Sintered Metal Filter Disc

Cleanable

Available Sizes:

Outer Diameter: 10-300mm

Thickness: 1-3mm

Micron Rating: 0.22-100um

- Product Description

Sintered Metal Filter Disc: High-Performance Filtration for Extreme Conditions

Discover the world of Sintered Metal Filter Disc, where precision filtration meets exceptional durability. These expertly engineered filter elements deliver reliable performance in demanding sectors such as petrochemicals, aerospace, medical devices, and energy production. With outstanding strength and efficiency, they maintain superior filtration even under extreme temperatures, pressures, and corrosive conditions.

At Shaanxi Filture New Material Co., Ltd., we provide comprehensive filtration solutions. Whether you require customized designs for specific operational challenges or high-quality standard products, our team ensures the perfect solution for your needs.

Technical Specifications

Our sintered metal filter discs offer cutting-edge performance in filtration applications. Below are the detailed specifications that make our filters the best choice for your industry:

| Parameter | Value |

|---|---|

| Materials | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.5 µm – 100 µm |

| Filtration Efficiency | Up to 99.99% |

| Operating Temperature | Up to 800°C (varies by material) |

| Operating Pressure | Up to 50 bar (depending on size) |

| Porosity | High, up to 40% |

| Thickness | 0.5 mm – 10 mm |

| Customization | Size, Shape, Aperture, Material |

Our sintered metal filter discs are engineered to meet the highest standards, ensuring consistent performance in the most demanding conditions.

|  |  |  |

|  |  |  |

Product Features (Key Features)

- High Durability: With exceptional resistance to high temperatures, corrosive chemicals, and high-pressure environments, sintered metal filters excel in longevity and reliability.

- Efficient Filtration: Offering outstanding filtration efficiency, these discs are capable of capturing even the smallest particles, making them ideal for fine filtration.

- Easy Cleaning & Reuse: Our sintered metal filter discs are easy to clean, reducing maintenance costs and improving operational efficiency.

- Customizable Design: Tailored solutions for your unique needs, including variations in size, material, and aperture.

- Superior Structural Stability: The sintering process gives these filters unmatched mechanical strength and resistance to deformation, ensuring a long-lasting performance under extreme conditions.

Applications

Our sintered metal filter discs are versatile and serve in a wide range of industries:

- Petrochemical: Essential for filtration in oil, gas, and petrochemical processing.

- Pharmaceutical: Used in medical filtration applications, ensuring the highest standards of purity.

- Food and Beverage: Ideal for separating unwanted particles and ensuring product quality.

- Aerospace: Lightweight yet strong, these filters are used in aircraft systems for fuel, air, and hydraulic filtration.

- Energy & Chemical Industries: Perfect for filtration in power generation, renewable energy, and chemical processing applications.

These filters are critical for ensuring that your equipment runs smoothly and your products meet the highest standards of quality.

