Metal Sintered Porous Disc

Cleanable

Available Sizes:

Outer Diameter: 10-300mm

Thickness: 1-3mm

Micron Rating: 0.22-100um

- Product Description

Metal Sintered Porous Disc: High-Performance Filtration for Demanding Applications

Welcome to our Metal Sintered Porous Disc, engineered to deliver high-quality, durable, and reliable filtration solutions. Built to perform efficiently under high temperatures, extreme pressures, and corrosive conditions, it ensures consistent operation in demanding environments.

Offering exceptional filtration and permeability, this porous disc is ideal for industries such as aerospace, energy, chemical, and medical applications. Discover why our sintered metal filters are the preferred choice for precise filtration and effective material separation.

Technical Specifications

| Parameter | Value |

|---|---|

| Material | Stainless Steel, Titanium, Nickel, etc. |

| Pore Size Range | 1μm to 100μm |

| Filtration Efficiency | Up to 99.9% |

| Operating Temperature | -200°C to 600°C |

| Operating Pressure | 0 to 200 bar |

| Thickness | 1 mm to 15 mm |

| Shape Options | Round, Square, Custom Shapes |

| Certification | ISO 9001, CE, FDA |

These specifications ensure that our metal sintered porous discs can be applied to various filtration processes requiring high efficiency and long-term performance.

|  |  |  |

|  |  |  |

Key Features

High Porosity: The sintering process produces a highly porous structure, enabling optimal flow and filtration while maintaining strong separation performance.

Durability: Built to endure extreme temperatures, pressures, and corrosive environments, ensuring long service life with minimal maintenance.

Corrosion and Temperature Resistance: Resistant to corrosion and capable of performing reliably under high temperatures, making it suitable for harsh industrial conditions.

Reusability: The Metal Sintered Porous Disc is easy to clean and reuse, offering a cost-effective solution with minimal downtime.

Customizable Sizes: Available in a variety of shapes and dimensions to match specific operational requirements.

Applications

These Metal Sintered Porous Discs are vital for industries requiring precise filtration:

Petrochemical Industry: Used in oil and gas processing to ensure fine particle separation and efficient filtration.

Pharmaceutical & Food & Beverage: Provides hygienic filtration for critical processes, including sterilization and separation.

Aerospace: Essential for high-performance aircraft and spacecraft systems, combining lightweight design with robust filtration.

Gas Filtration: Effectively removes particulates and contaminants from industrial and chemical gas streams.

Designed to meet the rigorous standards of these sectors, our sintered porous discs deliver reliable performance and superior quality in every application.

