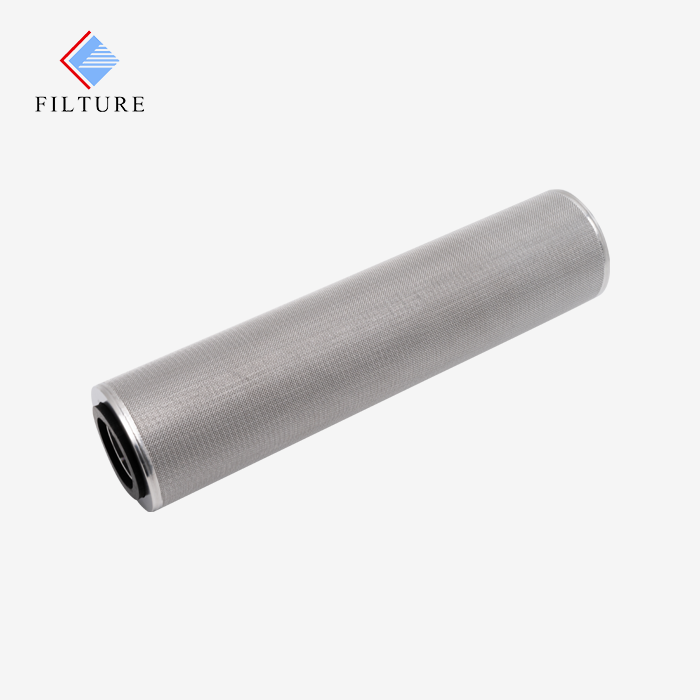

High Quality Stainless Steel Filter Element

Absolute Rate

Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length: 254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: Above 1um

- Product Description

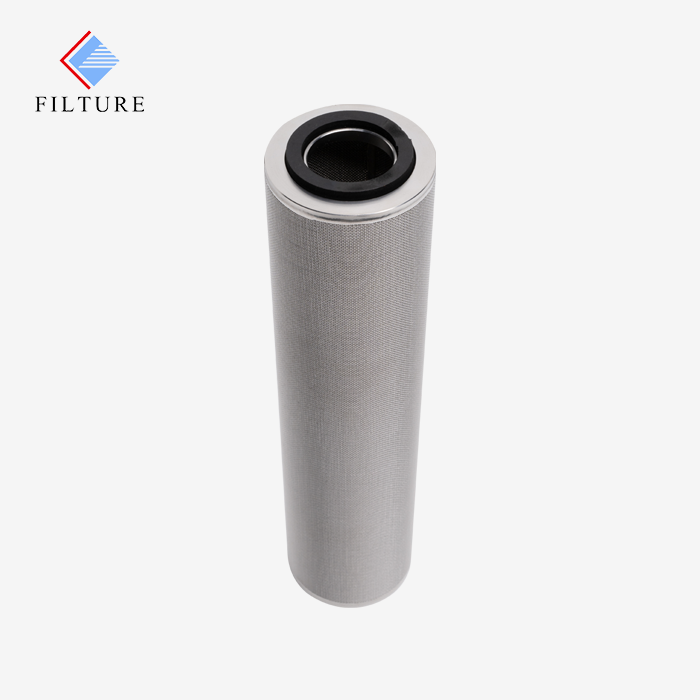

High-Quality Stainless Steel Filter Element: Premium Filtration Solutions for Your Industry Needs

Welcome to Shaanxi Filture New Material Co., Ltd., where we provide high quality stainless steel filter elements that cater to the demands of industries worldwide. Our stainless steel filters are designed for extreme conditions such as high temperatures, high pressures, and corrosive environments, ensuring efficient performance in even the most challenging applications. With superior strength, corrosion resistance, and durability, these filters are perfect for industries like aerospace, energy, chemical, medical, and more.

Technical Specifications

Our high-quality stainless steel filter elements are designed to meet the highest industry standards. Here are the key technical specifications:

| Parameter | Value |

|---|---|

| Material | Stainless Steel (304, 316L) |

| Pore Size Range | 1 µm to 200 µm |

| Filtration Efficiency | 99.99% |

| Operating Temperature | Up to 600°C (for special grades) |

| Operating Pressure | Up to 350 bar |

| Dimensions | Customizable |

| Shape | Cylindrical, Disc, Custom |

| Max. Filtration Flow | 1000 L/min |

These specifications are designed to meet the needs of industries that require filtration elements capable of withstanding extreme conditions while providing highly efficient filtration.

|  |  |  |  |

Key Features

Solidness and Long-Term Reliability:

Our high-quality stainless steel channel components are built for toughness and long-lasting execution. Their capacity to withstand tall temperatures, weights, and destructive situations guarantees a lessening in upkeep costs and expands the life expectancy of your filtration system.

