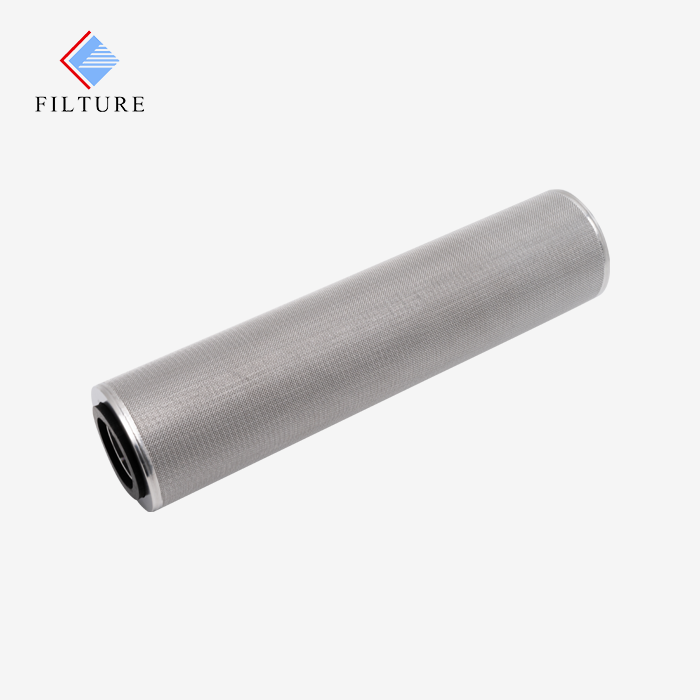

Stainless Steel Sintered Mesh Filter Elements

Absolute Rate

Cleanable

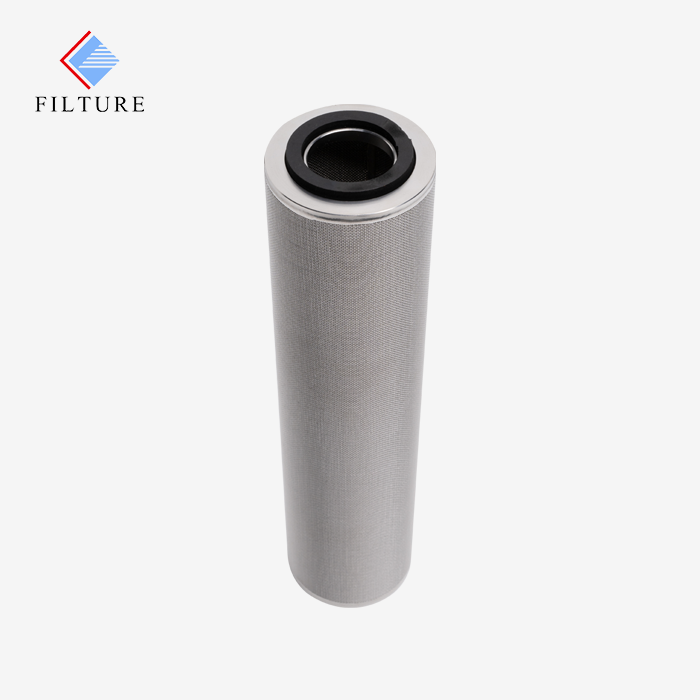

Available Sizes:

Outer Diameter: 60mm(2.36")

Length: 254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: Above 1um

- Product Description

Stainless Steel Sintered Mesh Filter Elements: High-Performance Filtration Solutions

Welcome to Shaanxi Filter New Material Co., Ltd., your trusted partner for stainless steel sintered mesh filter elements. Our sintered metal filters are engineered to provide exceptional filtration performance in some of the harshest industrial environments. Whether you need solutions for high temperature, high pressure, or corrosive conditions, our filters are designed to meet the stringent needs of industries such as petrochemical, aerospace, medical devices, and more.

