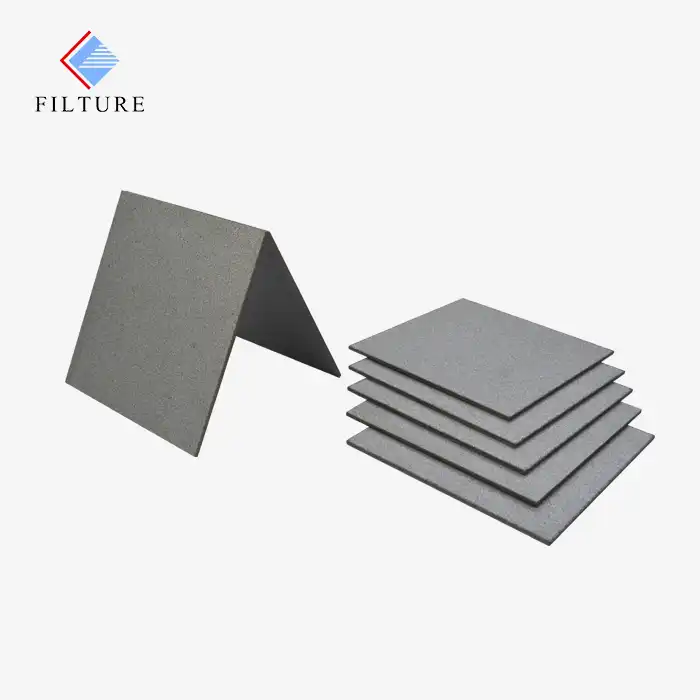

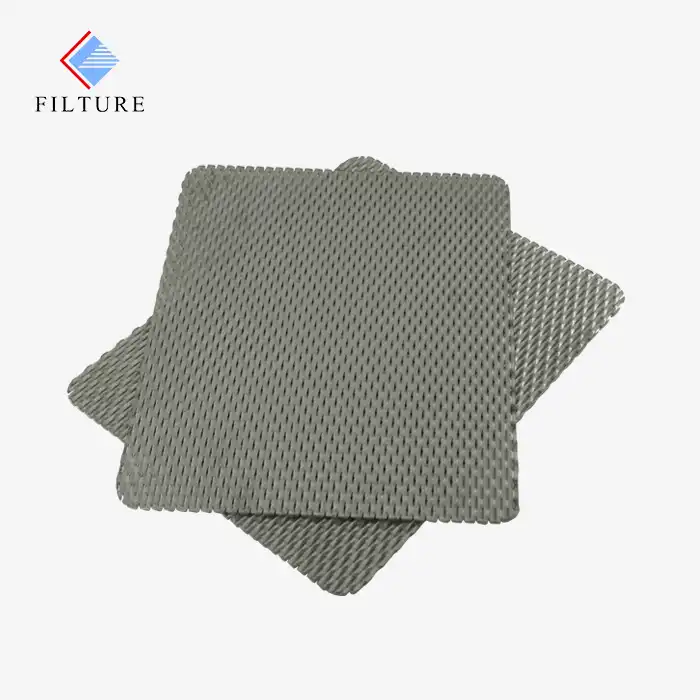

Sintered Metal Filter Sheet

Available Sizes:

Length: Customized

Width: Customized

Micron Rating: 0.22-100um

- Product Description

Sintered Metal Filter Sheet: High-Performance Filtration Solutions

Experience unmatched efficiency and durability with our advanced filtration solution. Engineered to perform under extreme conditions, it offers excellent resistance to high temperatures, superior protection against corrosion, and outstanding structural stability. This makes it the ideal choice for challenging industrial applications. Whether you need precise filtration or dependable performance in harsh environments, our Sintered Metal Filter Sheet is designed to exceed expectations.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Options | Stainless Steel, Titanium, Nickel, Alloys |

| Pore Size Range | 0.1 µm – 100 µm |

| Filtration Efficiency | Up to 99.99% |

| Operating Temperature | -200°C to 1000°C |

| Maximum Pressure | Up to 30 MPa |

| Thickness | 0.5 mm – 5 mm |

| Shape Options | Sheets, Discs, Custom Shapes |

|  |  |  |

Key Features

High Porosity: Facilitates excellent airflow and filtration efficiency.

Durability: Withstands extreme temperatures, pressures, and corrosive environments.

Easy Maintenance: Reusable and easy to clean for long-term cost savings.

Structural Stability: Retains performance in high-stress applications.

Versatility: Available in customizable sizes, shapes, and materials.

Applications

Our sintered metal filter sheets find extensive use across diverse industries:

Petrochemical Industry: Ensures efficient separation and purification of hydrocarbons.

Pharmaceutical Manufacturing: Supports sterile filtration processes.

