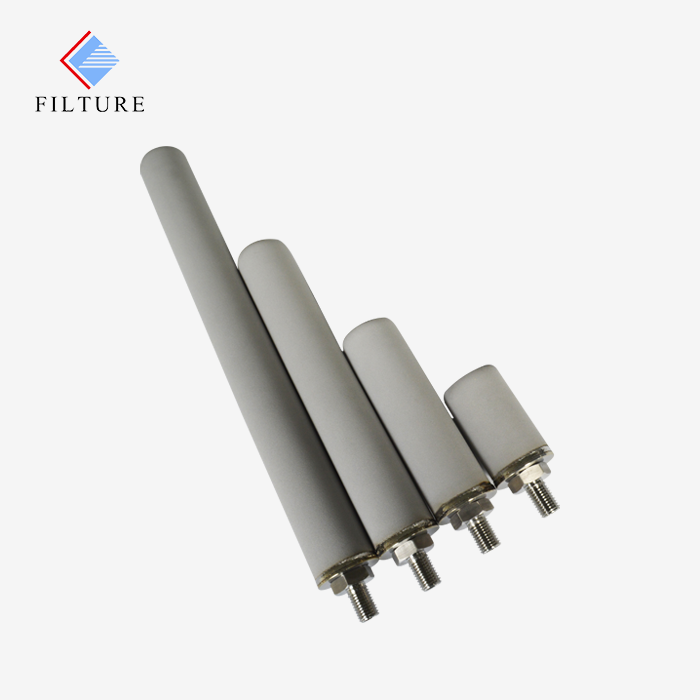

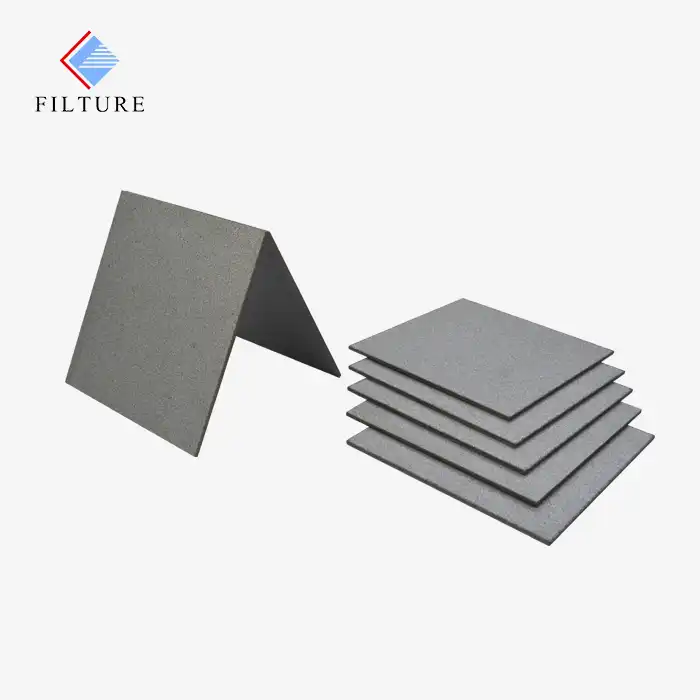

Sintered Metal Plate

Available Sizes:

Length: Customized

Width: Customized

Micron Rating: 0.22-100um

- Product Description

Sintered Metal Plate: High-Performance Filtration Solutions for Extreme Environments

Product Introduction

The Sintered Metal Plate is engineered as a reliable filtration solution for the most challenging industrial environments. With outstanding resistance to high temperatures, excellent corrosion protection, and exceptional structural stability, it performs seamlessly under extreme conditions such as elevated pressure and chemically aggressive atmospheres. Widely used across petrochemical, medical, and aerospace industries, this advanced material delivers both efficiency and long-lasting durability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Options | Stainless steel, titanium, nickel, and more |

| Pore Size Range | 0.1 – 200 microns |

| Filtration Efficiency | Up to 99.99% |

| Operating Temperature | −96°C to 650°C |

| Pressure Tolerance | Up to 10 MPa |

| Dimensions | Customizable |

|  |  |  |

Product Features

High Porosity: Ensures excellent permeability and efficient filtration.