Manufacturing Process

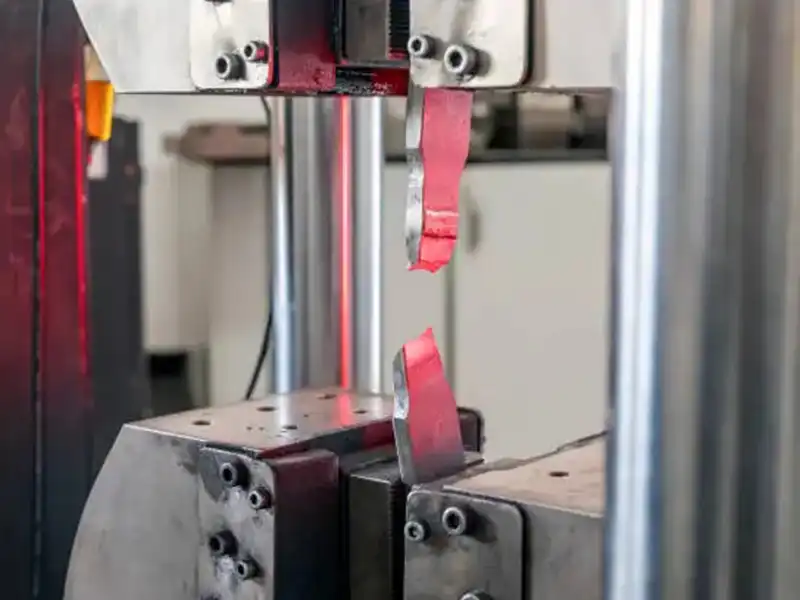

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

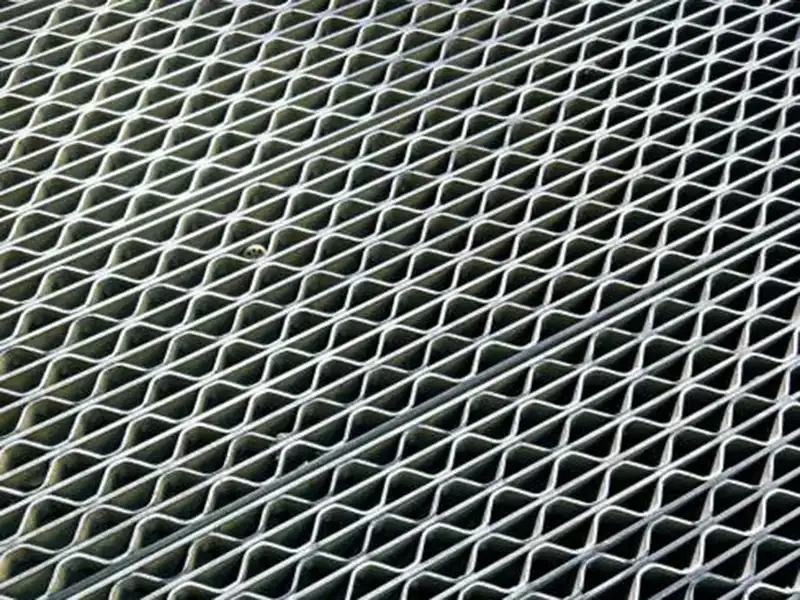

Metal Mesh

Titanium and Stainless Steel metal fibers

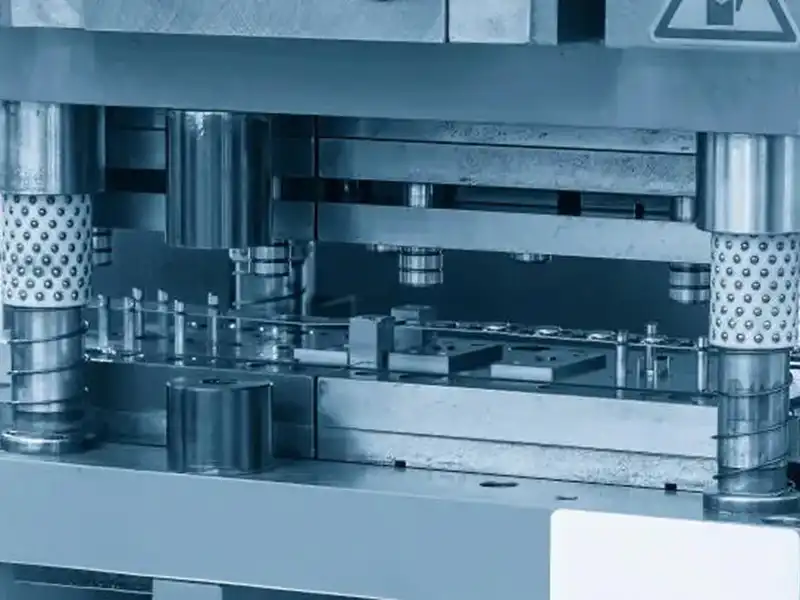

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every customer’s requirements are unique. That’s why we offer tailored solutions for the Metal Sintered Porous Disc, including:

Size: Fully customizable to fit your system, from small to large discs.

Aperture Size: Select the optimal pore size for your specific filtration process.

Material Choice: Available in stainless steel, titanium, nickel, and other alloys to suit your application.

Our flexible manufacturing capabilities ensure that each product is perfectly aligned with your operational needs.

Quality Assurance

We are committed to producing high-quality products that meet rigorous standards. Each disc undergoes thorough testing to guarantee consistency and reliability, including:

Comprehensive Testing: Evaluated for filtration efficiency, pressure tolerance, and durability under extreme conditions.

Certifications: ISO, CE, and FDA certifications confirm compliance with international quality and safety standards.

Packaging and Logistics

To ensure safe delivery, all discs are carefully packaged to prevent damage during transport. Our efficient logistics network guarantees timely delivery to customers worldwide.

Customer Support

Our dedicated team provides comprehensive support throughout your purchase and product lifecycle:

Pre-Sales Assistance: Technical guidance to help select the right product for your application.

After-Sales Support: Full support for installation, maintenance, and troubleshooting to ensure smooth operation.

For assistance, contact us at sam.young@sintered-metal.com.

Why Choose Us?

With years of experience and a strong commitment to quality, we are a trusted partner for industries requiring high-performance filtration. Our expertise in customizing metal sintered porous discs ensures solutions that meet your precise operational requirements.

Expert R&D: Innovating to provide advanced filtration solutions.

High Standards: Rigorous testing to ensure reliable performance.

Timely Delivery: Efficient supply chain to meet global demand.

OEM Services

We provide OEM solutions for clients needing custom sizes, materials, or unique designs, delivering precision-engineered filter discs tailored to your specifications.

FAQ

1. What is the maximum operating temperature?

Our discs operate reliably from -200°C to 600°C, suitable for extreme industrial conditions.

2. How do I clean and maintain the filters?

Designed for easy cleaning and reuse, regular maintenance with appropriate solvents or high-pressure air is recommended.

3. Can the pore size be customized?

Yes, pore sizes from 1μm to 100μm are available and can be tailored to your exact filtration requirements.

Contact Us

For inquiries or to discuss custom solutions for your business, contact us at:

- Email: sam.young@sintered-metal.com

- Phone/Whatsapp: +8615877694221

Explore the benefits of our metal sintered porous discs today and experience high-efficiency filtration tailored to your needs. Reach out to us for your customized filtration solution!

_1742364652633.webp)