Product Introduction

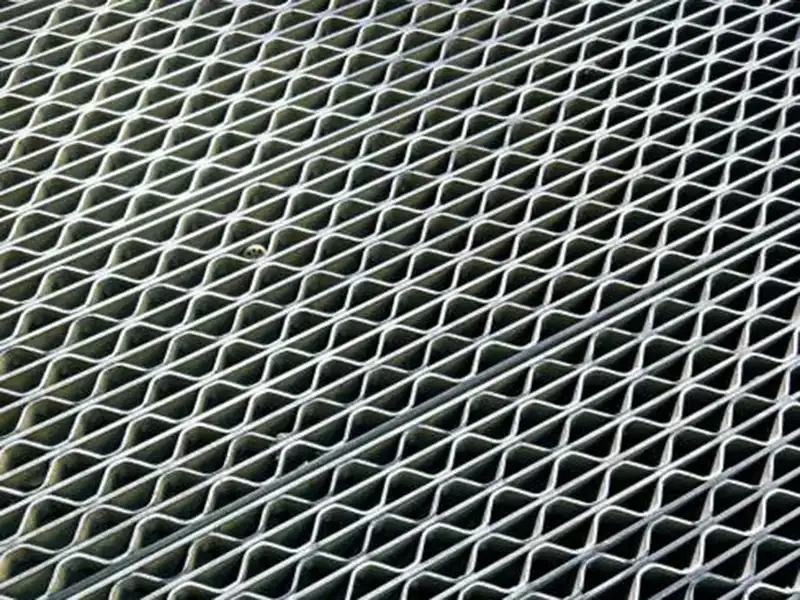

The products are made from multiple layers of stainless steel mesh that are sintered together to create a robust and durable filter. These filters are renowned for their high-temperature resistance, corrosion resistance, and structural stability. They are ideal for industries requiring precise filtration and high-performance materials. Whether you are dealing with extreme conditions like high pressure or high temperatures, our sintered mesh filters deliver consistent, reliable performance.

Technical Specifications

| Specification | Value |

|---|---|

| Material | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 1-200 microns |

| Filtration Efficiency | 99.9% |

| Operating Temperature | Up to 800°C (1472°F) |

| Operating Pressure | Up to 30 MPa (4350 psi) |

| Thickness | 1.0 mm to 10 mm |

| Porosity | High porosity (open flow structure) |

| Shape | Round, Square, Custom Shapes Available |

These technical specifications make our products perfect for industries requiring high-efficiency filtration systems that can withstand extreme working conditions.

|  |  |  |  |

Product Features

- Tall Porosity & Solidness: Our channels are outlined with tall porosity, which permits for successful filtration whereas guaranteeing negligible weight drop. They are fantastically tough, indeed in challenging mechanical environments.

- Corrosion & Temperature Resistance: The stainless steel development guarantees extraordinary resistance to erosion and tall temperatures, making them idealize for utilize in petrochemical, vitality, and aviation industries.

- Reusability & Simple Upkeep: Our sintered work channels can be cleaned and reused numerous times, lessening upkeep costs and giving long-term value.

- Pressure Resistance: These channels can withstand high-pressure situations without losing auxiliary astuteness, making them a dependable arrangement for requesting filtration applications.

Applications

The products are used across various industries for applications such as:

- Petrochemical Industry: For filtration of oils, gases, and other chemicals under high temperatures and pressures.

- Aerospace: Used in high-performance filtration systems where lightweight, durable materials are essential.

- Pharmaceuticals: Ensuring purity by filtering fine particles from gases or liquids.

- Food and Beverage: For high-precision filtration in food production lines and beverage filtration systems.

- Gas Filtration: Effective in separating particles and contaminants from gases in industrial processes.