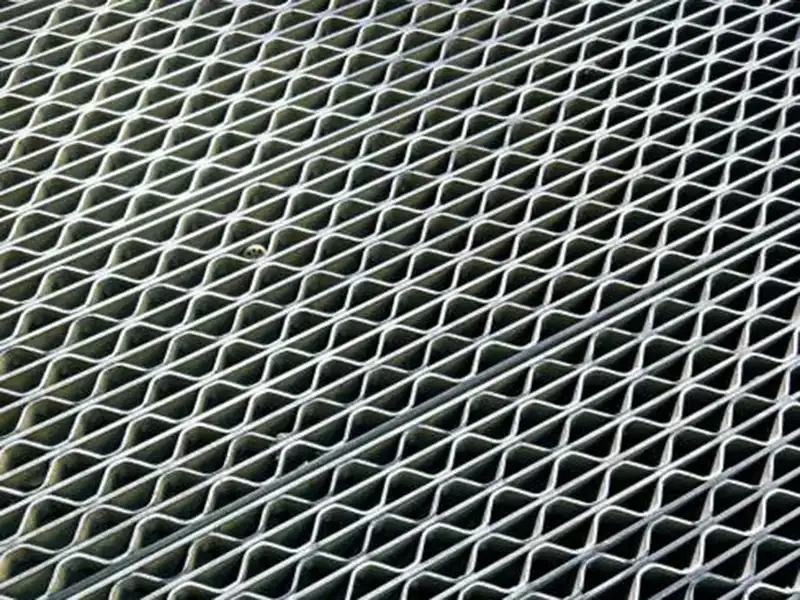

High Porosity and Proficient Filtration:

The interesting sintering prepare utilized to make these channels gives them tall porosity and uniform pore dissemination, guaranteeing that indeed the littlest particles are successfully sifted out. With fabulous filtration productivity, these components give extraordinary partition and purification.

Easy to Clean and Reuse:

Thanks to their strong plan, these stainless steel channels are simple to clean and reuse, making them a cost-effective arrangement for businesses with persistent filtration needs.

Corrosion Resistance:

The stainless steel fabric offers great resistance to erosion, making it appropriate for utilize in businesses that bargain with cruel chemicals and high-pressure conditions.

Applications

Our high quality stainless steel filter elements find use across a wide range of industries and applications. Here are some key sectors that benefit from our filtration solutions:

- Petrochemical Industry: Utilized in filtration of unrefined oil, common gas, and other chemicals.

- Pharmaceutical and Therapeutic: Guarantees sterile filtration for pharmaceutical generation and therapeutic devices.

- Food and Refreshment: Utilized in the decontamination and division of fluids in nourishment processing.

- Gas Filtration: Perfect for utilize in discuss and gas filtration frameworks, guaranteeing clean and breathable air.

- Energy: Fundamental for filtration in control era, oil & gas, and renewable vitality generation.

