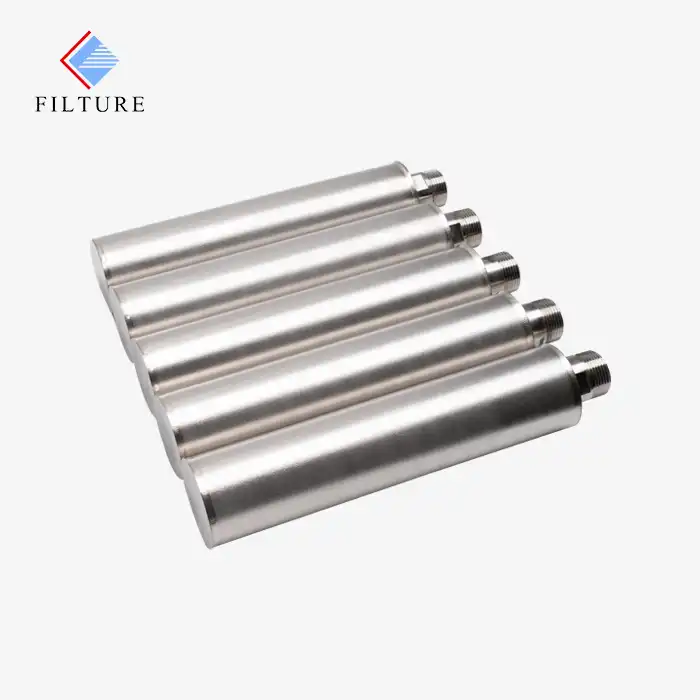

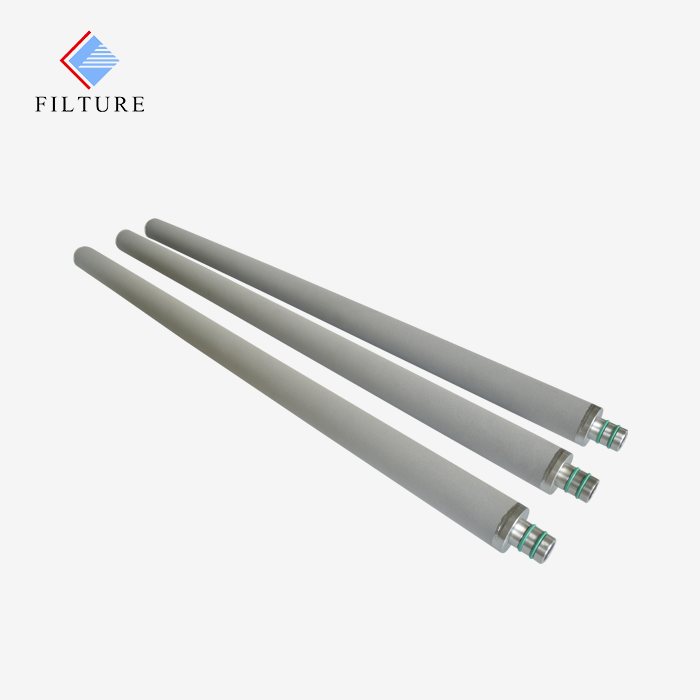

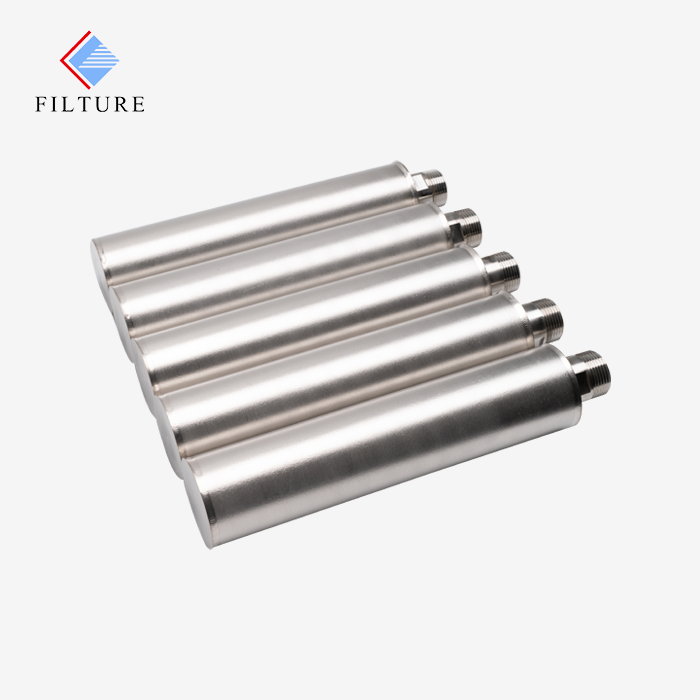

Sintered Stainless Steel Filter Cartridge

Absolute Rate :Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length:

254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: 0.22-100um

- Product Description

Sintered Stainless Filters: High-Performance Solutions for Demanding Industries

Welcome to our premium Sintered Stainless Steel Filter Cartridge, engineered to deliver outstanding performance for industries with demanding filtration requirements. Built with excellent resistance to high temperatures, corrosion, and pressure, it offers unmatched durability, reliability, and filtration precision even in the harshest environments. Designed to serve industrial manufacturers, research facilities, and specialized sectors such as aerospace and medical devices, this filter cartridge ensures consistent and efficient operation in complex applications.

