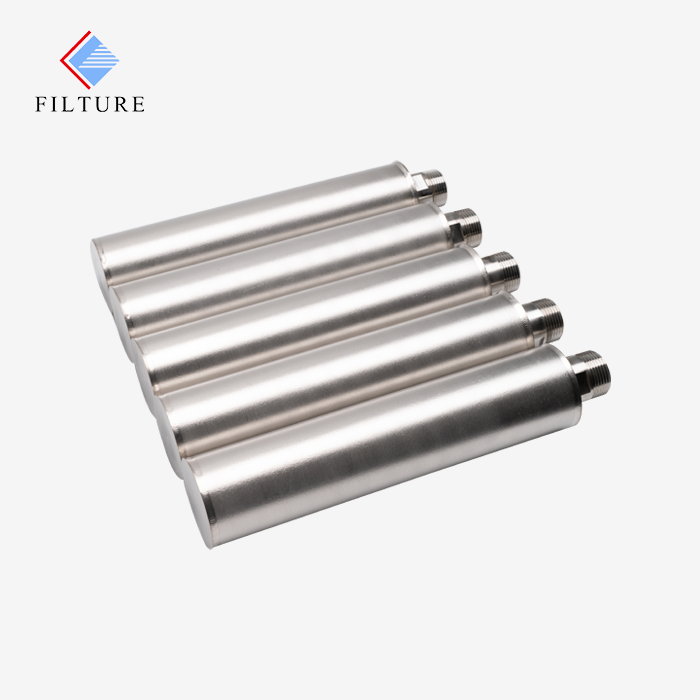

Stainless Steel Sintering Filter Element

Absolute Rate :Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length:

254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: 0.22-100um

- Product Description

Stainless Steel Sintering: The Ultimate Solution for High-Performance Filtration

The Stainless Steel Sintering Filter Element is widely recognized as an ideal solution for industrial filtration, delivering excellent durability, resistance to high temperatures, and superior filtration efficiency. Shaanxi Filture New Material Co., Ltd. provides advanced sintered metal filters designed to perform reliably under extreme conditions such as elevated temperatures, high pressures, and corrosive environments. Our products are engineered to meet the needs of industries from aerospace to medical devices, ensuring consistent performance and long-term reliability in critical applications.

Technical Specifications of Stainless Steel Sintered Filters

Our products are designed to meet the most stringent requirements. Here are the key technical details:

| Specification | Details |

|---|---|

| Materials | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.5 μm to 1000 μm |

| Filtration Efficiency | ≥ 99% for particles ≥ 1 μm |

| Operating Temperature | -200°C to 600°C |

| Operating Pressure | Up to 50 bar |

| Shape Options | Disc, Plate, Cylinder, Custom Shapes |

These specifications ensure our filters perform in a variety of challenging environments, from gas filtration in chemical plants to high-temperature applications in power generation.

|  |  |  |

|  |  |  |

Key Features of Stainless Steel Sintering Filter Element

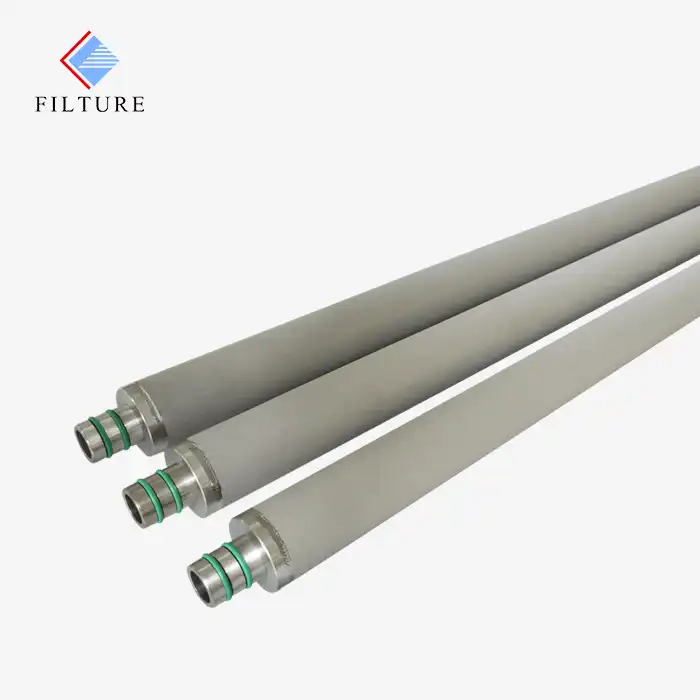

High Porosity: The sintering process creates a highly porous structure, allowing excellent flow rates and precise filtration performance.

