, feel free to reach out:

- Email: sam.young@sintered-metal.com

- Tel/Whatsapp: +8615877694221

We look forward to helping you find the perfect filtration solution for your needs!

_1742364652633.webp)