Sintered Metal Powder Discs

Cleanable

Available Sizes:

Outer Diameter: 10-300mm

Thickness: 1-3mm

Micron Rating: 0.22-100um

- Product Description

High-Performance Filtration Solutions for Industrial Applications

Sintered Metal Powder Discs represent a high-performance filtration solution trusted across critical sectors including aerospace, medical technology, energy, and chemical processing. Manufactured from premium materials such as stainless steel, titanium, and nickel, they maintain outstanding stability and efficiency even in extreme conditions involving elevated temperatures, high pressures, and corrosive media. At [Shaanxi Filture New Material Co., Ltd.], we specialize in delivering tailored filtration components engineered to match your exact application requirements, ensuring long-lasting reliability, superior durability, and optimized operational performance.

Technical Specifications

| Parameter | Value |

|---|---|

| Materials | Stainless Steel, Titanium, Nickel, etc. |

| Pore Size Range | 1 μm - 200 μm |

| Filtration Efficiency | 99% or higher |

| Operating Temperature | Up to 900°C |

| Operating Pressure | Up to 200 bar |

| Disc Thickness | 0.5 mm - 10 mm |

| Diameter | Custom sizes available (from 10 mm to 500 mm) |

| Application | Oil & gas, aerospace, chemical, food, pharmaceuticals |

|  |  |  |

|  |  |  |

Key Features

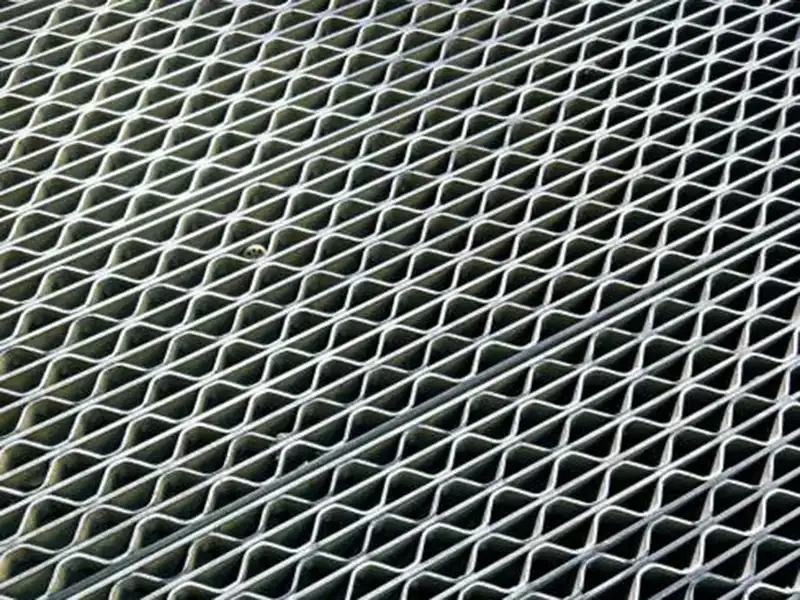

High Porosity for Efficient Filtration

With their highly porous structure, these components deliver superior filtration efficiency while ensuring smooth and consistent flow rates, making them an excellent choice for precision filtration applications across a wide range of industries.Durability and Reliability

These discs are resistant to wear and tear, offering superior mechanical strength and long-lasting performance. Their robustness ensures minimal maintenance and downtime, even under extreme conditions.High Temperature & Pressure Resistance

Our sintered metal discs are designed to withstand high temperatures and pressure, making them perfect for industries like aerospace, oil and gas, and power generation, where reliability in challenging environments is crucial.Corrosion Resistance

Engineered from corrosion-resistant alloys, these filtration elements maintain excellent performance even when exposed to harsh media such as acids, gases, and solvents, thereby offering a much longer service life.

Reusable and Easy to Clean

Thanks to their straightforward yet efficient design, these filters can be cleaned and reused with ease, helping lower operating expenses and ensuring a highly cost-effective filtration solution.

Applications

Sintered metal powder discs are versatile and can be used across a range of industries:

- Energy Sector: Essential in oil & gas filtration and power generation processes, where high filtration efficiency and reliability are paramount.

- Chemical Industry: Used in catalytic reactions, gas separation, and other processes requiring precise filtration of chemicals and gases.

- Aerospace: Lightweight and durable, they serve in filtration systems for jet engines and other critical components.

- Medical Devices: Sintered metal filters meet stringent regulations, making them ideal for life science applications requiring high-quality filter elements.

- Food and Beverage: Ensuring hygienic and safe filtration, our products are used to separate particles in food and beverage processing.

