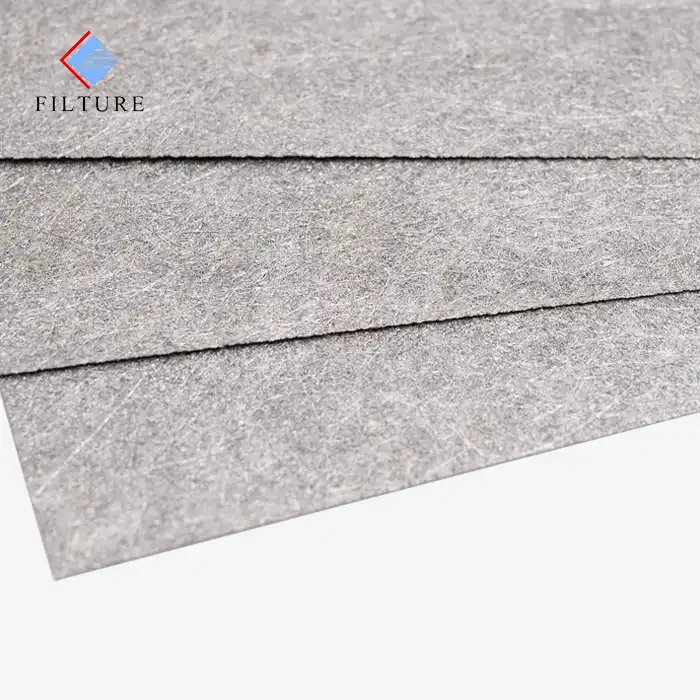

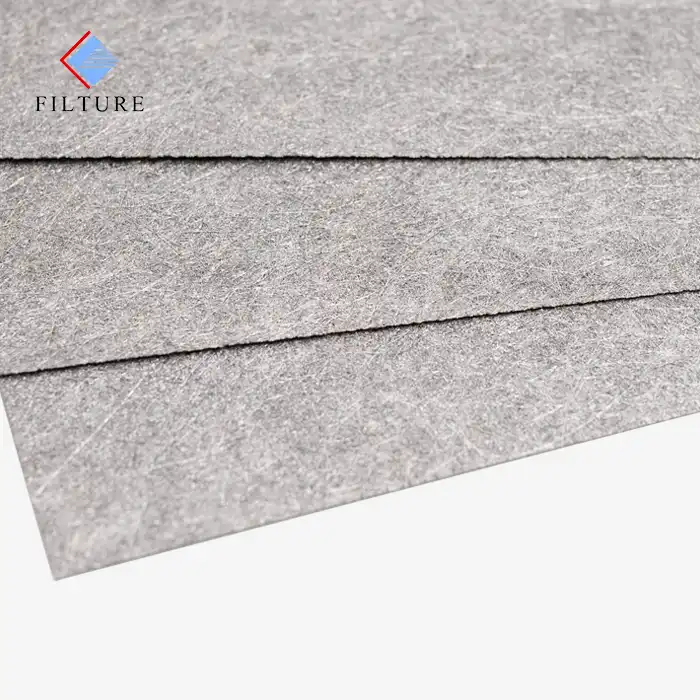

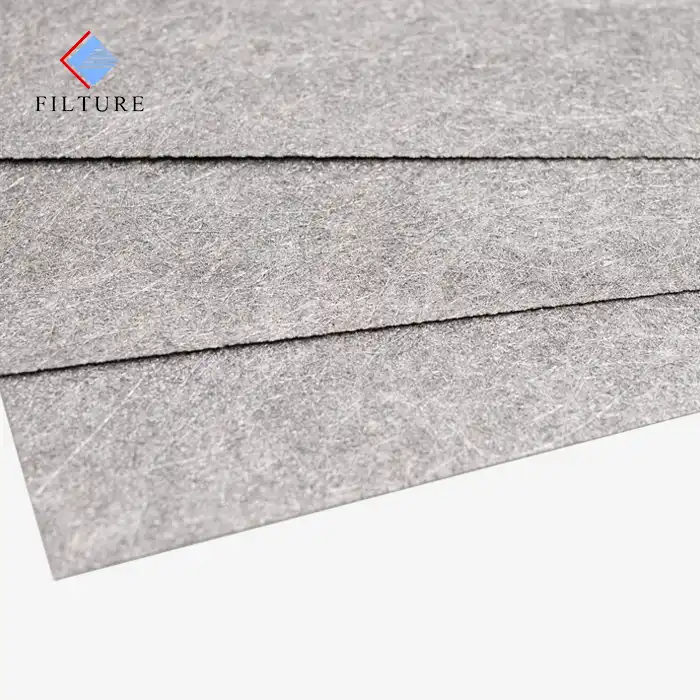

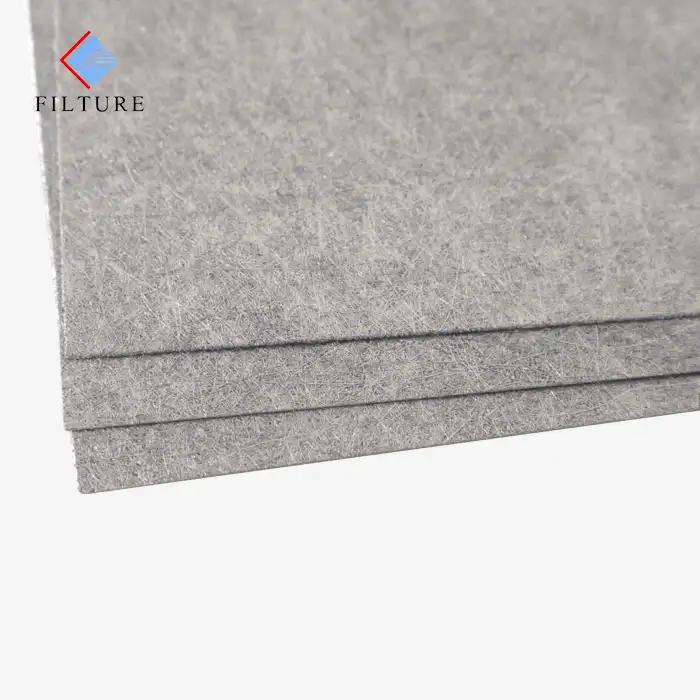

Sintered Metal Fiber

Thickness: 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2 - 5.0mm;

Porosity: optional within 20% - 90%;

Maximum external dimension: 1200 x 1200mm, and specific dimensions can be cut according to customers' requirements.

- Product Description

Sintered Metal Fiber Filters: The Ultimate Solution for High-Performance Filtration

Engineered for demanding industrial applications, our sintered metal fiber filters deliver outstanding filtration performance under extreme conditions. With exceptional resistance to high temperatures, corrosive chemicals, and intense pressures, these filters ensure reliable stability and efficiency across a variety of industries. From energy and chemical processing to aerospace, they provide a durable, high-performance solution for long-term filtration needs.

Technical Specifications

| Property | Details |

|---|---|

| Material | Stainless Steel, Titanium, Nickel, etc. |

| Pore Size Range | 0.1 µm – 100 µm |

| Filtration Efficiency | 99.99% (depending on pore size and material) |

| Operating Temperature | -200°C to +900°C |

| Operating Pressure | Up to 100 bar |

| Permeability | High porosity with precise permeability rates |

|  |  |  |

|  |  |  |

Key Features

- High Porosity: Offers excellent flow capacity while maintaining fine filtration capabilities.

- Durability: Resistant to wear and tear, ensuring long product life with minimal maintenance.

- Easy Cleaning & Reuse: Filters can be cleaned and reused, reducing operational costs and downtime.

- Heat & Corrosion Resistance: Ideal for extreme conditions such as high heat, chemical exposure, and pressure fluctuations.

- Structural Stability: Multi-layer sintered design enhances strength and performance in harsh environments.

Applications

Sintered metal fiber filters are widely used across various industries due to their versatile filtration capabilities:

- Energy Sector: Filtration for oil, gas, and power generation equipment, ensuring smooth operations under high pressures and temperatures.

- Chemical Industry: Effective for gas separation, catalytic reactions, and solvent filtration.

- Aerospace: Used in aircraft and space applications for reliable filtration of fluids and gases under extreme conditions.

- Medical Field: Providing certified filtration solutions for medical devices and life sciences equipment, ensuring patient safety and performance.

