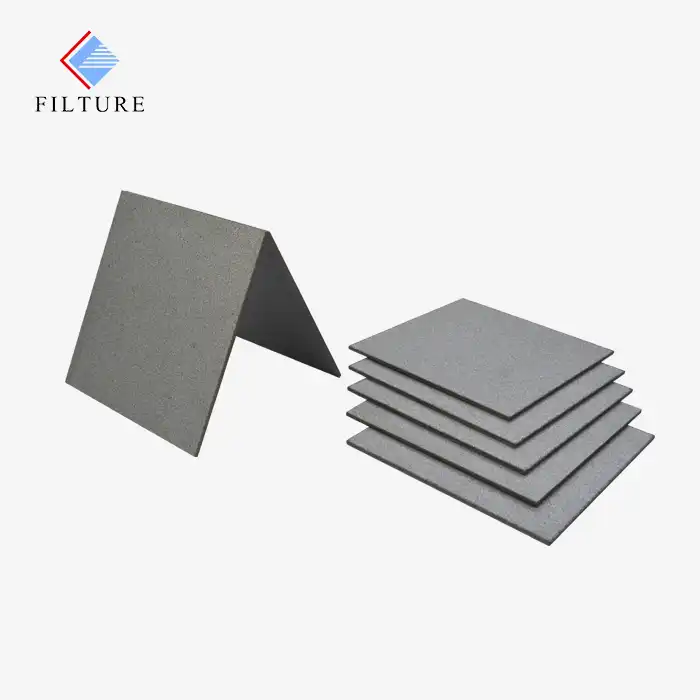

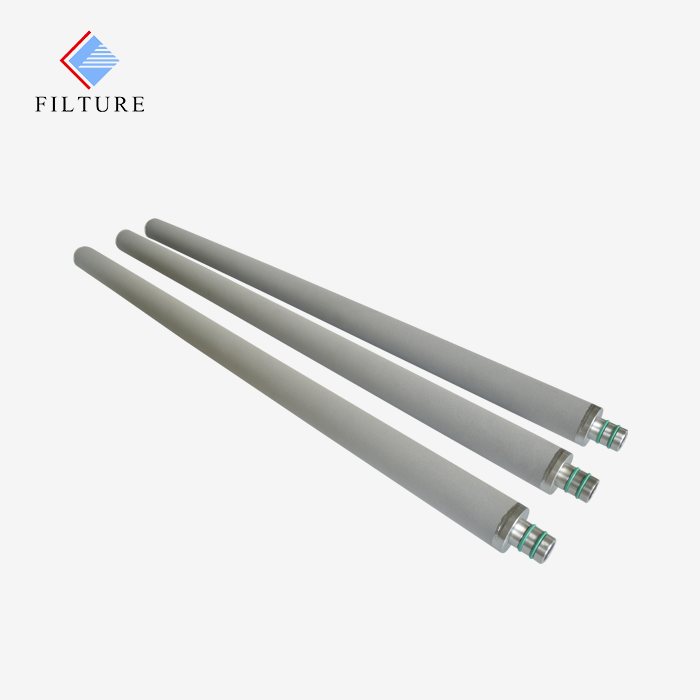

Metal Sintered Filter Sheet

Available Sizes:

Length: Customized

Width: Customized

Micron Rating: 0.22-100um

- Product Description

Metal Sintered Filter Sheet: The Ultimate Solution for High-Efficiency Filtration

Metal sintered filter sheets are engineered for the most demanding industrial applications, offering exceptional filtration efficiency, high durability, and resilience in extreme environments. Designed to withstand high temperatures, pressure, and corrosive conditions, these filters ensure optimal performance, making them a top choice for industries like energy, chemicals, pharmaceuticals, and aerospace. Whether you need to separate fine particles, purify gases, or filter liquids, our product provide superior solutions that guarantee long-lasting reliability and minimal maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Materials | Stainless Steel, Titanium, Nickel, Alloyed Metals |

| Pore Size Range | 0.5 µm – 100 µm |

| Filtration Efficiency | Up to 99.9% |

| Operating Temperature | -200°C to +800°C |

| Operating Pressure | Up to 100 bar |

| Porosity | High porosity for optimal flow and filtration |

| Thickness | 1 mm – 5 mm |

| Surface Finish | Smooth, cleanable surface for ease of maintenance |

| Certifications | ISO 9001, CE, FDA, and other industry-specific certifications |

|  |  |  |

Key Features

- High Temperature Resistance: Our metal sintered filters are designed to perform under high-temperature conditions, making them ideal for use in industries like oil and gas, power generation, and aerospace.

- Corrosion Resistance: These filters can withstand corrosive chemicals, ensuring longevity in aggressive environments like petrochemical and pharmaceutical industries.

- Structural Stability: The sintering process results in filters with exceptional mechanical strength, providing consistent performance even in the harshest conditions.