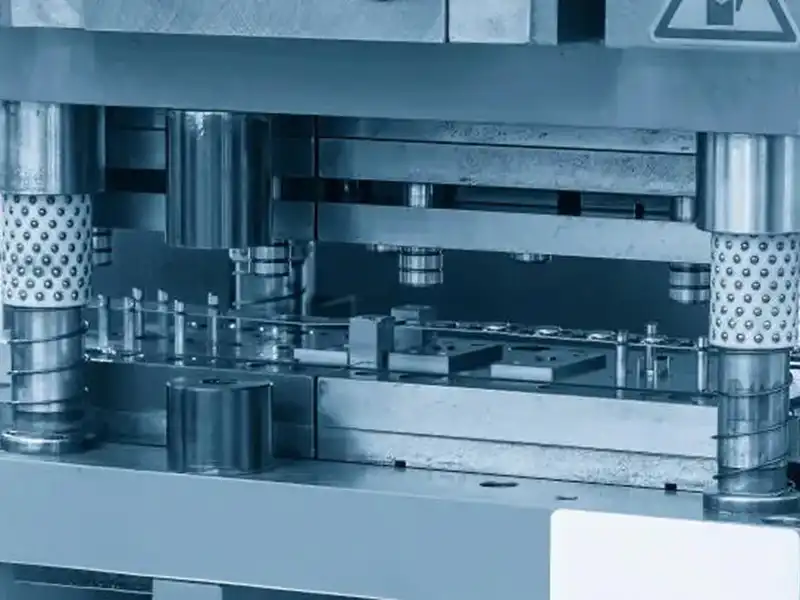

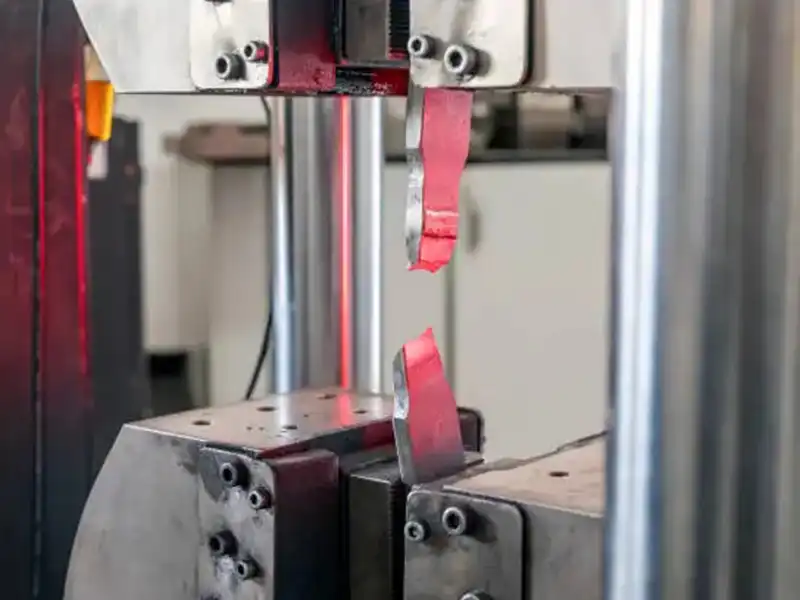

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We recognize that each industrial process comes with unique requirements. That’s why we provide tailored solutions with Stainless Steel Sintered Mesh Filter Elements, designed to match your exact specifications. Whether you require variations in size, aperture, or shape, our flexible production capabilities and expert team ensure the filters meet your precise operational needs.

Quality Assurance

At Shaanxi Filter New Material Co., Ltd., quality is built into every stage of production. Each filter element undergoes strict testing and inspection, guaranteeing compliance with international standards. With certifications such as ISO, CE, and FDA, we ensure that our products deliver consistent reliability and safety in critical applications.

Packaging and Logistics

Our filter elements are carefully packaged using protective materials to prevent any damage during transport. We provide efficient and secure global shipping solutions, ensuring that your order reaches you safely and on time—whether in North America, Asia-Pacific, Europe, or the Middle East.

Customer Support

We pride ourselves on offering exceptional customer service. Our technical team is ready to assist with product selection, system integration, installation, and ongoing maintenance. For any inquiries or assistance, please contact us at sam.young@sintered-metal.com.

Why Choose Us

With years of expertise in filtration technology, we have become a trusted partner for industries worldwide. Our advantages include:

Technical Excellence: Advanced engineering for high-performance results.

Flexible Production: Tailored manufacturing to meet demanding requirements.

Strict Quality Control: Reliable performance under extreme conditions.

Global Service: Timely delivery and comprehensive customer support.

OEM Services

We provide OEM solutions for clients who need specialized designs. From material selection to size and structure, we can customize Stainless Steel Sintered Mesh Filter Elements to meet unique technical and branding requirements.

FAQ

1. What is the maximum operating temperature?

Our filter elements can withstand temperatures up to 800°C (1472°F), making them suitable for high-temperature applications.

2. Can these filters be reused?

Yes, the elements are designed for easy cleaning and repeated use, reducing long-term maintenance costs.

3. Do you offer customization?

Absolutely. We customize filters in terms of size, shape, pore size, and material.

4. What industries benefit from these products?

Stainless Steel Sintered Mesh Filter Elements are widely used in petrochemical, aerospace, pharmaceutical, food and beverage, and energy industries.

Contact Details

For inquiries or technical support, please contact us at:

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +8615877694221

If you’re ready to get in touch and order high-performance stainless steel sintered mesh filter elements, don’t hesitate to contact us. Our team is ready to provide you with the best solutions to meet your filtration needs!

VIEW MORESterile Titanium Filter Element

VIEW MORESterile Titanium Filter Element VIEW MOREStainless Steel Filter Elements

VIEW MOREStainless Steel Filter Elements VIEW MOREStainless Steel Mesh Filter Element

VIEW MOREStainless Steel Mesh Filter Element VIEW MOREHigh Quality Stainless Steel Filter Element

VIEW MOREHigh Quality Stainless Steel Filter Element VIEW MOREStainless Steel Filter Element Product

VIEW MOREStainless Steel Filter Element Product VIEW MOREStainless Steel Filter Element Products

VIEW MOREStainless Steel Filter Element Products VIEW MOREMetal Sintered Porous Disc

VIEW MOREMetal Sintered Porous Disc VIEW MORESintered Metal Felt

VIEW MORESintered Metal Felt

_1742364652633.webp)