Technical Specifications

| Specification | Details |

|---|---|

| Materials | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 1-100 microns |

| Filtration Efficiency | 99.99% |

| Operating Temperature | Up to 800°C |

| Operating Pressure | Up to 100 bar |

| Size | Customizable |

| Shape | Disc, Plate, Tube, Custom Shapes |

| Thickness | 1mm to 10mm |

Our products are available in a variety of materials such as stainless steel, titanium, and nickel, making them ideal for diverse applications. The range of pore sizes and high filtration efficiency ensures that even the most demanding filtration needs are met.

|  |  |  |

|  |  |  |

Product Features

High Porosity: With precise control over pore size and distribution, the Sintered Stainless Steel Filter Cartridge delivers excellent permeability while maintaining strength and durability.

Durability & Longevity: Resistant to high temperatures, extreme pressures, and corrosive environments, ensuring reliable long-term performance.

Easy Cleaning & Reusability: Designed for cost-effective operations, the cartridge can be easily cleaned and reused without losing efficiency.

Customization: Tailored solutions available, including custom sizes, shapes, and materials to meet unique application needs.

These advantages make the filter cartridge a trusted choice for industries such as petrochemical, pharmaceuticals, aerospace, and medical device manufacturing.

Applications of Sintered Stainless Steel Filter Cartridge

Engineered to meet precise industrial requirements, this advanced cartridge plays a vital role in:

Petrochemical Industry: Applied in oil, gas, and power generation systems to remove impurities and maintain operational efficiency.

Pharmaceutical & Medical Fields: Essential for sterile filtration in drug manufacturing, medical devices, and life sciences equipment where reliability is critical.

Food & Beverage Industry: Ensures purity in liquid and air filtration during food processing, preventing contamination.

Gas Filtration: Provides high-precision filtration for separating fine particles and pollutants in chemical processing, aerospace, and energy sectors.