Manufacturing Process

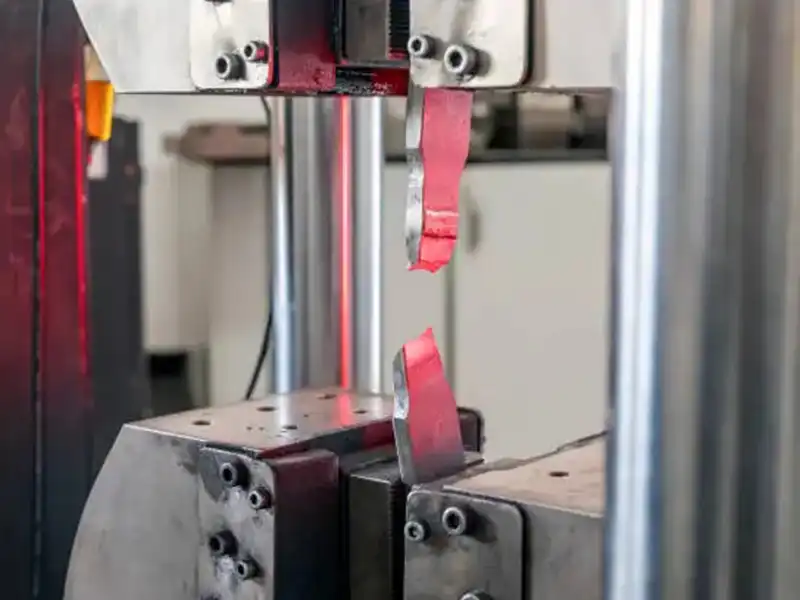

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

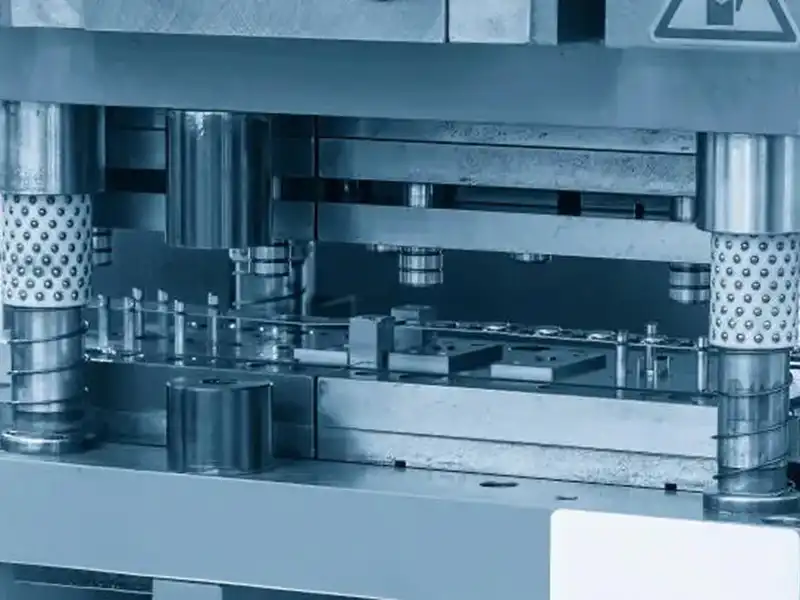

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every industry has unique requirements. That's why we offer a variety of customization options for our sintered metal powder discs:

- Size: Available in different diameters and thicknesses to fit your equipment.

- Material: Choose from stainless steel, titanium, nickel, or other metals based on your specific needs.

- Pore Size: Tailored to provide the perfect balance between filtration efficiency and flow rate.

- Shape: We can create custom shapes to suit your particular applications.

Let us know your requirements, and we’ll provide a solution designed specifically for you.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality always comes first. We enforce stringent control measures throughout the entire production process, from raw material sourcing to final inspection. All products are ISO certified to guarantee compliance with international standards. Through rigorous testing, we ensure that every component delivers consistent reliability even in the most demanding environments, providing customers with complete confidence.

Packaging and Logistics

We pay close attention to packaging to prevent any damage during transportation. Every item is carefully secured and shipped in durable containers to guarantee safe arrival. In addition, our flexible logistics options ensure prompt delivery to international destinations, so your order reaches you efficiently and in excellent condition.

Why Choose Us

With years of experience in the filtration industry, [Shaanxi Filture New Material Co., Ltd.] stands out for its expertise in producing high-quality sintered metal powder discs. We offer:

- Customization options to meet unique requirements

- Proven reliability and high-performance standards

- Competitive pricing without compromising quality

- Flexible supply chain and timely delivery

- Comprehensive customer support, both before and after your purchase

Let us be your trusted partner in filtration solutions.

OEM Services

We offer OEM services tailored to your specific needs. Whether you need custom designs, materials, or sizes, we are equipped to meet your unique specifications. Our flexibility and attention to detail ensure your requirements are met every time.

Frequently Asked Questions (FAQs)

1. What materials are used in your filtration components?

We utilize a range of high-performance metals such as stainless steel, titanium, and nickel to address diverse industrial applications.

2. Which industries benefit from these products?

They are extensively applied in aerospace, energy, chemical processing, medical technology, as well as the food and beverage sector.

3. Do you offer customized options?

Yes. We can tailor size, material selection, pore size, and shape to meet your exact specifications.

Contact Us

For more information or to inquire, please contact us at:

- Email: sam.young@sintered-metal.com

- Phone/Whatsapp: +8615877694221

We look forward to providing you with high-quality filtration solutions!

_1742364652633.webp)