Food and Beverage: Enables fine filtration in processing and production.

Aerospace Sector: Provides high-strength, lightweight solutions for gas filtration.

Energy and Chemical Industry: Ideal for high-temperature and high-pressure operations.

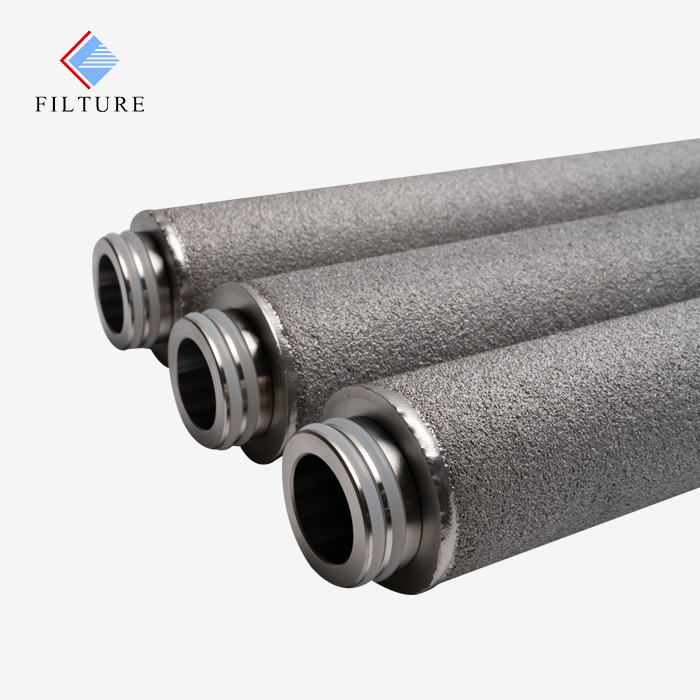

Manufacturing Process

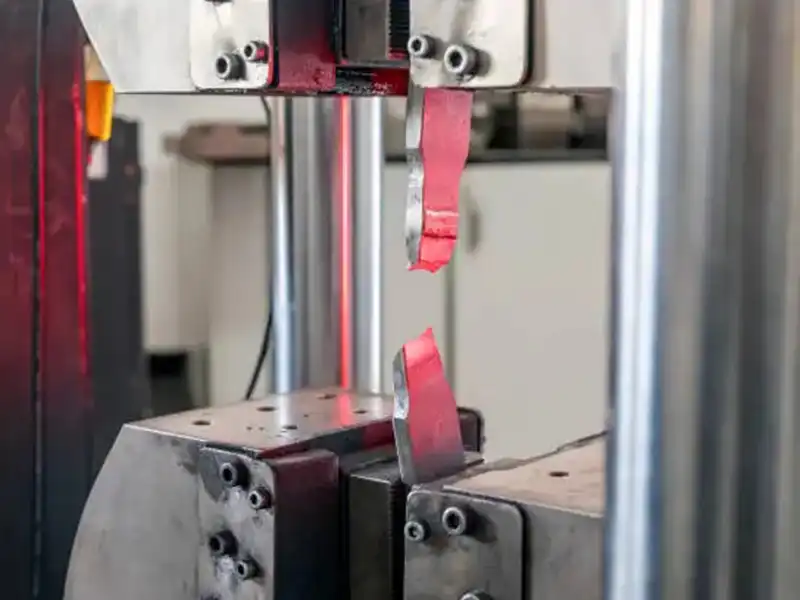

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

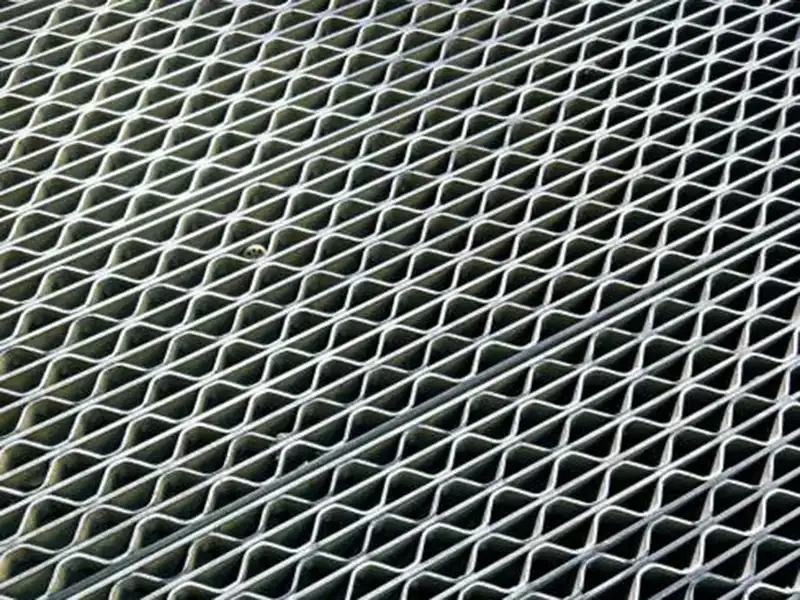

Metal Mesh

Titanium and Stainless Steel metal fibers

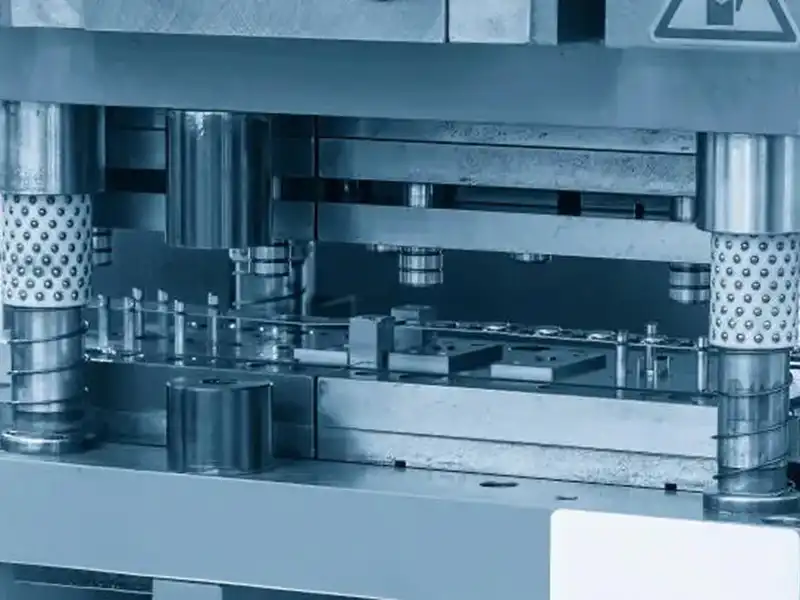

Molding process

Pressing

High temperature sintering

Welding

Customization Options

Tailor your Sintered Metal Filter Sheet solutions to meet precise operational needs:

Material Choices: Stainless steel, titanium, nickel, and custom alloys.

Dimensions: Wide range of sizes, shapes, and thicknesses.

Pore Sizes: Adjustable options for accurate filtration performance.

Quality Assurance

We follow strict quality management standards to guarantee consistent excellence:

Certifications: ISO, CE, FDA compliance.

Testing: Rigorous performance and durability evaluation.

Inspection: Comprehensive checks for flawless delivery.

Packaging and Logistics

Every Sintered Metal Filter Sheet is carefully packaged to avoid damage during transportation. With efficient international shipping services, we ensure timely and secure delivery.

Why Choose Us?

Industry Expertise: Years of experience in advanced filtration technology.

Cutting-Edge Manufacturing: Precision processes for superior performance.

Global Network: Serving Europe, North America, Asia-Pacific, and the Middle East.