Manufacturing Process

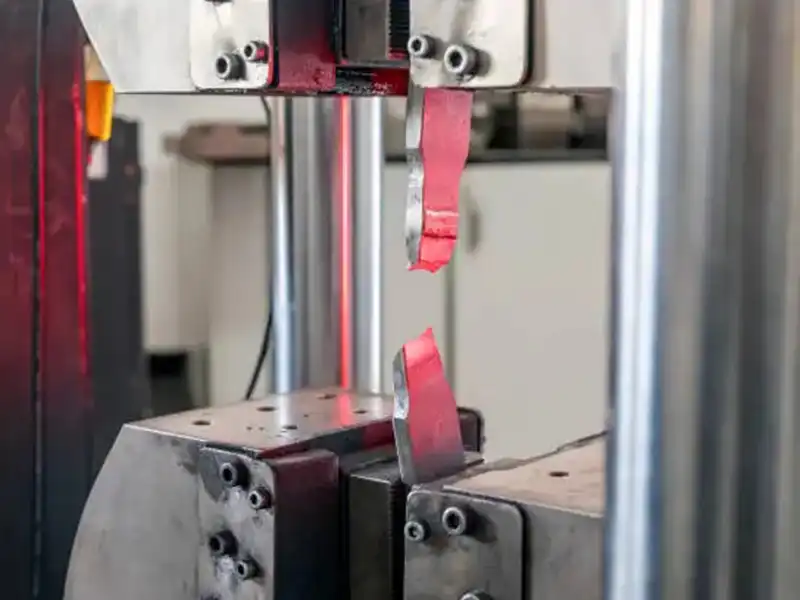

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

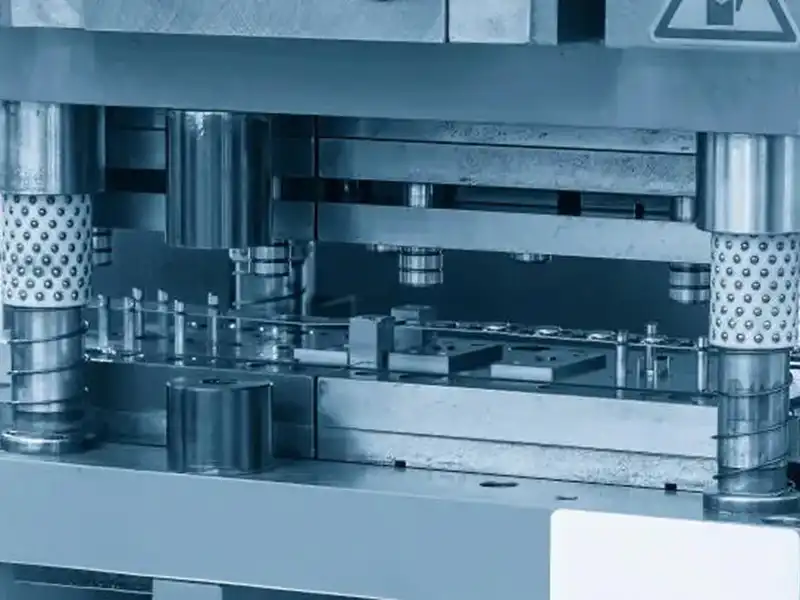

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

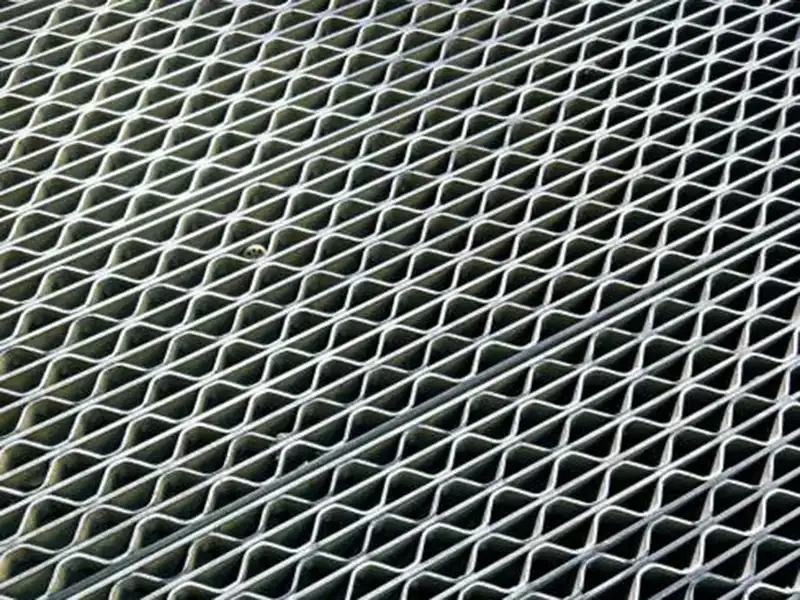

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

Our filters can be tailored to meet your exact requirements, including variations in size, material, shape, and aperture. Whether you need a unique design for a specialized application or a specific material composition, our flexible production capabilities ensure precise customization.

Quality Assurance

These high-performance filters undergo strict quality control to guarantee durability and reliability. We comply with international certifications such as ISO, CE, and FDA, and every product is thoroughly tested before shipment to meet the highest safety and performance standards.

Packaging and Logistics

Each filter is carefully packaged to prevent damage during transit. Our efficient global logistics network ensures timely and secure delivery, keeping your operations on schedule no matter where you are located.

Customer Support

Our dedicated team is available for pre-sales consultations, product selection guidance, and post-sales technical support. From installation advice to maintenance and troubleshooting, we provide expert assistance throughout the product lifecycle.

Contact Us

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +8615877694221

Why Choose Us?

Experience: Years of expertise in high-performance filtration solutions.

Customization: Flexible production to meet your unique specifications.

Quality: Products engineered for reliable long-term performance.

Timely Delivery: Efficient logistics to ensure on-time delivery worldwide.

Customer Support: Comprehensive pre- and post-sales assistance.

OEM Services

We offer OEM solutions to manufacture filters according to your specific needs. From custom dimensions to specialized designs, our production process ensures high-quality, tailor-made results.

FAQ

What is the maximum temperature these filters can withstand?

Depending on the material chosen, they operate reliably between -200°C and +900°C.Can the filters be cleaned and reused?

Yes, they are designed for easy cleaning and multiple reuses, reducing long-term costs.Which industries use these filters?

They are widely applied in energy, chemical, aerospace, and medical sectors, where high-efficiency filtration is required under extreme conditions.

Contact Us

To get a quote or discuss your specific requirements, contact us today:

Email: sam.young@sintered-metal.com

Phone/Whatsapp: +8615877694221

By focusing on high-quality sintered metal fiber filters, we aim to help your business succeed with reliable, customized filtration solutions. Let us be your trusted partner in meeting your filtration needs. Reach out now for more information!

_1742364652633.webp)