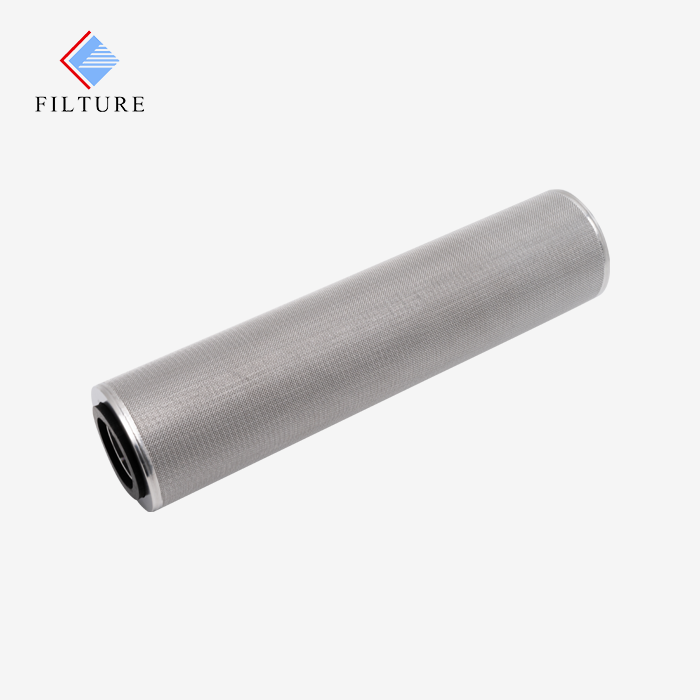

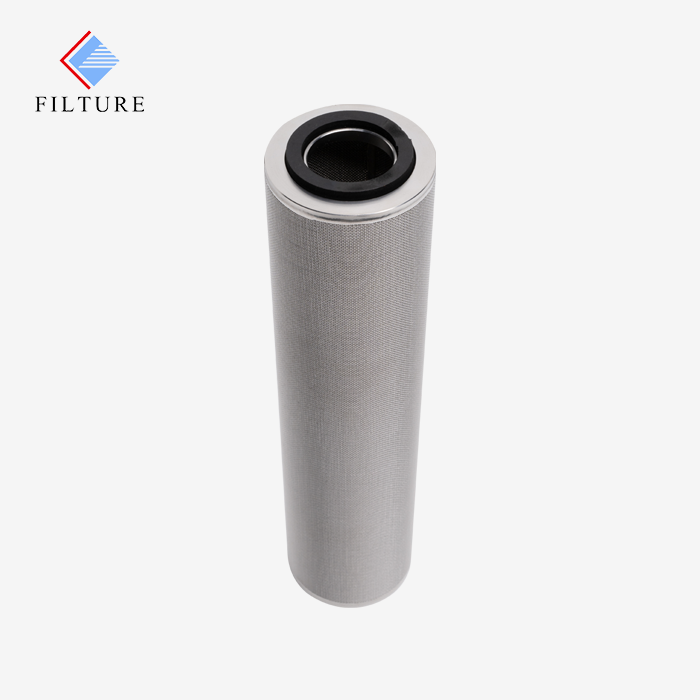

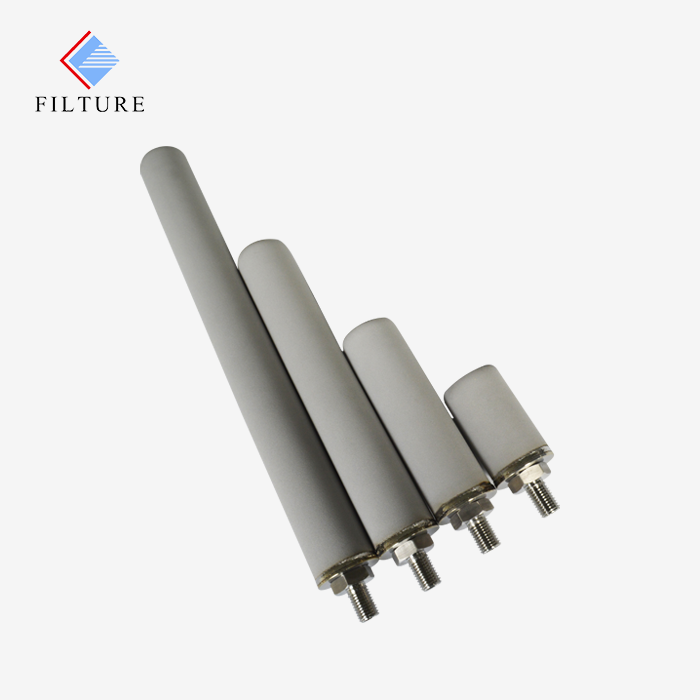

Stainless Steel Mesh Filter Element

Absolute Rate

Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length: 254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: Above 1um

- Product Description

Stainless Steel Mesh Filter Element: High-Quality Filtration Solutions for Demanding Industries