- Durability and Reusability: With a robust structure, these filters offer high durability and can be cleaned and reused multiple times, reducing maintenance costs.

- Easy to Clean: The smooth surface ensures easy cleaning, which reduces downtime and operational costs.

Applications of Metal Sintered Filter Sheets

- Petrochemical Industry: Ideal for filtration in oil and gas systems, ensuring clean, filtered materials for various processes.

- Pharmaceutical Manufacturing: Critical for ensuring the purity and safety of drugs and medical devices, especially in high-precision applications.

- Food and Beverage Industry: Used in the filtration of oils, juices, and other consumables, maintaining product quality and safety.

- Aerospace: Essential for lightweight, high-strength filtration systems used in aircraft engines and space technology.

- Gas Filtration: Effectively filters gases in industrial settings, offering both fine and coarse filtration solutions.

- Water and Wastewater Treatment: Ensures the removal of fine particulates from water systems.

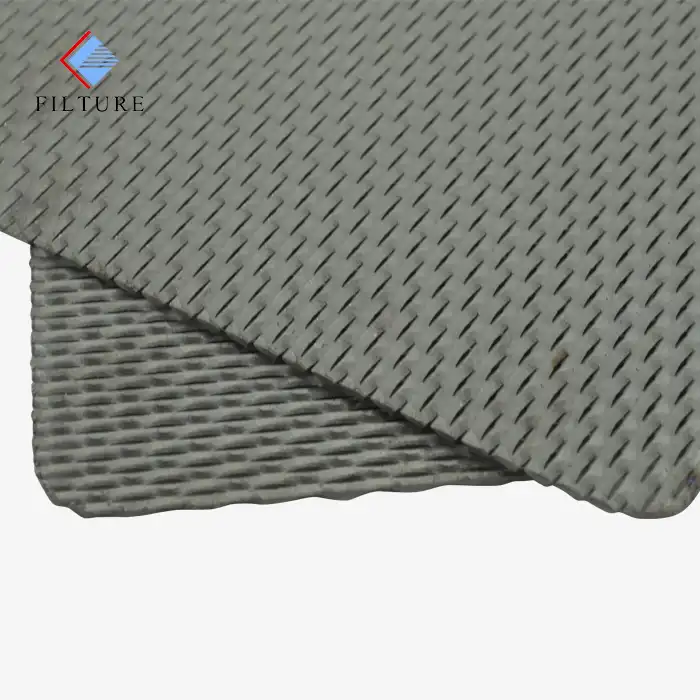

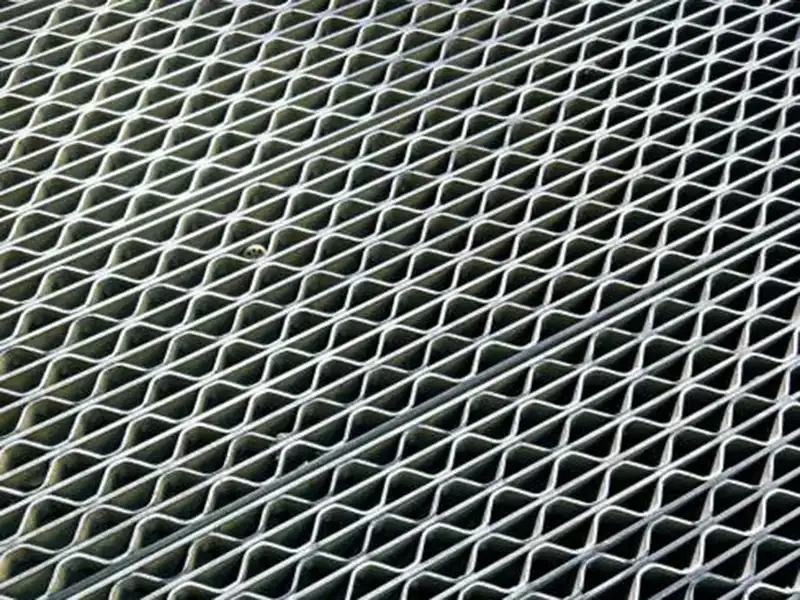

Manufacturing Process

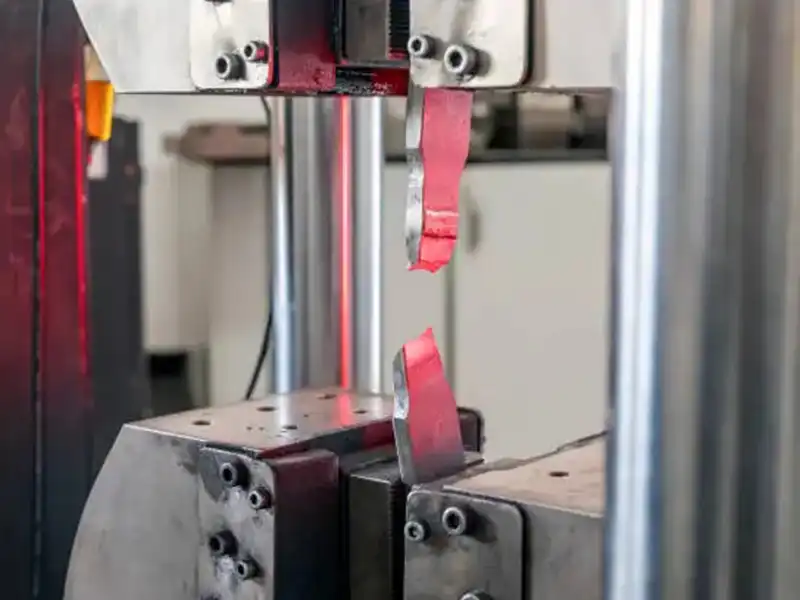

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

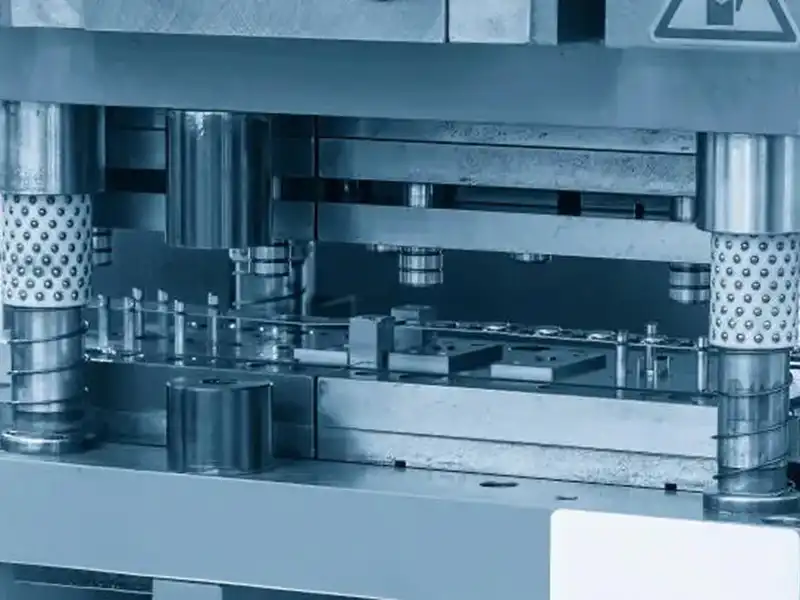

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every customer has unique requirements. That’s why we offer tailored sintered metal filters designed to meet your exact specifications. Whether it’s the material, pore size, thickness, or shape, our flexible production capabilities allow us to create filters optimized for your specific operational needs.

Material: Choose from a variety of metals, including stainless steel, titanium, or nickel, according to your application.

Pore Size & Porosity: Our filters are available in a wide range of pore sizes to ensure precise separation and filtration.

Shape & Size: Custom shapes and dimensions can be produced to fit your equipment or operational conditions perfectly.

Quality Assurance

