High-Durability Titanium Perforated Panels

Outstanding corrosion and heat resistance for harsh environments.

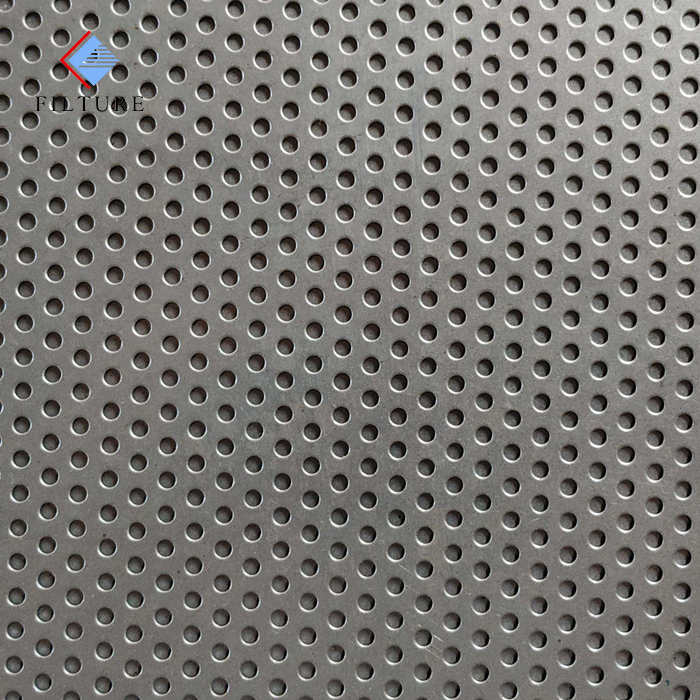

Precise hole patterns for optimized filtration and ventilation.

Good conductivity and stability for electrochemical applications.

Versatile use in aerospace, medical, and industrial fields.

- Product Description

High-Durability Titanium Perforated Panels

Product Introduction

High-Durability Titanium Perforated Panels are the gold standard for industries requiring advanced filtration, superior durability, and precise performance. Engineered for extreme conditions, these panels offer exceptional resistance to high temperatures, corrosive environments, and heavy mechanical loads. They excel in applications ranging from petrochemical processing to aerospace, ensuring efficiency and reliability where it matters most.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Pure Titanium (Grade 1, 2) |

| Thickness Range | 0.5mm - 5mm |

| Filtration Efficiency | Up to 99.9% |

| Operating Temperature | -200°C to 600°C |

| Operating Pressure | Up to 5 MPa |

| Surface Finish | Polished or Customized |

| Certification | ISO 9001, CE |

Product Features

Exceptional Durability: With titanium’s natural strength and corrosion resistance, these panels are built to withstand demanding environments.

High Porosity: Optimized pore structures ensure superior breathability and filtration efficiency.

Temperature & Pressure Resistant: Performs reliably in extreme temperatures and high-pressure applications.

Reusable & Eco-Friendly: Easy to clean and reuse, minimizing maintenance costs and environmental impact.

Customization Options: Available in various sizes, shapes, and pore configurations to suit specific needs.

Applications

High-Durability Titanium Perforated Panels are versatile and ideal for:

Petrochemical Industry: Used in filtration systems for refining and gas separation processes.

Medical Field: Supporting sterile filtration for medical devices and life science equipment.

Aerospace: Lightweight, high-strength components for advanced filtration and ventilation.

Energy Sector: Efficient filtration in oil, gas, and power generation equipment.

Chemical Processing: Applied in catalytic reactions, separation processes, and corrosive environments.

Food and Beverage: Ensures precision filtration for liquids and gases in food-grade applications.

Manufacturing Process

The panels are meticulously crafted using an advanced sintering process:

Material Selection: High-quality titanium is sourced for maximum purity and strength.

Perforation: Precision tools create evenly distributed pore structures.

Sintering: Layers are bonded under high heat and pressure to enhance structural stability.

Quality Inspection: Rigorous testing ensures compliance with international standards.

Customization Options

Our High-Durability Titanium Perforated Panels can be tailored to your specific requirements:

Sizes and Shapes: Custom dimensions and geometries.

Pore Configurations: Adjust pore size and distribution to meet precise filtration needs.

Material Grades: Options for various titanium grades to suit application demands.

Quality Assurance

Certifications: ISO 9001 and CE certified.

Testing Protocols: Each panel undergoes rigorous testing for durability, filtration efficiency, and material consistency.

Traceability: Every batch is documented for full traceability and compliance.

Packaging and Logistics

Our products are securely packaged to prevent damage during transportation. Options include:

Shockproof and moisture-resistant packaging.

Global delivery within 7-15 business days, depending on location.

Customer Support

Our dedicated team is here to assist you at every step:

Pre-Sales Support: Expert consultations to determine the best solution for your needs.

After-Sales Service: Comprehensive technical support for installation and maintenance.

Contact Us: Email: sam.young@sintered-metal.com | Tel/WhatsApp: +8615877694221

Why Choose Us?

Industry Expertise: Over 10 years of experience in advanced material solutions.

Custom Manufacturing: Flexible production capabilities tailored to your needs.

Certified Quality: Internationally recognized certifications and rigorous quality control.

Reliable Supply Chain: On-time delivery with global logistics support.

Comprehensive Support: End-to-end technical assistance for every customer.

OEM Services

We specialize in providing custom OEM solutions:

Develop tailored panel designs.

Collaborate on innovative material solutions for your applications.

Frequently Asked Questions (FAQs)

Q: What industries benefit most from titanium perforated panels? A: These panels are ideal for petrochemical, aerospace, medical, energy, and food industries.

Q: Can you customize pore size and panel thickness? A: Absolutely! We offer full customization to meet your specific requirements.

Q: Are the panels reusable? A: Yes, they are designed for easy cleaning and reuse, reducing long-term costs.

Q: How quickly can I receive my order? A: Delivery times range from 7-15 business days, depending on your location.

Q: What certifications do your products have? A: Our panels are ISO 9001 and CE certified, ensuring top-quality standards.

Contact Details

Direct Contact:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: +8615877694221

_1742364652633.webp)