Manufacturing Process

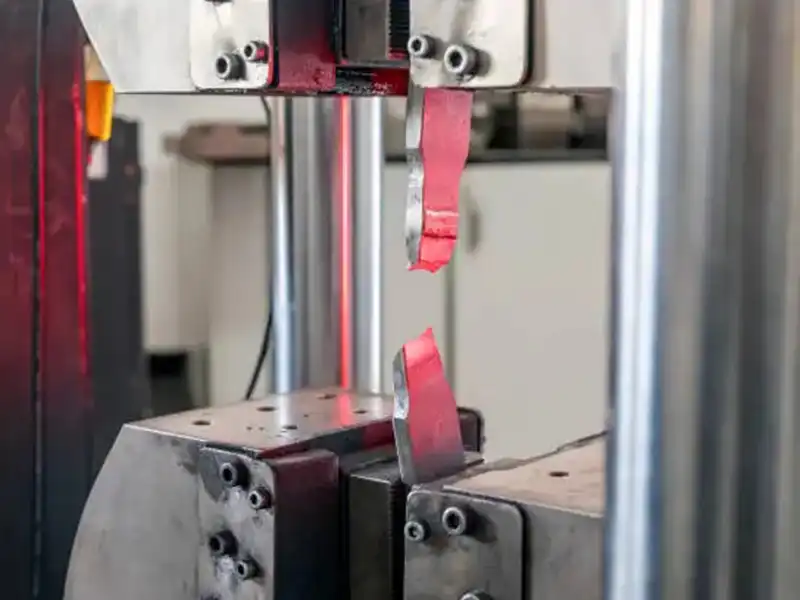

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

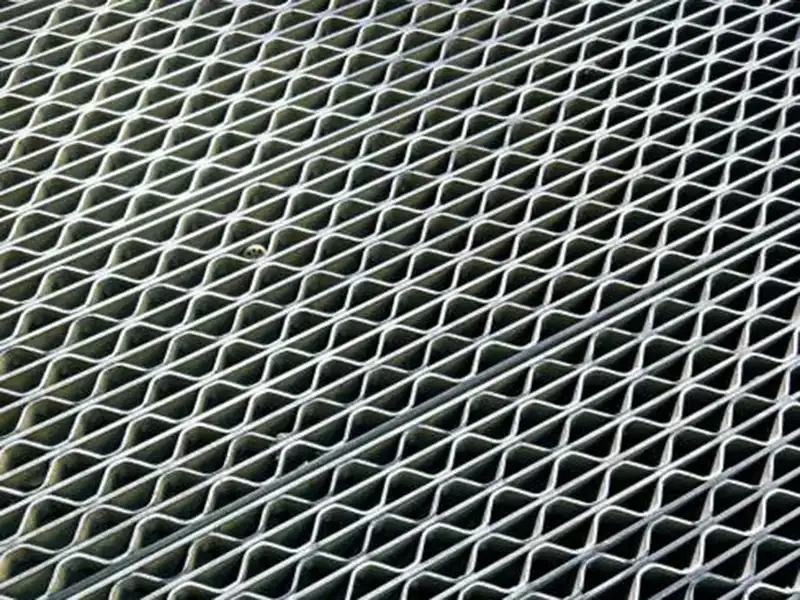

Metal Mesh

Titanium and Stainless Steel metal fibers

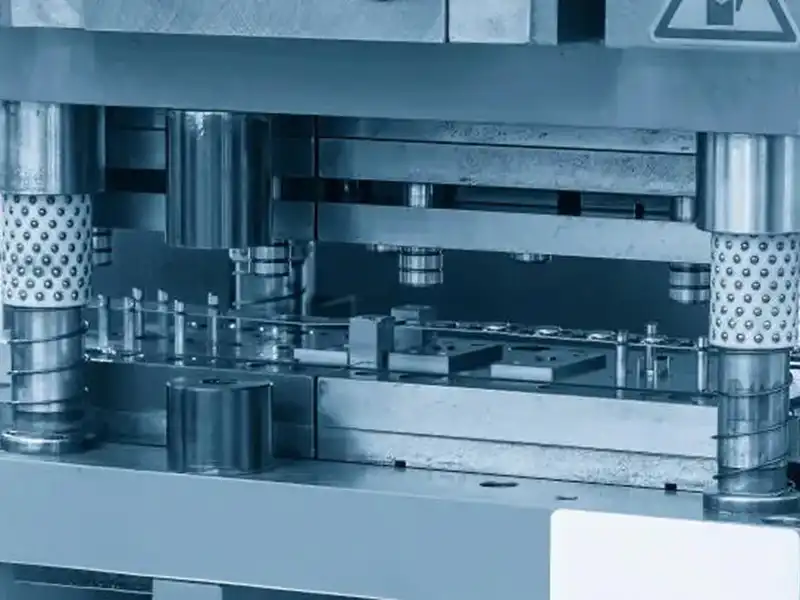

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We provide comprehensive customization services to ensure each Sintered Stainless Steel Filter Cartridge meets your exact operational requirements:

Custom Sizes and Shapes: Designed to fit your system’s specifications with precision.

Aperture Sizes: Available in a wide range of pore sizes to match diverse filtration needs.

Material Options: Choose from stainless steel, titanium, and other high-performance alloys to suit your application.

Quality Assurance

Our filter cartridges are manufactured under strict quality control standards to guarantee durability, reliability, and top-level performance. Every unit is tested for extreme operating conditions and complies with international certifications, including ISO, CE, and FDA.

Packaging and Logistics

Each filter cartridge is securely packaged to prevent damage during shipment. With efficient global shipping and flexible logistics options, we ensure safe and timely delivery to customers across Europe, North America, Asia-Pacific, and the Middle East.

Customer Support

We are committed to supporting customers throughout the entire process. Our services include:

Technical Guidance: Assistance with product selection, installation, and system optimization.

Training & Workshops: Practical sessions to help operators maintain and maximize filtration efficiency.

For inquiries, please contact us at sam.young@sintered-metal.com.

Why Choose Us?

With extensive experience in advanced filtration, we have earned the trust of industries worldwide. What sets us apart:

Tailored Production: Customized designs to meet unique industry requirements.

Reliable Delivery: Flexible shipping schedules to fulfill global demand.

Dedicated Service: End-to-end customer care, from consultation to after-sales support.

OEM Services

We offer OEM manufacturing, enabling customers to specify designs, dimensions, and materials for high-quality, precision-engineered filtration solutions.

FAQ

Q: What is the maximum operating temperature of your products?

A: Our filter cartridges are engineered to withstand temperatures up to 800°C.

Q: Can I customize a filter for my specific system?

A: Yes, the Sintered Stainless Steel Filter Cartridge can be fully customized in size, shape, aperture, and material to meet your operational needs.

Contact Us

For more information, quotes, or technical support, please don’t hesitate to contact us directly at:

- Email: sam.young@sintered-metal.com

- Tel/Whatsapp: +8615877694221

Let us provide you with the high-quality, customized filtration solutions you need!

VIEW MORETItanium Sintered Porous Metal Filter Element

VIEW MORETItanium Sintered Porous Metal Filter Element VIEW MOREStainless Steel Sintered Filter Element

VIEW MOREStainless Steel Sintered Filter Element VIEW MORETitanium Sintered Filter Element

VIEW MORETitanium Sintered Filter Element VIEW MOREHigh Quality Titanium Filter Element

VIEW MOREHigh Quality Titanium Filter Element VIEW MOREStainless Steel Sintering Filter Element

VIEW MOREStainless Steel Sintering Filter Element VIEW MORESintered SS Filters

VIEW MORESintered SS Filters VIEW MORESintered Metal Filter Elements

VIEW MORESintered Metal Filter Elements VIEW MORESintered Filter Elements

VIEW MORESintered Filter Elements

_1742364652633.webp)