We maintain strict quality control throughout production. Each sintered metal filter is thoroughly inspected and tested to ensure it meets industry standards and performs reliably under demanding conditions. Our products are certified with international quality standards such as ISO 9001, CE, and FDA, giving you confidence in their consistency and performance.

Packaging and Logistics

Careful packaging protects every filter during shipping. Each unit is securely packed and clearly labeled for easy identification. Our efficient logistics network ensures prompt delivery across North America, Europe, Asia-Pacific, and the Middle East.

Customer Support

Customer satisfaction is our priority. Our technical team provides guidance on product selection, installation, and maintenance. We also offer detailed advice on proper usage to ensure optimal performance and a long service life.

For inquiries or assistance, contact us at:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: +8615877694221

Why Choose Us?

With over 20 years of experience, we are a trusted provider of high-performance sintered metal filters for global industries. Our technical expertise, rigorous quality control, and dedication to customer satisfaction set us apart. We deliver innovative, customized solutions focused on reliability, performance, and cost-effectiveness.

OEM Services

We offer OEM solutions to produce filters designed specifically for your application, including custom material, size, shape, and pore structures. Whether you need a specialized design or advanced filtration solution, our team is ready to help.

FAQ

What is the lifespan of a sintered metal filter?

Our filters are built for durability and can last for many years with proper maintenance. Cleaning and reuse can further extend their service life.How do I select the right pore size?

Our experts can help you choose the optimal size based on your filtration requirements. Contact us for a personalized consultation.Are samples available?

Yes, we provide samples for testing and evaluation. Please reach out to request one.

Contact Details

For more information or to place an order, please contact us directly at:

Email: sam.young@sintered-metal.com

Tel/Whatsapp: +8615877694221

_1742364652633.webp)