Custom Solutions: Flexible production to fit your application.

Trusted Partnerships: Reliable supplier for leading industries.

OEM Services

We provide tailored OEM manufacturing, working closely with clients from design through delivery to guarantee optimal results.

FAQ

Q1: What materials are available?

We offer stainless steel, titanium, nickel, and specialized alloys.

Q2: Can they handle high pressure?

Yes, our filter sheets are engineered to withstand up to 30 MPa.

Q3: Do you provide custom dimensions?

Absolutely — we specialize in customized shapes and sizes.

Q4: How can they be cleaned?

Cleaning methods include backflushing, ultrasonic cleaning, or chemical treatment.

Contact Us

For inquiries and orders, reach out to us at:

Email: sam.young@sintered-metal.com

Tel/WhatsApp: +8615877694221

Experience the difference with our high-quality sintered metal filter sheets. Contact us today!

VIEW MORESintered Metal Filter Plate

VIEW MORESintered Metal Filter Plate VIEW MOREMetal Sintered Filter Sheet

VIEW MOREMetal Sintered Filter Sheet VIEW MORETitanium Filtration Mesh Panels

VIEW MORETitanium Filtration Mesh Panels VIEW MORE316l Stainless Steel Sintered Porous Metal Filter Element

VIEW MORE316l Stainless Steel Sintered Porous Metal Filter Element VIEW MORESintered Stainless Steel Filter Elements

VIEW MORESintered Stainless Steel Filter Elements VIEW MORESintered Metal Plate

VIEW MORESintered Metal Plate VIEW MORESintered Metal Sheet

VIEW MORESintered Metal Sheet VIEW MOREMetal Sintered Filter Plate

VIEW MOREMetal Sintered Filter Plate

_1742364652633.webp)