Welcome to Shaanxi Filture New Material Co., Ltd., where we specialize in providing top-tier stainless steel mesh filter elements designed to meet the rigorous demands of industries around the world. Whether you're in aerospace, petrochemical, energy, or medical fields, our filter elements offer superior performance in extreme conditions, such as high temperatures, high pressures, and corrosive environments. Let us provide the filtration solutions you need for your operations.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.5 µm to 500 µm |

| Filtration Efficiency | Up to 99.99% |

| Operating Temperature | Up to 800°C (varies by material) |

| Operating Pressure | Up to 150 bar |

| Shape | Customizable (Round, Square, etc.) |

| Max Flow Rate | Depends on size and application |

| Standard Certification | ISO 9001, CE, FDA |

|  |  |  |  |

Key Features

Our products are engineered for optimal performance, offering numerous advantages that make them the ideal choice for industries that require precision and reliability. Key features include:

- Tall Porosity: Guarantees effective filtration indeed for fine particles whereas keeping up tall stream rates.

- Durability: Outlined to withstand unforgiving working situations, advertising long-term reliability.

- Easy to Clean and Reuse: Not at all like conventional channels, these work components can be cleaned and reused different times, diminishing operational costs.

- Corrosion Resistance: Idealize for utilize in chemical, pharmaceutical, and nourishment handling businesses where presentation to forceful chemicals is common.

- Temperature and Weight Resistance: Competent of withstanding extraordinary temperatures and weights, these channels guarantee reliable execution in challenging conditions.

Applications

Our stainless steel mesh filter elements are ideal for a wide range of applications across various industries, including:

- Petrochemical Industry: Utilized in refining forms, filtration of oils, gasses, and fuels.

- Pharmaceutical Industry: Basic for sterile filtration in medicate generation and therapeutic devices.

- Food and Refreshment: Guarantees security and quality in the filtration of refreshments, oils, and other nourishment products.

- Aerospace: Lightweight and solid, these channel components are utilized in fly motors and other aviation applications.

- Gas Filtration: Basic for high-efficiency filtration of gasses, counting for mechanical and natural purposes.