Manufacturing Process

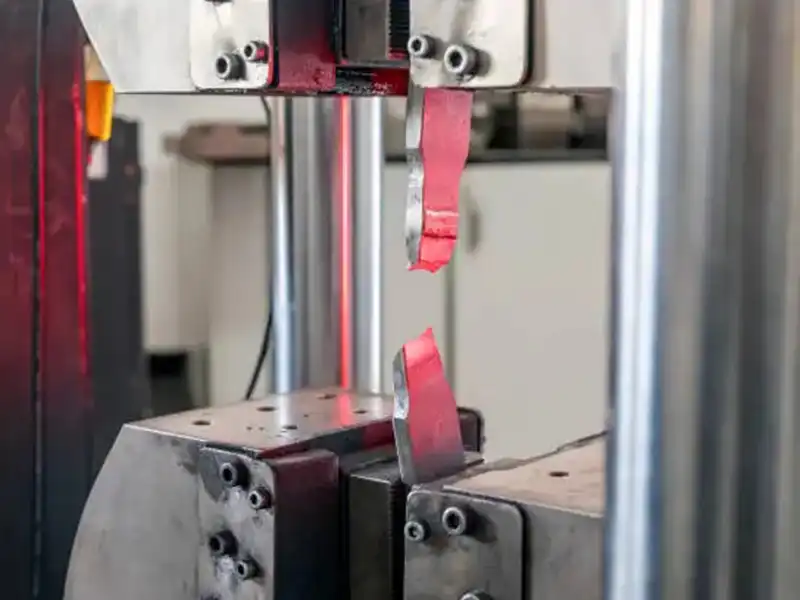

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

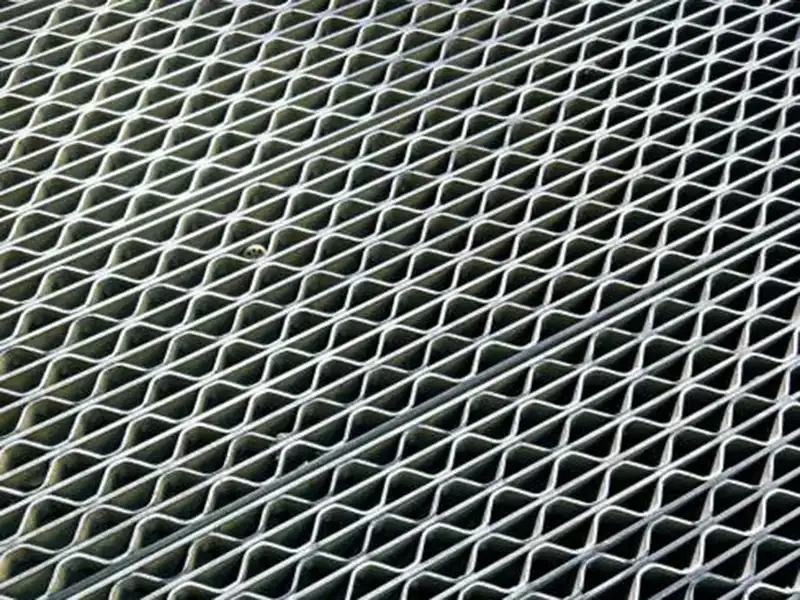

Metal Mesh

Titanium and Stainless Steel metal fibers

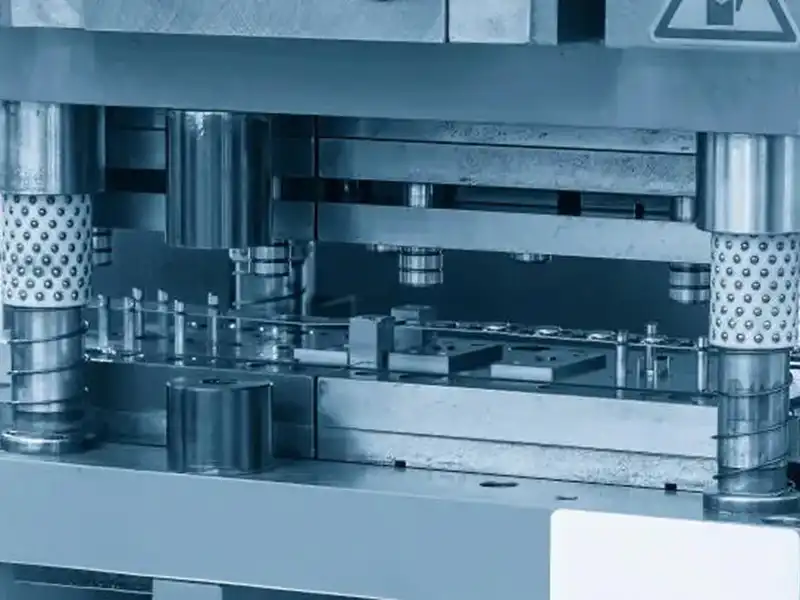

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We recognize that each customer has unique requirements, which is why we offer tailored solutions for Sintered Metal Filter Disc. You can select from a wide range of:

Materials: Stainless steel, titanium, nickel, and other high-performance alloys.

Sizes and Shapes: Custom dimensions and configurations to match your exact specifications.

Apertures: A variety of pore sizes to achieve optimal filtration efficiency.

Our flexible manufacturing capabilities allow us to tackle even the most complex filtration challenges with precision.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality is our top priority. Each product undergoes rigorous inspection and testing to meet international standards, including ISO, CE, and FDA compliance for medical applications. By maintaining strict quality control, we ensure every filter disc delivers reliable performance and long-term durability.

Packaging and Logistics

We take special care in packaging to prevent damage during transit. Our protective packaging and efficient logistics solutions guarantee that your filter arrives safely and on schedule, no matter where you are located globally.

Customer Support

Our dedicated team provides comprehensive support from pre-sales consultation to post-sales assistance. We guide you through product selection, installation, and maintenance to ensure smooth operation. Contact us at:

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +8615877694221

Why Choose Us

Expertise: Years of experience in the filtration industry, serving global clients.

Customization: Tailored solutions to meet your precise requirements.

Reliability: On-time delivery and consistent high-quality performance.

Technical Support: Professional guidance and assistance whenever needed.

OEM Services

We offer OEM manufacturing, allowing you to specify materials, dimensions, and designs to produce high-quality sintered metal filter elements that perfectly suit your application needs.

FAQ

Q: Which industries use these filters?

A: They are widely applied in petrochemical, pharmaceutical, aerospace, energy, and food and beverage industries.

Q: What materials are available?

A: Stainless steel, titanium, nickel, and other materials are offered to meet specific application needs.

Q: Can the filters be customized?

A: Yes. We provide full customization for size, shape, aperture, and material to meet your unique requirements.

Contact Us Today

Ready to enhance your filtration processes with our high-quality sintered metal filter discs? Contact us now for a consultation or to place an order:

- Email: sam.young@sintered-metal.com

- Phone/WhatsApp: +8615877694221

_1742364652633.webp)