Durability: Resistant to wear and tear, even in abrasive environments.

Corrosion Resistance: Suitable for acidic, alkaline, and other harsh chemical settings.

Easy Maintenance: Cleanable and reusable for reduced operational costs.

Customizable Design: Tailored to your specific filtration or breathability requirements.

Applications

The sintered metal plate is a cornerstone in multiple industries. Key applications include:

Petrochemical Industry: Filtration of gases, liquids, and chemicals under high-pressure conditions.

Pharmaceuticals: Sterile filtration in manufacturing processes.

Food & Beverage: Ensuring product purity in liquid and gas filtration.

Aerospace: Lightweight, high-strength components for filtration and ventilation.

Energy Sector: Reliable solutions for power generation and gas separation.

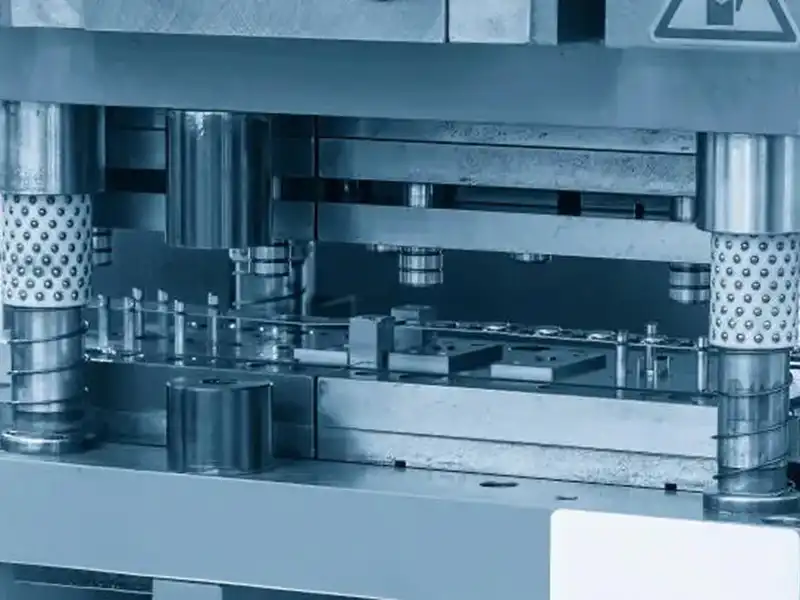

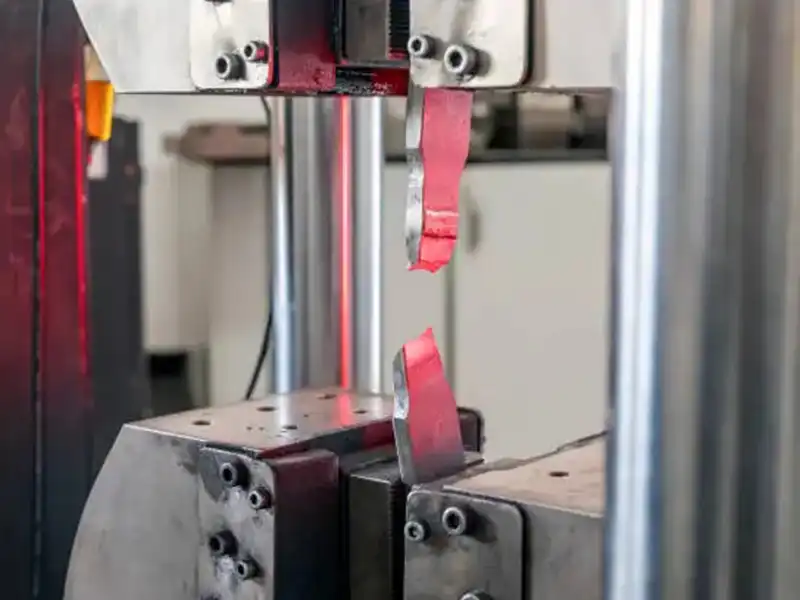

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

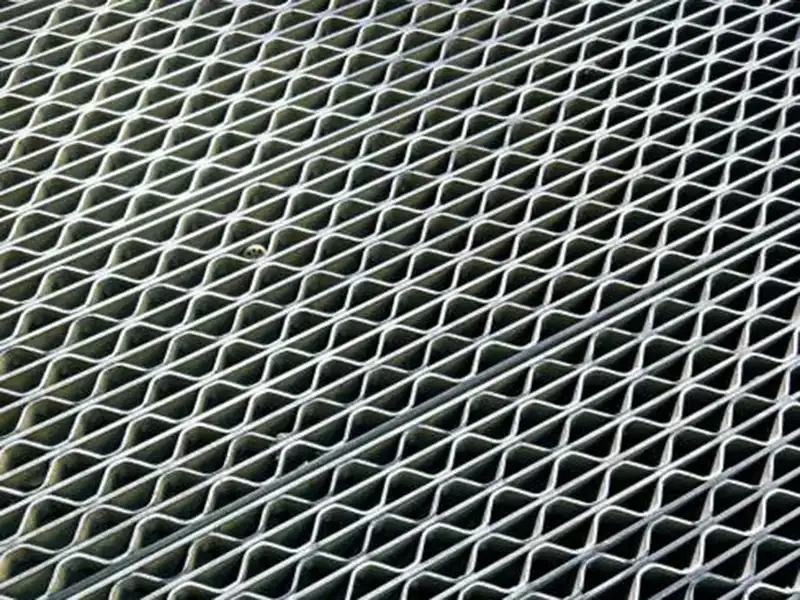

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We deliver tailored filtration solutions designed to match your exact requirements:

Materials: Stainless steel, titanium, nickel, and specialty alloys.

Dimensions: Fully customizable in size, thickness, and shape.

Pore Sizes: Adjustable to achieve precise permeability and filtration accuracy.

Other Features: Options for special coatings, multi-layer construction, or reinforced designs.

Quality Assurance

Our products are manufactured under a strict quality management system and undergo extensive testing for durability and consistency. With certifications such as ISO and CE, every Sintered Metal Plate is guaranteed to meet international standards and deliver reliable performance even in demanding environments.

Packaging and Logistics

To protect your order, each plate is securely packaged to prevent damage during transportation. We provide flexible logistics solutions to ensure timely delivery worldwide, with standard lead times ranging from 7 to 21 days depending on volume and destination.

Why Choose Us

Proven Experience: Decades of expertise in advanced filtration solutions.

Technical Innovation: Strong R&D capability for customized applications.

Global Service: Trusted by clients across Europe, North America, Asia-Pacific, and the Middle East.

Flexible Manufacturing: Tailored designs to meet unique industry needs.

Dependable Supply: Reliable production and fast logistics ensure on-time delivery.

OEM Services

We specialize in OEM production, offering customized Sintered Metal Plate solutions engineered to your specific material, design, and performance requirements. Our team collaborates closely with you from concept to delivery.

FAQ

Q1: What is the service life of your filtration plates?

A: With proper care, they can deliver stable performance for many years, even in harsh environments.

Q2: Are food-grade options available?

A: Yes, we provide FDA-compliant materials suitable for food and beverage processing.

Q3: Do you offer technical guidance?

A: Absolutely. Our engineers provide full support for product selection, maintenance, and system integration.

Contact Details

For inquiries and orders, reach out to us:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: 8615877694221

_1742364652633.webp)