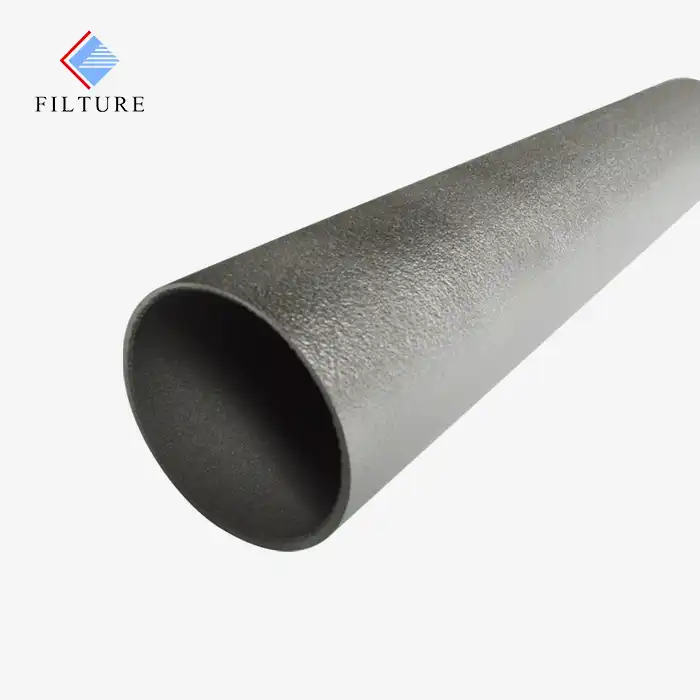

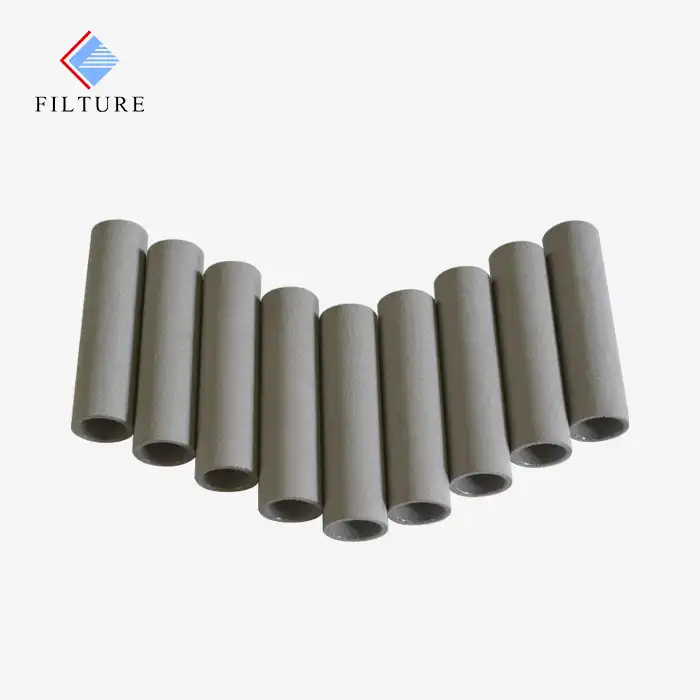

Sintered Metal Tube

Absolute Rate

Cleanable

Available Sizes:

Outer Diameter: Customized

Inner Diameter: Customized

Micron Rating: 0.22-100um

- Product Description

High-Performance Filtration for Demanding Applications

Welcome to the world of Sintered Metal Tubes, where precision engineering meets outstanding performance. These advanced filtration elements are engineered to endure harsh conditions including high temperatures, extreme pressures, and corrosive environments. Serving industries such as energy, chemical, pharmaceutical, and aerospace, they deliver exceptional durability, reliable operation, and superior filtration efficiency.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 5 μm to 100 μm |

| Filtration Efficiency | 99.9% |

| Operating Temperature | Up to 600°C (1,112°F) |

| Operating Pressure | Up to 200 bar |

| Dimensions | Custom sizes available |

| Corrosion Resistance | Excellent in harsh environments |

|  |  |  |

Key Features

High Porosity: The optimized porous structure enhances filtration efficiency, effectively capturing even the finest particles.

Durability: Built for longevity, they maintain stable performance under extreme temperatures, high pressures, and corrosive media.

Easy Cleaning & Reuse: Their practical design allows simple cleaning and repeated use, offering both cost-effectiveness and sustainability.

Corrosion & Pressure Resistance: Manufactured from high-grade materials, they provide superior resistance to aggressive chemicals and high-pressure conditions, making them ideal for industries such as petrochemical and aerospace.