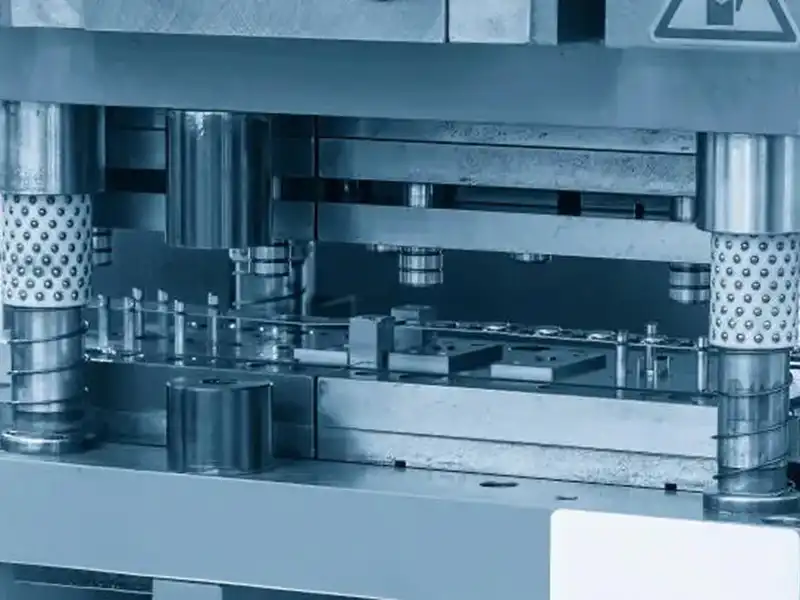

Manufacturing Process

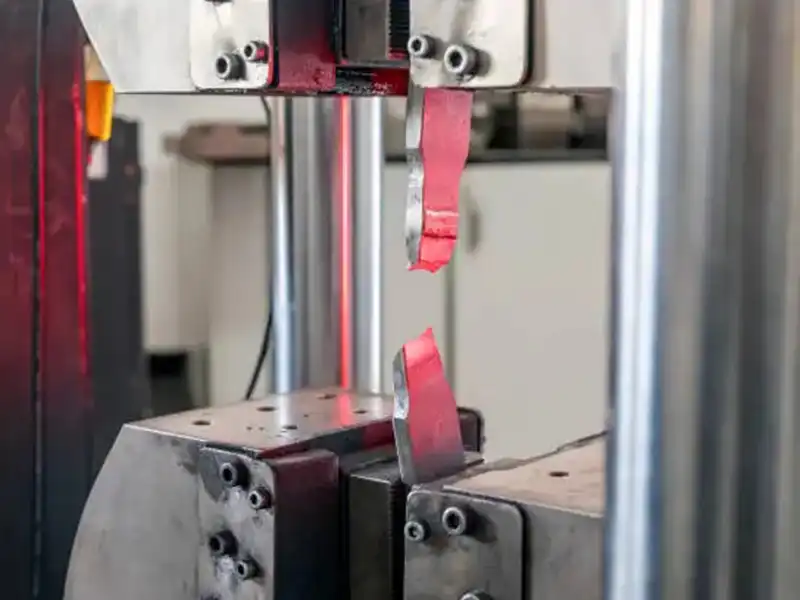

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

At Shaanxi Filture, we know that every industrial application has distinct requirements. That’s why we offer full customization for the High Quality Stainless Steel Filter Element. Customers can select from a wide range of sizes, shapes, and materials, including specialized options for demanding filtration needs. With flexible production capabilities, we deliver tailored solutions that align with your exact specifications.

Quality Assurance

Quality is central to our manufacturing process. Each High Quality Stainless Steel Filter Element is produced under strict quality control protocols and tested rigorously to ensure superior performance. Certified to international standards such as ISO, our products are designed to provide reliable, long-lasting filtration in real-world industrial environments.

Packaging and Logistics

We take special care in packaging to ensure each filter element arrives safely. Protective packaging prevents damage during transport, and with our efficient logistics network, we guarantee timely delivery to customers across the globe.

Customer Support

Our customer-focused approach goes beyond supplying products. We provide comprehensive pre-sales and post-sales services, including technical consultation, troubleshooting, and maintenance guidance. Our expert team is always ready to support your filtration needs.

Contact Us

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +86 158 7769 4221

Why Choose Us?

Industry Expertise: Decades of experience delivering advanced filtration solutions for critical applications.

Customized Solutions: Products tailored to meet your business-specific needs.

Reliable Delivery: A strong supply chain that ensures consistent on-time shipments.

Dedicated Support: Responsive technical and service assistance at every step.

OEM Services

We offer OEM production to meet unique customer requirements. Whether you need a specific size, shape, or material, our team can design and manufacture the High Quality Stainless Steel Filter Element to your precise specifications.

FAQ

Q1: What is the typical lifespan of these filter elements?

A1: With proper maintenance, they are designed to last for several years, even in challenging environments.

Q2: Can I order customized dimensions?

A2: Yes, we provide full customization for size, shape, and material.

Q3: How should I clean and maintain the filters?

A3: They can be easily cleaned and reused. We recommend periodic maintenance based on your system’s operating conditions.

Contact Details

Ready to find out more or place an order? Get in touch with us today!

Email: sam.young@sintered-metal.com

Phone/Whatsapp: +86 158 7769 4221

We look forward to providing you with the best high quality stainless steel filter elements that meet your exact needs. Contact us today to discuss how we can help with your filtration solutions!

VIEW MORESS Sintered Filter Element

VIEW MORESS Sintered Filter Element VIEW MORESintered Titanium Steam Filter Element

VIEW MORESintered Titanium Steam Filter Element VIEW MOREStainless Steel Filter Element

VIEW MOREStainless Steel Filter Element VIEW MOREStainless Steel Mesh Filter Element

VIEW MOREStainless Steel Mesh Filter Element VIEW MOREStainless Steel Sintered Mesh Filter Elements

VIEW MOREStainless Steel Sintered Mesh Filter Elements VIEW MOREStainless Steel Filter Element Product

VIEW MOREStainless Steel Filter Element Product VIEW MOREStainless Steel Filter Element Products

VIEW MOREStainless Steel Filter Element Products VIEW MORESintered Metal Disc

VIEW MORESintered Metal Disc

_1742364652633.webp)