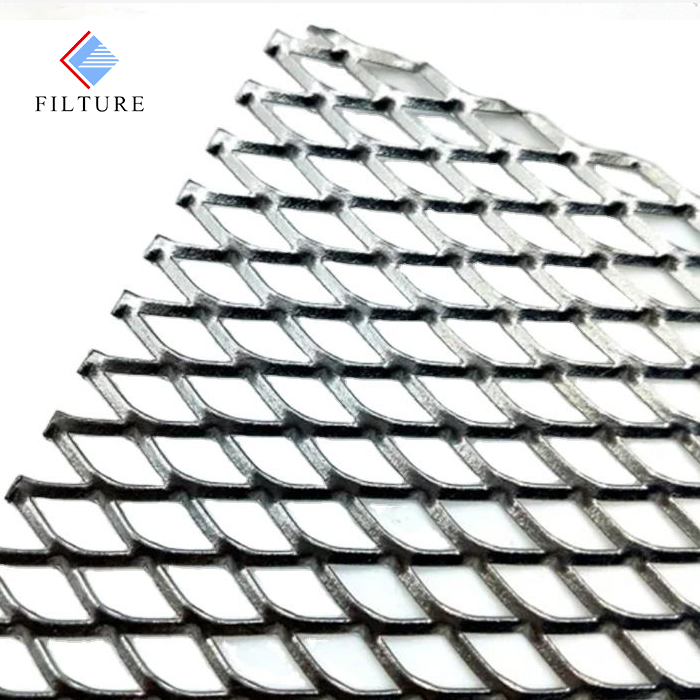

Industrial Titanium Mesh Panels

Superior durability for harsh chemical and marine environments.

Good conductivity and stability for electrolysis applications.

Heat-resistant and non-magnetic for aerospace and medical use.

Uniform structure with excellent mechanical performance.

- Product Description

Industrial Titanium Mesh Panels: Premium Solutions for Your Industry Needs

Product Introduction

Engineered for high-performance filtration in extreme conditions, this solution offers exceptional strength, durability, and resistance to corrosion. Capable of withstanding high temperatures, intense pressure, and aggressive environments, these sintered metal filters deliver reliable results where conventional materials fail. Thanks to titanium’s inherent resistance to oxidation and chemical attack, Industrial Titanium Mesh Panels provide consistent performance in the most demanding applications, making them an excellent choice for aerospace, energy, chemical, and medical industries.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Titanium Alloy (Grade 1, Grade 2) |

| Filtration Efficiency | ≥99% |

| Operating Temperature | -50°C to 800°C |

| Operating Pressure | Up to 50 MPa |

| Thickness | 0.5mm - 5mm |

| Density | 3.0 g/cm³ |

| Chemical Resistance | Highly resistant to acids, alkalis, and chlorides |

| Structure | Multi-layer, sintered mesh |

Product Features (Key Features)

- High Porosity: The intricate design allows for superior airflow and filtration efficiency.

- Durability: Titanium’s natural strength ensures longevity and minimizes the need for frequent replacements.

- Corrosion Resistance: Titanium provides outstanding protection against corrosive chemicals, high temperatures, and other aggressive substances.

- Pressure and Temperature Resistance: These panels are built to withstand extreme pressure and temperature conditions, making them ideal for industrial applications.

- Easy Maintenance: Designed for easy cleaning and reuse, reducing operational costs over time.

Applications

Our Industrial Titanium Mesh Panels are widely utilized across multiple industries, each benefiting from their exceptional performance:

Petrochemical Industry: Suitable for filtration equipment exposed to high heat and corrosive chemicals.

Pharmaceutical Industry: Critical for separation and purification in complex production processes.

Food and Beverage: Provides fine filtration to ensure purity and compliance with hygiene standards.

Aerospace: Lightweight yet strong, making them ideal for filtration systems in high-stress environments.

Energy and Chemicals: Perfect for oil, gas, and power generation filtration systems that demand high resistance to temperature and pressure.

Manufacturing Process

These titanium filter panels are produced through a precision sintering process, where titanium powder is fused under controlled heat and pressure. This results in a strong, multi-layered structure with excellent uniformity and structural integrity. The process also allows for accurate control of pore size and filtration performance, and additional molding techniques can be applied to meet specialized application requirements.

Customization Options

Understanding that industries have diverse needs, we provide tailored solutions for Industrial Titanium Mesh Panels, including:

Size: Custom dimensions to fit specific equipment.

Pore Size: Adjustable apertures for varied filtration demands.

Shape: Available in round, square, or customized geometries.

Material Options: Besides titanium, we also offer stainless steel and nickel alternatives.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality is at the core of our operations. Every Industrial Titanium Mesh Panel is manufactured under strict quality control systems and certified to international standards such as ISO, CE, and FDA. Comprehensive testing ensures consistent durability, corrosion resistance, and reliability under extreme pressures and temperatures.

Packaging and Logistics

To prevent damage in transit, each sintered titanium mesh panel is securely packaged with protective materials. Our logistics team provides fast and reliable delivery worldwide, offering flexible shipping solutions to match customer requirements.

Customer Support

We are dedicated to providing complete support before, during, and after purchase. From product selection and technical guidance to troubleshooting and maintenance, our experts ensure smooth integration into your systems.

Contact us at sam.young@sintered-metal.com for tailored assistance.

Why Choose Us

With years of experience in advanced filtration solutions, we are trusted by global industries for reliability and cost efficiency. Our strength lies in customization, strict quality control, and customer-centric service, making us a dependable partner for long-term cooperation.

OEM Services

We provide full OEM services, enabling clients to create Industrial Titanium Mesh Panels designed to exact specifications. From size and material selection to special designs, our engineering team delivers tailored solutions.

Frequently Asked Questions (FAQs)

Q: What industries can use these panels?

A: They are applied in aerospace, petrochemicals, pharmaceuticals, food processing, and energy production.

Q: Are they reusable?

A: Yes, the panels are designed for easy cleaning and long-term use, reducing replacement costs.

Q: Do you offer custom sizes?

A: Absolutely. We provide customized sizes, shapes, and pore configurations.

Q: What is the maximum operating temperature?

A: The panels can withstand up to 800°C, making them suitable for high-temperature environments.

Contact Details

For inquiries, please reach out to us at:

Email: sam.young@sintered-metal.com

Tel/Whatsapp: +8615877694221

Let us help you find the perfect solution for your filtration needs with Industrial Titanium Mesh Panels. Contact us today!

_1742364652633.webp)