Applications

Our Sintered Metal Tubes are highly versatile, serving a wide range of industrial applications:

Petrochemical: Utilized in filtration systems for gases, liquids, and oils under harsh conditions, ensuring precise and reliable separation.

Pharmaceutical: Critical for sterilization, purification, and filtration processes, maintaining product safety and compliance with strict health standards.

Food and Beverage: Applied for fine filtration to guarantee the highest product quality and safety during production.

Gas Filtration: Perfect for clean air applications in industrial systems, efficiently removing dust and particulates to maintain operational performance.

Manufacturing Process

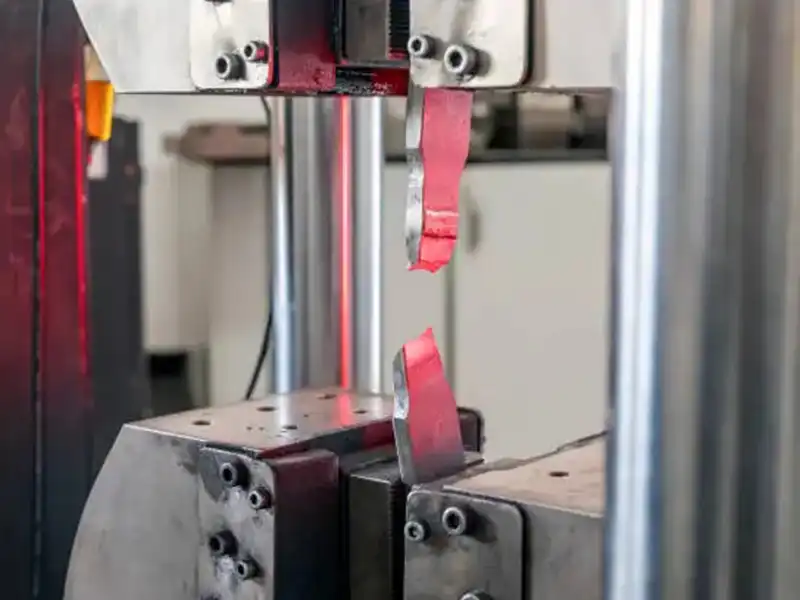

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

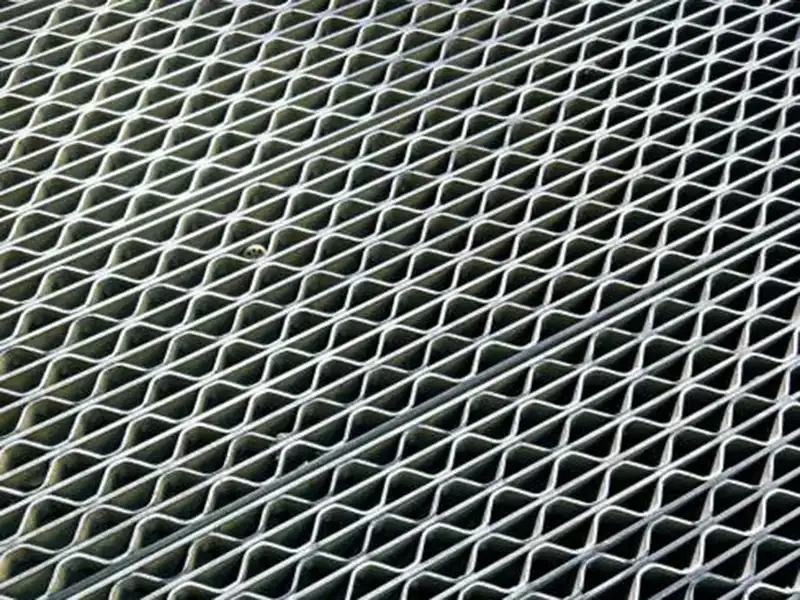

Metal Mesh

Titanium and Stainless Steel metal fibers

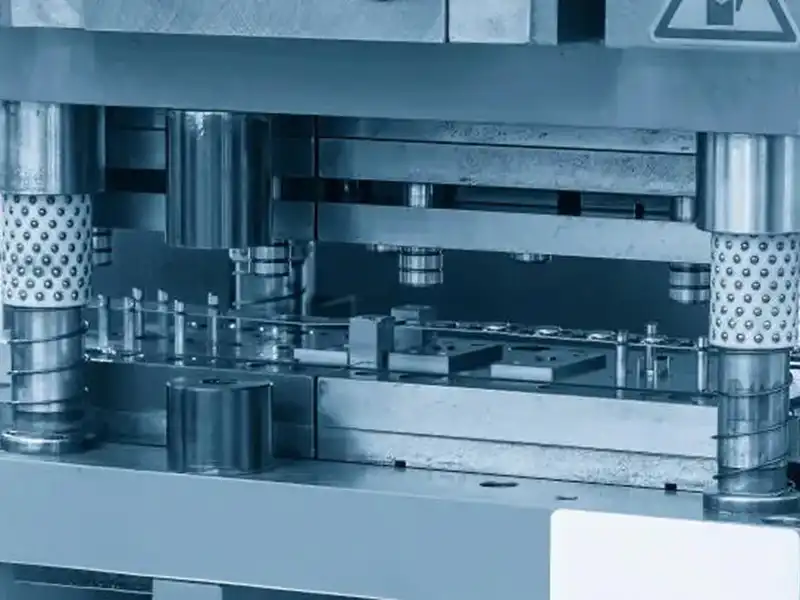

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every industry and application has its own set of requirements.

- Custom sizes and dimensions

- Specific pore sizes and filtration properties

- Material selection (Stainless steel, Titanium, Nickel, etc.)

- Unique shapes and forms to fit your operational needs

Our flexible production capabilities ensure we can meet the most demanding specifications and help you optimize your filtration processes.

Why Choose Us?

With over [XX] years of experience in sintered metal filtration solutions, we have established a reputation for quality, reliability, and customer satisfaction. Our expertise in customized production, commitment to excellence, and efficient delivery systems make us the go-to choice for industrial filtration needs.