Durability and Reusability: Designed for long service life, the filter element withstands harsh environments, requires minimal maintenance, and can be easily cleaned and reused.

Corrosion and Temperature Resistance: Engineered to resist corrosion and operate under elevated temperatures, making it suitable for demanding sectors such as petrochemical, aerospace, and pharmaceuticals.

Structural Stability: The sintering process ensures the filter element maintains integrity and consistent performance, even in high-pressure applications.

Applications of Stainless Steel Sintering Filter Element

These advanced filter elements play a vital role across multiple industries:

Petrochemical Industry: Applied in oil and gas systems for efficient separation and purification of fluids.

Pharmaceutical and Medical Devices: Certified for use in medical-grade equipment, providing safety and reliability in critical environments.

Food and Beverage Industry: Used in food processing and beverage filtration to preserve purity and meet strict quality standards.

Gas Filtration: Essential in chemical and energy sectors for reliable gas separation, even under extreme working conditions.

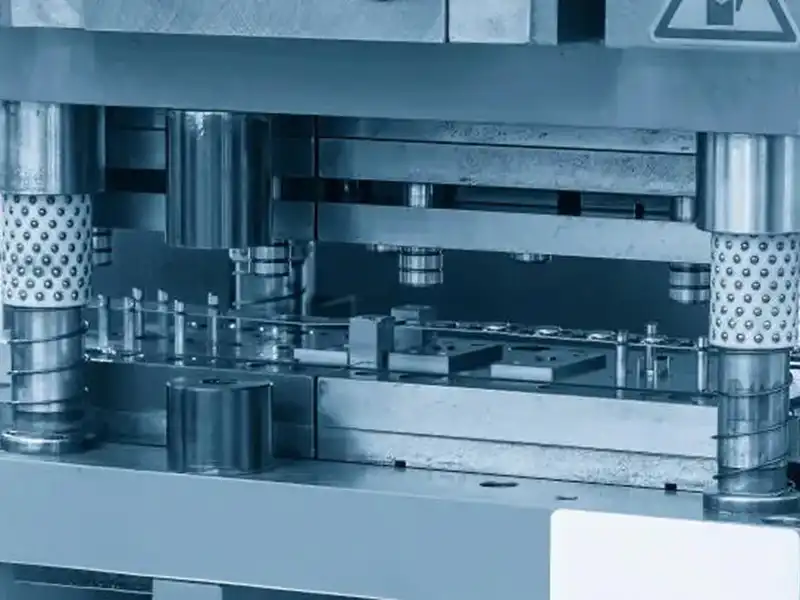

Manufacturing Process

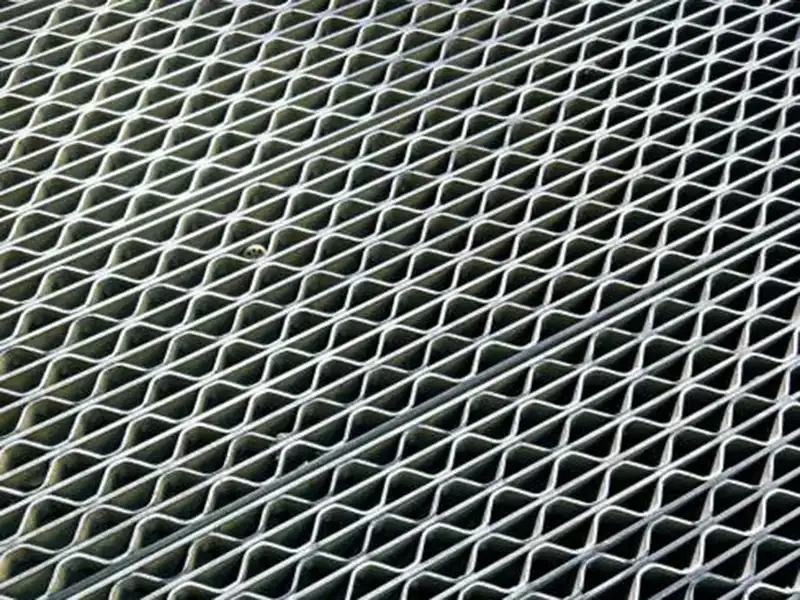

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

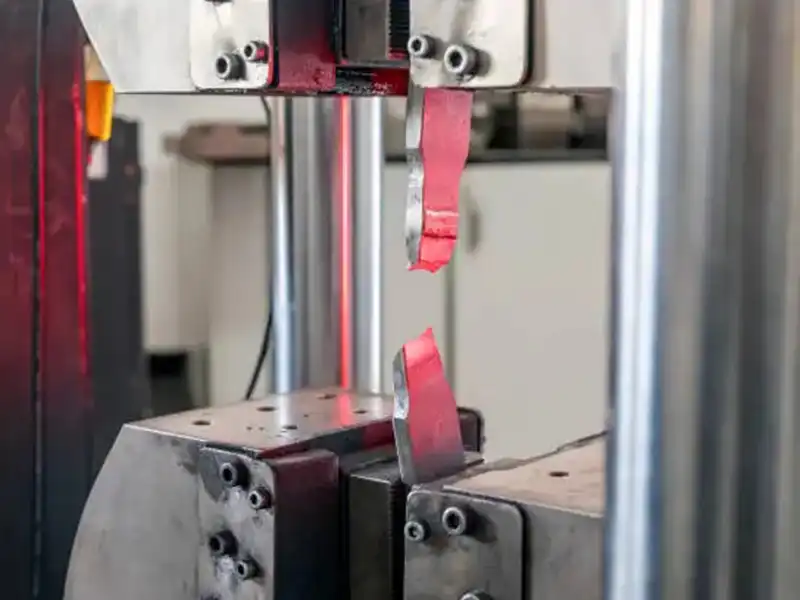

Pressing

High temperature sintering

Welding

Customization Options

At Shaanxi Filture New Material Co., Ltd., we recognize that different industries require specialized filtration solutions. Our Stainless Steel Sintering Filter Element can be customized to meet your exact needs, including:

Custom Sizes and Shapes: Designed and manufactured to match specific equipment or application requirements.

Material Selection: Available in stainless steel, titanium, nickel, and other alloys depending on industry demands.

Aperture Adjustments: Offered with a wide range of pore sizes to achieve optimal filtration efficiency.

Quality Assurance

Every filter element we deliver is subject to rigorous testing and inspection, ensuring stable performance under the most demanding conditions. Our manufacturing processes comply with international standards such as ISO, CE, and FDA, guaranteeing high reliability and consistent quality.

Packaging and Logistics

To ensure products arrive in perfect condition, each filter element is securely packaged against damage during transport. We provide flexible global logistics solutions, ensuring safe and timely delivery to customers worldwide.

