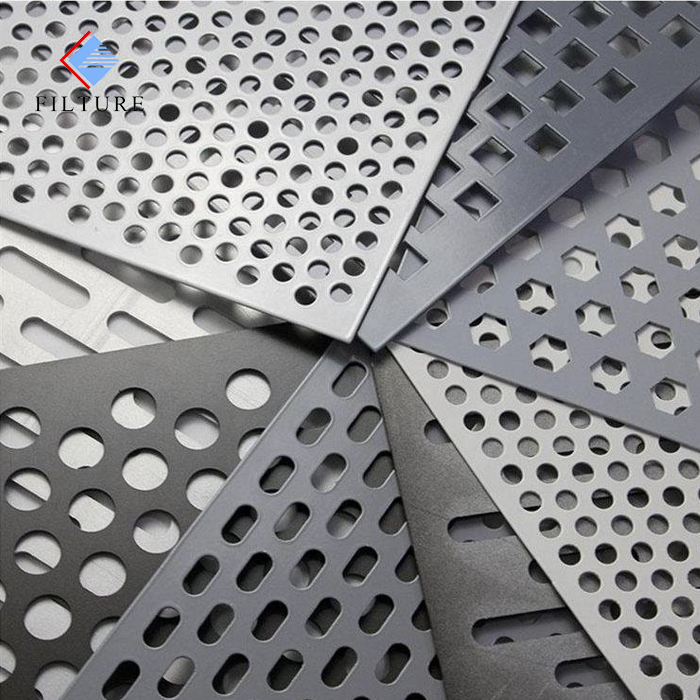

Titanium Perforated Plates For Industry

Outstanding corrosion and heat resistance for harsh environments.

Precise hole patterns for optimized filtration and ventilation.

Good conductivity and stability for electrochemical applications.

Versatile use in aerospace, medical, and industrial fields.

- Product Description

Product Introduction

Titanium Perforated Plates For Industry offer an excellent solution for filtration systems in demanding industrial environments. Known for their high-temperature tolerance, corrosion resistance, and structural integrity, these plates provide reliable performance under high-pressure conditions. Ideal for aerospace, energy, and medical applications, they ensure efficient filtration, superior breathability, and long-lasting durability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Pure Titanium (Grade 1, 2) |

| Pore Size Range | Customized |

| Thickness | 0.5 mm to 10 mm |

| Operating Temperature | -200°C to 600°C |

| Pressure Resistance | Up to 3 MPa |

| Corrosion Resistance | Excellent in acids, alkalis, and salts |

| Customization Options | Sizes, shapes, and pore distributions |

Product Features

High Porosity: Ensures optimal permeability for superior filtration and breathability.

Durability: Long service life with excellent resistance to wear and tear.

Corrosion Resistance: Performs reliably in acidic, alkaline, and other harsh environments.

High-Temperature Stability: Operates efficiently at extreme temperatures.

Easy Maintenance: Panels are simple to clean and reusable, reducing costs.

Customizable Design: Tailored to meet unique operational requirements.

Applications

Our Titanium Perforated Plates For Industry are used widely in:

Energy Sector: Gas and liquid separation in oil, gas, and power generation.

Chemical Industry: Catalyst recovery, gas purification, and separation processes.

Aerospace: Lightweight yet strong plates for air filtration and cooling systems.

Medical Devices: Certified plates for surgical tools and sterilization filters.

Food & Beverage: Fine filtration ensuring hygiene and safety standards.

Manufacturing Process

These plates are produced using advanced sintering and forming techniques, ensuring uniform pore distribution and high structural integrity. Multi-layer configurations and specialized molding enhance durability and filtration performance. This meticulous process guarantees consistent quality across all applications.

Customization Options

We provide flexible customization to meet specific project requirements:

Material Options: Pure titanium or titanium alloys.

Size and Shape: Panels fabricated to any dimensions or design.

Pore Configuration: Custom pore sizes and patterns for precise filtration.

Additional Features: Multi-layer structures or reinforced edges for extra strength.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality is paramount:

Certifications: ISO 9001, CE, and FDA compliant.

Inspection: Rigorous testing ensures filtration efficiency, durability, and reliability.

Consistency: Strict quality control guarantees uniform performance across batches.

Packaging and Logistics

Secure Packaging: Each plate is carefully wrapped to prevent damage during transit.

Global Logistics: Fast, reliable delivery for domestic and international clients.

Delivery Time: Typically 7–15 business days depending on order size.

Customer Support

We offer full support to ensure satisfaction:

Pre-Sales Consultation: Expert guidance to select the right plates.

After-Sales Assistance: Help with installation, maintenance, and troubleshooting.

Contact: Email sam.young@sintered-metal.com or call/WhatsApp +8615877694221.

Why Choose Us?

Experience: Over a decade of expertise in producing high-quality titanium filtration products.

Innovation: Advanced R&D for cutting-edge industrial solutions.

Customization: Flexible production tailored to your requirements.

Reliability: Proven track record for on-time delivery and consistent quality.

Customer Focus: Dedicated team committed to your success.

OEM Services

We provide tailored OEM solutions for your business. From design to production, we collaborate closely to develop Titanium Perforated Plates For Industry that match your exact specifications. Our flexible manufacturing ensures high-quality, cost-effective results.

FAQ

Q1: What industries use these plates?

A: They are widely used in energy, aerospace, medical, food & beverage, and chemical industries.

Q2: Can you customize pore size and shape?

A: Yes, fully customizable options are available.

Q3: Are the plates reusable?

A: Yes, they are durable and easy to clean.

Q4: What certifications do you hold?

A: All products comply with ISO 9001, CE, and FDA standards.

Contact Us

For inquiries about Titanium Perforated Plates For Industry, please contact:

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +861587769422

_1742364652633.webp)