OEM Services

We offer comprehensive OEM services, customizing our filtration components to match your exact requirements. Whether you need specific sizes, materials, or unique specifications, our team collaborates closely with you to deliver the perfect solution.

Frequently Asked Questions (FAQs)

Q: Which industries utilize these filtration components?

A: They are widely applied in sectors such as petrochemical, pharmaceutical, food and beverage, aerospace, and energy, thanks to their excellent filtration performance.

Q: Can I customize the size and material?

A: Yes, we provide full customization options to suit your specific requirements.

For more information or to place an order, please contact us today at sam.young@sintered-metal.com or +8615877694221.

VIEW MORESintered Porous Metal Tube

VIEW MORESintered Porous Metal Tube VIEW MOREHigh Quality Stainless Steel Filter Element

VIEW MOREHigh Quality Stainless Steel Filter Element VIEW MOREStainless Steel Filter Element Product

VIEW MOREStainless Steel Filter Element Product VIEW MORESintered Metal Tubes

VIEW MORESintered Metal Tubes VIEW MORESintered Metal Filter Tube

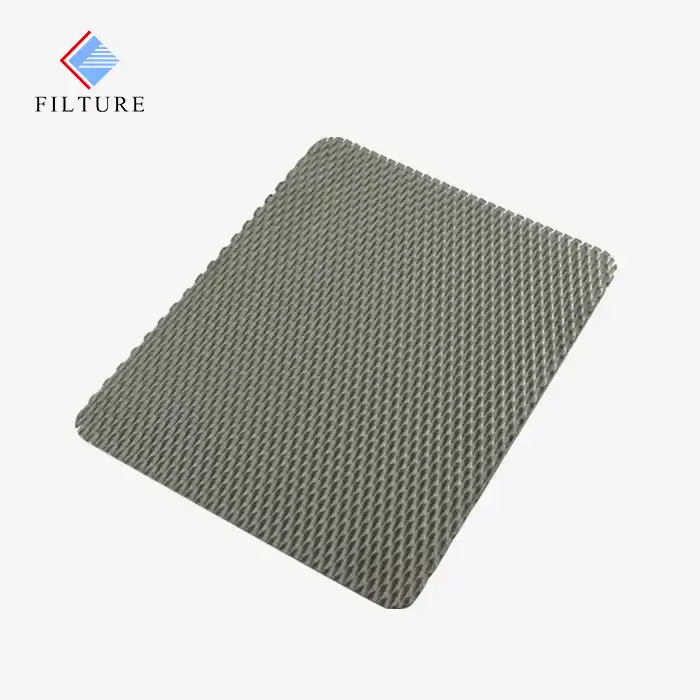

VIEW MORESintered Metal Filter Tube VIEW MORESintered Plate Filter Element

VIEW MORESintered Plate Filter Element VIEW MORESintered Metal Plate

VIEW MORESintered Metal Plate VIEW MORETitanium Expanded Metal Sheets

VIEW MORETitanium Expanded Metal Sheets

_1742364652633.webp)