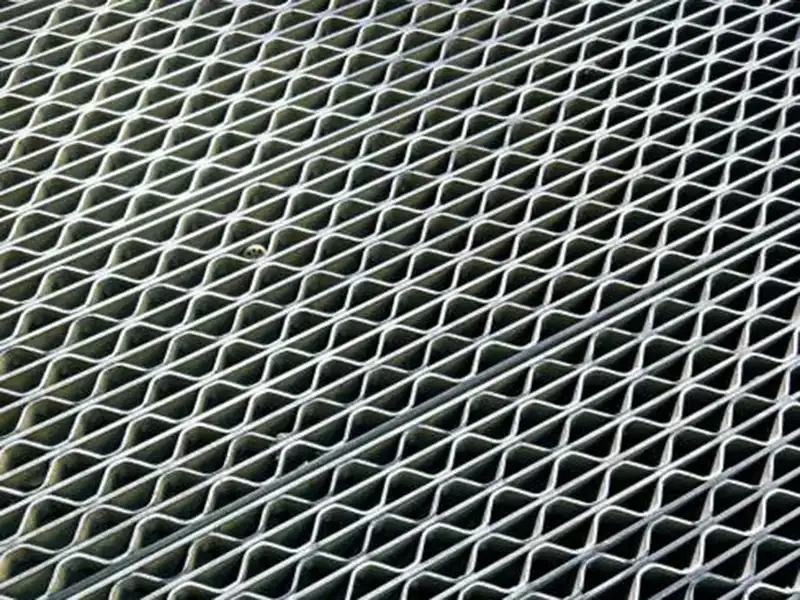

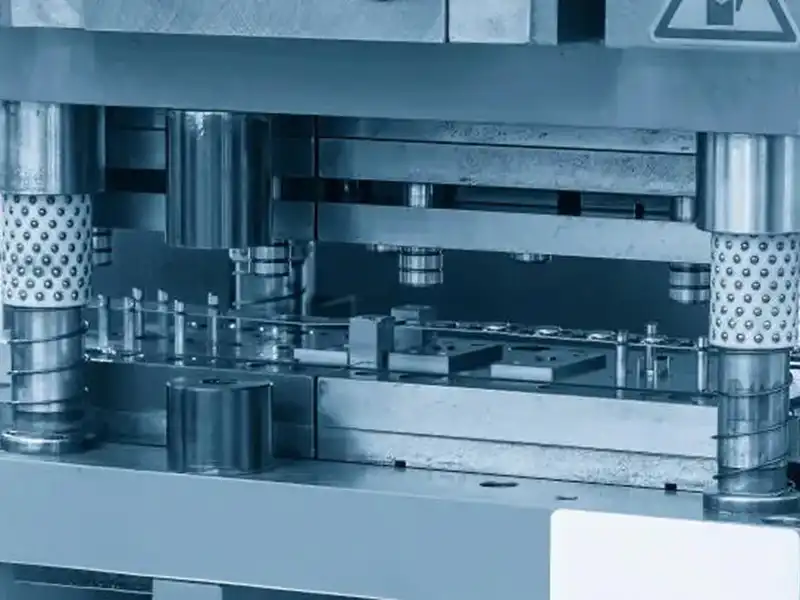

Manufacturing Process

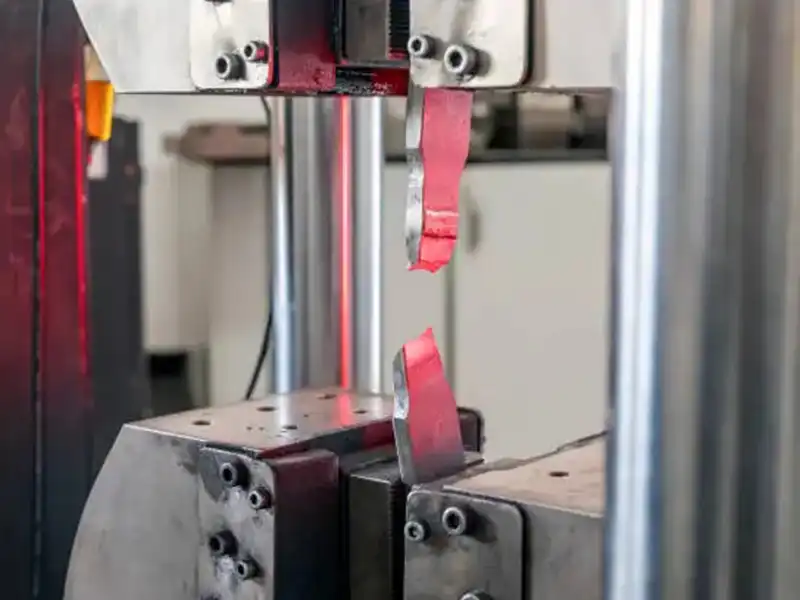

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every customer has unique requirements, which is why we provide extensive customization for the Stainless Steel Mesh Filter Element. Whether it’s the size, aperture, shape, or choice of material (such as titanium or nickel), we collaborate closely with clients to deliver tailored solutions that precisely match their applications. With flexible production capabilities, we ensure customized elements are manufactured quickly and efficiently.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality is our top priority. Each filter element undergoes strict inspection and testing to guarantee compliance with global standards. Our processes align with ISO 9001, CE, and FDA certifications, ensuring every product meets international quality and safety requirements.

Packaging and Logistics

To ensure your order arrives in perfect condition, all products are securely packaged with protective materials to avoid damage during transport. We provide reliable global shipping solutions, ensuring safe and timely delivery to customers worldwide.

Customer Support

Our dedicated support team is available to assist at every stage—from initial consultation to after-sales service. We offer technical guidance, installation assistance, and maintenance advice, helping you maximize the performance of your Stainless Steel Mesh Filter Element.

Why Choose Us?

Industry Expertise: Years of experience in filtration solutions for diverse sectors.

Customization: Tailor-made filter elements designed to fit exact operational requirements.

Reliable Delivery: Strong supply chain ensuring timely global shipments.

Comprehensive Support: Professional guidance and customer-focused service at all times.

OEM Services

We specialize in OEM manufacturing, enabling customers to request specific designs, dimensions, or materials. This ensures the Stainless Steel Mesh Filter Element perfectly aligns with your technical and branding needs.

FAQ

1. What materials are available?

We manufacture filter elements from stainless steel, titanium, and nickel, selected based on your application requirements.

2. What is the maximum operating temperature?

Depending on material choice, these filter elements can operate at temperatures up to 800°C.

3. Can the products be cleaned and reused?

Yes. They can be maintained easily by methods such as backwashing, ultrasonic cleaning, or manual washing.

4. How can I place an order?

Simply contact us via email or phone, and our team will help assess your requirements and provide a tailored solution.

Contact Details

Email: sam.young@sintered-metal.com

Phone/Whatsapp: +86 158 7769 4221

Get in touch with us today to learn more about our stainless steel mesh filter elements and discover how we can help meet your filtration needs.

VIEW MORETitanium Sintered Filter Elements

VIEW MORETitanium Sintered Filter Elements VIEW MORESintered Porous Metal Tube

VIEW MORESintered Porous Metal Tube VIEW MORESS Sintered Filter

VIEW MORESS Sintered Filter VIEW MORESintered SS Filters

VIEW MORESintered SS Filters VIEW MOREStainless Steel Sintered Mesh Filter Elements

VIEW MOREStainless Steel Sintered Mesh Filter Elements VIEW MOREHigh Quality Stainless Steel Filter Element

VIEW MOREHigh Quality Stainless Steel Filter Element VIEW MOREStainless Steel Filter Element Product

VIEW MOREStainless Steel Filter Element Product VIEW MOREStainless Steel Filter Element Products

VIEW MOREStainless Steel Filter Element Products

_1742364652633.webp)