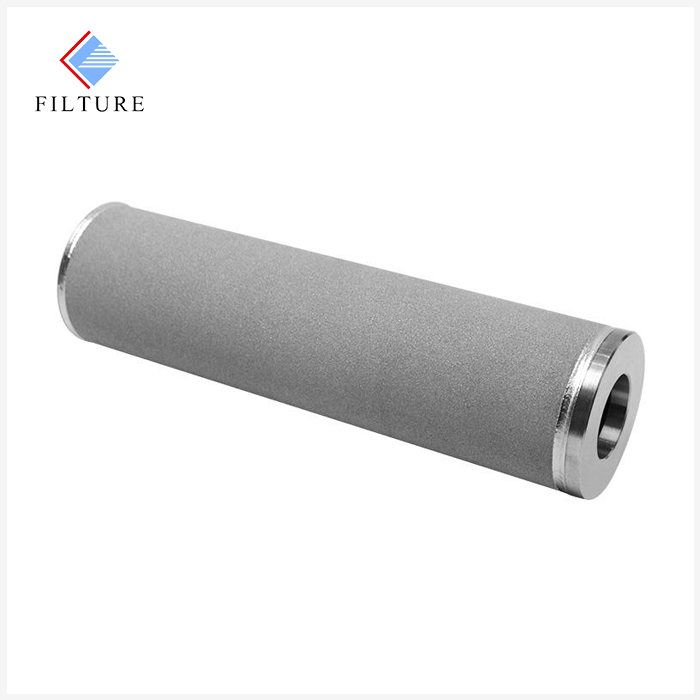

Sintered Metal Powder Filter Cartridge

Absolute Rate :Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length:

254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: 0.22-100um

- Product Description

High-Efficiency Filtration Solutions

Our sintered metal powder filter cartridges are designed to deliver high-efficiency filtration in extreme conditions. Built from high-performance materials such as stainless steel, titanium, and nickel, these cartridges exhibit exceptional resistance to high temperatures, corrosion, and pressure. Whether you operate in the energy, chemical, or medical industries, our filter cartridges provide a reliable solution for demanding applications.

Technical Specifications of Sintered Metal Powder Filter Cartridge

| Parameter | Details |

|---|---|

| Material | Stainless Steel 316L, Titanium, Nickel, Monel |

| Pore Size Range | 0.22 – 100 μm |

| Filtration Efficiency | Up to 99.9% for particles as small as 0.5 μm |

| Operating Temperature | -200°C to 800°C |

| Maximum Operating Pressure | Up to 30 MPa (4350 PSI) |

| Porosity | 30% – 50% |

| Dimensions | Customizable (length, diameter, wall thickness) |

| Standards | ISO 9001:2015, CE, FDA |

Key Features of Our Sintered Metal Powder Filter Cartridge

High Porosity & Efficiency: Provides excellent permeability while ensuring superior filtration performance.

Durability & Reusability: With high mechanical strength and corrosion resistance, our cartridges offer long-lasting performance and can be easily cleaned for repeated use.

Wide Operating Range: Suitable for extreme environments, including high temperatures, high pressures, and corrosive media.

Customizable Design: Available in various shapes, sizes, and materials to meet specific customer requirements.

Applications of Sintered Metal Powder Filter Cartridge

They are used across a wide range of industries:

Energy Sector: Ideal for filtration in oil, gas, and power generation equipment.

Chemical Industry: Used in catalytic reactions, gas separation, and fine chemical processes.

Pharmaceutical & Medical: Ensures sterile filtration for medical devices and life science applications.

Food & Beverage: Provides safe and effective filtration in food processing and beverage production.

Aerospace: Lightweight, high-strength filters suitable for demanding aerospace applications.

Manufacturing Process

Our products are manufactured through a precise sintering process that involves compacting metal powders into a specific shape and heating them below their melting point. This process results in a porous yet robust structure that offers high strength, stability, and uniform pore distribution.

Key advantages of our manufacturing process include:

Multi-layer sintered structures for enhanced filtration.

Advanced molding techniques for complex geometries.

Customization Options

We understand that different industries have unique filtration needs. That’s why we offer fully customizable products:

Materials: Stainless steel, titanium, nickel, Monel, etc.

Pore Sizes: From ultra-fine filtration to coarse filtration.

Shapes & Sizes: Custom dimensions to fit specific equipment.

End Connections: Threaded, flanged, welded, or as required.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., we adhere to strict quality control protocols to ensure consistent product excellence. All our products undergo rigorous testing and inspection, including:

Material Analysis

Dimensional Checks

Performance Testing

We are proud to hold certifications such as ISO 9001:2015 and CE, ensuring our products meet global quality standards.

Packaging and Logistics

To guarantee safe delivery, our products are carefully packaged using high-quality materials that protect them from damage during transportation. We offer flexible logistics solutions to ensure timely delivery, whether you are located domestically or internationally.

Customer Support

Our commitment to customer satisfaction extends beyond product delivery. We offer comprehensive pre-sales and after-sales support, including:

Technical Consultation: Assisting with product selection and application.

After-Sales Service: Providing maintenance guidance and troubleshooting.

Contact Us: Email us at sam.young@sintered-metal.com or call/WhatsApp us at +8615877694221.

Why Choose Shaanxi Filture New Material Co., Ltd.?

Rich Industry Experience: With years of expertise in sintered metal filtration, we have a proven track record of delivering high-quality solutions.

Advanced R&D Capabilities: Our strong research and development team ensures continuous product innovation.

Reliable Supply Chain: We maintain a stable supply chain to ensure consistent and timely delivery.

Global Sales Network: Serving customers worldwide with efficient and professional service.

OEM Services

We offer OEM services for clients who require custom branding or specific product modifications. Whether you need a unique design or private labeling, our team is ready to meet your requirements.

Frequently Asked Questions (FAQs)

Q1: What materials are available for your products?

A1: We offer a range of materials, including stainless steel, titanium, nickel, and Monel.

Q2: Can I request custom pore sizes?

A2: Yes, we can customize the pore size according to your filtration requirements.

Q3: How do I clean and maintain the filter cartridges?

A3: Our filter cartridges can be cleaned using backflushing or ultrasonic cleaning methods.

Q4: Do you provide technical support?

A4: Yes, we offer comprehensive technical support, including installation guidance and troubleshooting.

Contact Us

For inquiries or further information, please contact us:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: +8615877694221

Let Shaanxi Filture New Material Co., Ltd. be your trusted partner for high-performance sintered metal powder filter cartridges. Contact us today and experience the difference in quality and service!

_1742364652633.webp)