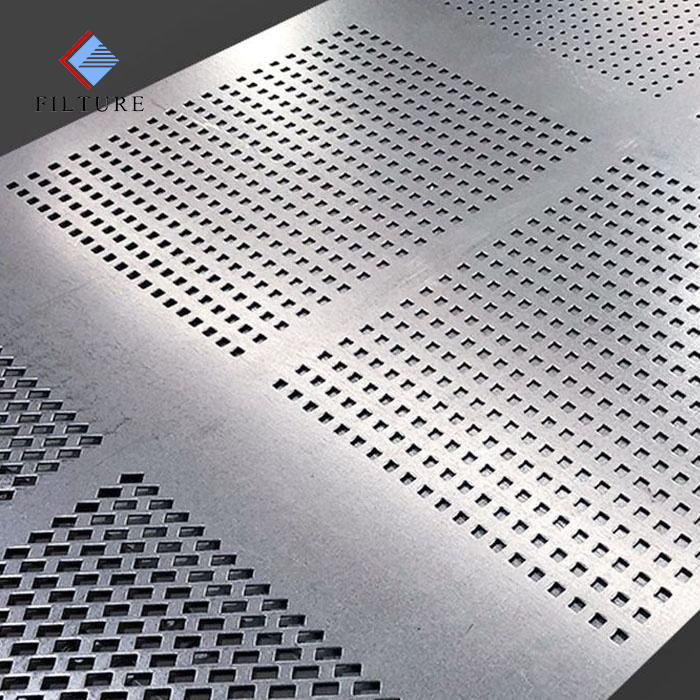

Corrosion-Resistant Titanium Perforated Plate

Outstanding corrosion and heat resistance for harsh environments.

Precise hole patterns for optimized filtration and ventilation.

Good conductivity and stability for electrochemical applications.

Versatile use in aerospace, medical, and industrial fields.

- Product Description

Corrosion-Resistant Titanium Perforated Plate

Product Introduction

Are you searching for a high-performance material that offers exceptional durability, corrosion resistance, and adaptability for demanding applications? Look no further than our Corrosion-Resistant Titanium Perforated Plate. Designed to excel in extreme environments, this advanced material is the perfect solution for industries requiring superior filtration, structural integrity, and reliability under high-temperature and high-pressure conditions. Whether you're in the chemical, aerospace, or medical sectors, our titanium perforated plates deliver unparalleled efficiency and performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Pure Titanium (Grade 1, Grade 2) |

| Corrosion Resistance | Outstanding in acidic and alkaline environments |

| Thickness Range | 0.5 mm – 10 mm |

| Pore Size Range | 0.1 mm – 10 mm |

| Filtration Efficiency | Up to 99.8% for fine particles |

| Operating Temperature | -200°C to 600°C |

| Operating Pressure | Up to 10 MPa |

| Certification | ISO 9001, CE, FDA |

Product Features

High Corrosion Resistance: Engineered to withstand harsh chemical environments, including exposure to acids, alkalis, and seawater.

Exceptional Strength: Maintains structural integrity under extreme pressure and temperature conditions.

High Porosity: Ensures optimal breathability and filtration efficiency.

Easy Maintenance: Designed for easy cleaning, reuse, and minimal downtime.

Long Service Life: Durable material reduces replacement frequency, saving costs over time.

Applications

The Corrosion-Resistant Titanium Perforated Plate is versatile and indispensable in industries such as:

Chemical Processing: For gas separation, catalyst support, and filtration in corrosive environments.

Aerospace: Lightweight, durable solutions for advanced structural and filtration needs.

Medical Devices: FDA-certified material for safe and reliable use in medical filtration and implants.

Energy Sector: Efficient filtration for oil, gas, and renewable energy applications.

Food & Beverage: Hygienic filtration solutions ensuring purity and safety.

Manufacturing Process

Our titanium perforated plates are crafted using an advanced sintering and forming process. This involves layering titanium powders, compressing them, and applying high-temperature sintering. The result is a highly uniform and durable product with precise pore sizes and exceptional strength. Multi-layer structures and special molding processes can be customized for enhanced performance.

Customization Options

We understand that every application is unique. That’s why we offer fully customizable solutions:

Material Grades: Pure titanium or titanium alloys.

Pore Sizes: Tailored to meet specific filtration needs.

Shapes and Dimensions: Custom sizes, thicknesses, and designs.

Additional Features: Multi-layer construction, special coatings, and more.

Quality Assurance

Our products undergo rigorous quality control to ensure consistent performance and reliability:

Certifications: ISO 9001, CE, and FDA compliance.

Testing Procedures: Thorough inspection for pore size accuracy, corrosion resistance, and mechanical strength.

Traceability: Each batch is documented for material origin and manufacturing processes.

Packaging and Logistics

Secure Packaging: Customized protective packaging prevents damage during transit.

Global Logistics: Flexible shipping options to meet your delivery deadlines.

Tracking Support: Real-time updates on shipment status.

Customer Support

We are committed to providing exceptional support before, during, and after your purchase:

Technical Assistance: From product selection to installation guidance.

After-Sales Support: Dedicated team to resolve issues promptly.

Contact Us: Reach us at sam.young@sintered-metal.com or call/WhatsApp +8615877694221 for assistance.

Why Choose Us

Industry Expertise: Decades of experience in manufacturing advanced filtration materials.

Customization Excellence: Tailored solutions for your unique operational needs.

Global Reach: Reliable supply chain and logistics for on-time delivery worldwide.

Quality You Can Trust: Stringent quality control and certifications for consistent performance.

OEM Services

Partner with us for tailored manufacturing solutions:

Custom Designs: Adapt specifications to meet your project requirements.

Private Labeling: Strengthen your brand with customized packaging and labeling.

Frequently Asked Questions (FAQs)

Q: Can the titanium perforated plate withstand extreme temperatures?

A: Yes, our plates operate effectively between -200°C and 600°C.

Q: Are these plates reusable?

A: Absolutely. They are easy to clean and designed for multiple uses.

Q: Do you provide samples?

A: Yes, we can provide samples for evaluation upon request.

Q: What industries are best suited for this product?

A: Industries like aerospace, chemical processing, energy, and medical sectors benefit greatly from our titanium perforated plates.

Contact Details

For inquiries or assistance, contact us:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: +8615877694221

_1742364652633.webp)