Customer Support

Our dedication to service extends beyond the sale. From pre-sales consultation to after-sales technical support, installation guidance, and troubleshooting, our team ensures you get the most value from your filter elements.

Why Choose Us?

Industry Expertise: Years of experience and advanced sintering technology applied to every solution.

Tailored Solutions: Flexible customization to match diverse industrial requirements.

Strict Quality Control: Comprehensive inspection and compliance with global standards.

Worldwide Service: Reliable support and on-time delivery across Europe, North America, Asia-Pacific, and the Middle East.

OEM Services

We provide OEM solutions, enabling customers to brand and specify technical requirements for Stainless Steel Sintering Filter Element according to their market needs.

FAQ

Q: What industries commonly use these filter elements?

A: They are widely applied in petrochemical, aerospace, pharmaceutical, food and beverage, and energy sectors.

Q: Can I order filters in specific dimensions or shapes?

A: Yes, we offer complete customization to fit your operational requirements.

Q: Are the filter elements suitable for high-temperature environments?

A: Absolutely. They can withstand temperatures up to 600°C while maintaining filtration efficiency.

Contact Details

Ready to optimize your filtration system with high-quality stainless steel sintered filters? Contact us today:

- Email: sam.young@sintered-metal.com

- Phone/Whatsapp: +8615877694221

Let Shaanxi Filture New Material Co., Ltd. provide you with the filtration solutions your business needs!

VIEW MORE316l Stainless Steel Sintered Porous Metal Filter Element

VIEW MORE316l Stainless Steel Sintered Porous Metal Filter Element VIEW MORETItanium Sintered Porous Metal Filter Element

VIEW MORETItanium Sintered Porous Metal Filter Element VIEW MORESintered Titanium Steam Filter Element

VIEW MORESintered Titanium Steam Filter Element VIEW MOREHigh Quality Titanium Filter Element

VIEW MOREHigh Quality Titanium Filter Element VIEW MORETitanium Cartridge Filter Element

VIEW MORETitanium Cartridge Filter Element VIEW MORESterile Stainless Steel Filter Elements

VIEW MORESterile Stainless Steel Filter Elements VIEW MORESS Sintered Filter

VIEW MORESS Sintered Filter VIEW MORESintered Metal Filter Elements

VIEW MORESintered Metal Filter Elements

_1742364652633.webp)