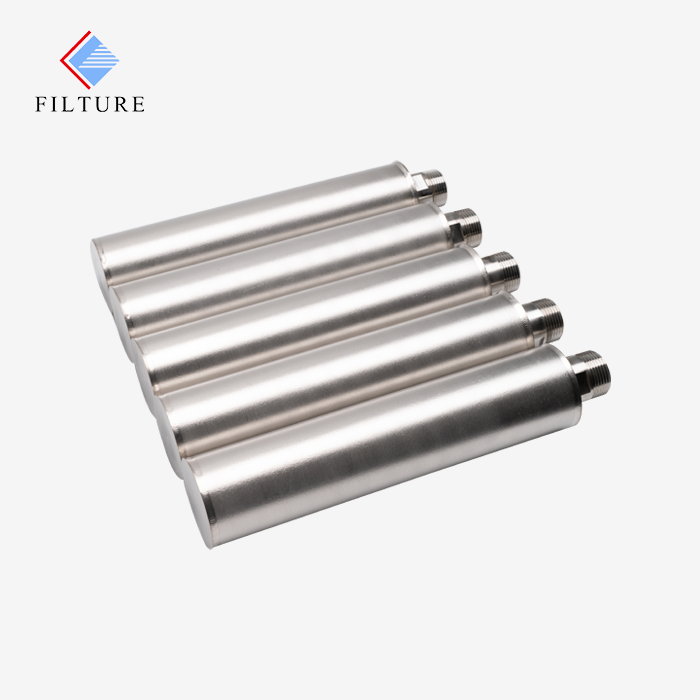

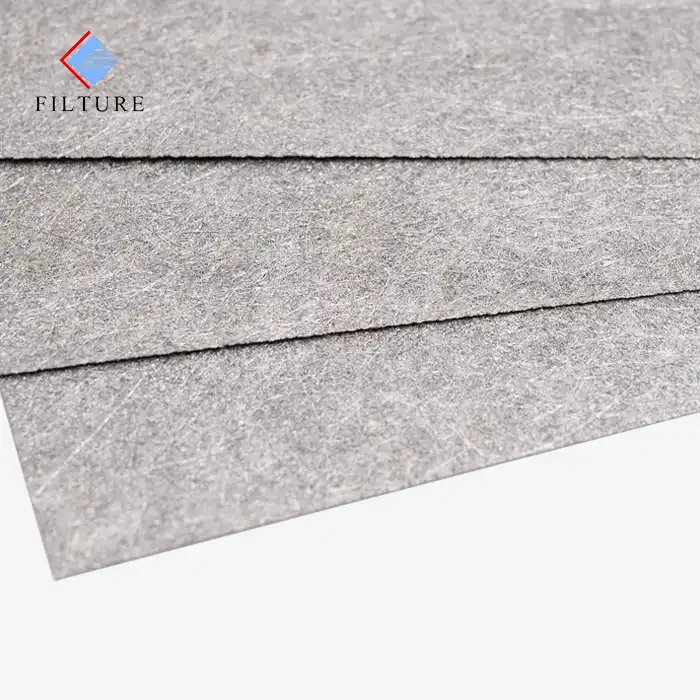

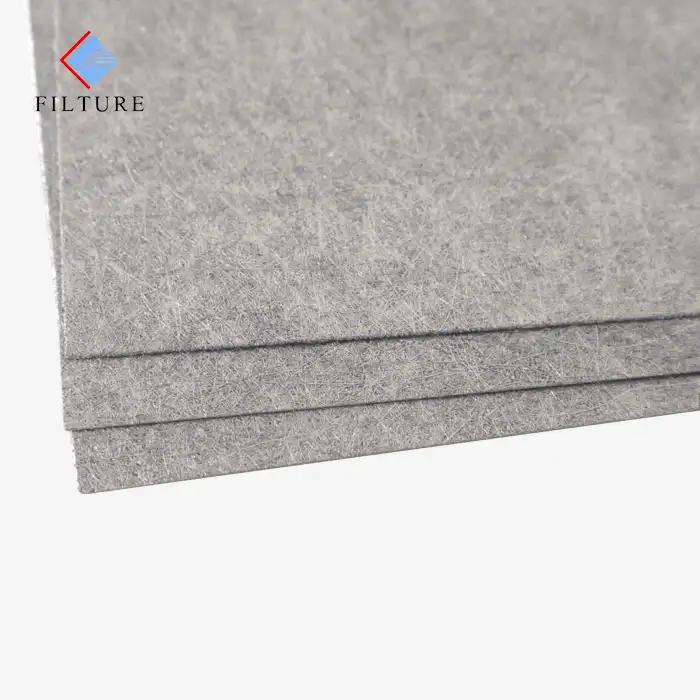

Sintered Metal Felt

Thickness: 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2 - 5.0mm;

Porosity: optional within 20% - 90%;

Maximum external dimension: 1200 x 1200mm, and specific dimensions can be cut according to customers' requirements.

- Product Description

Introduction to Sintered Metal Felt

Sintered metal felt is a high-performance filtration material engineered for the most demanding industrial applications. Crafted from premium metal fibers, it delivers exceptional heat and corrosion resistance along with outstanding structural stability, making it ideal for environments with extreme temperatures, high pressures, and aggressive chemicals. Whether used in energy, chemical, or aerospace industries, this material provides reliable durability and consistent performance to support smooth operations.

Technical Specifications

| Property | Specification |

|---|---|

| Material | Stainless Steel, Titanium, Nickel, etc. |

| Pore Size Range | 10 µm to 500 µm |

| Filtration Efficiency | 95% to 99% (depending on pore size) |

| Operating Temperature | Up to 800°C (depending on material) |

| Operating Pressure | Up to 30 MPa (depending on thickness and material) |

| Thickness | 0.5 mm to 5 mm |

| Porosity | 40% to 80% |

| Weight | Lightweight, varying by material and thickness |

|  |  |  |

|  |  |  |

Key Features

High Porosity: This material features a highly porous structure, enabling efficient filtration while maintaining optimal airflow even in complex systems.

Durability & Reliability: Renowned for long-term stability, it resists wear, corrosion, and deformation, ensuring minimal maintenance and consistent performance.

Easy to Clean & Reuse: Designed for repeated use, it can be cleaned and reused, providing a cost-effective solution for continuous filtration needs.

Temperature & Pressure Resistance: Capable of withstanding extreme temperatures and pressures, it is ideal for demanding applications in energy, chemical, and aerospace sectors.

Corrosion Resistance: Resistant to a wide range of corrosive chemicals and harsh industrial environments.

Applications

This versatile material is widely used across industries requiring high-performance filtration:

Petrochemical Industry: Efficient filtration of oil and gas during extraction and refinement.

Pharmaceutical & Medical: Certified filters for medical devices, life science equipment, and critical applications.

Food & Beverage: Ensures purity and hygiene in liquid and gas filtration processes.

Gas Filtration: Effective in separating contaminants in air and exhaust systems.

Aerospace: Lightweight and durable, suitable for gas separation and filtration in aircraft engines.

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

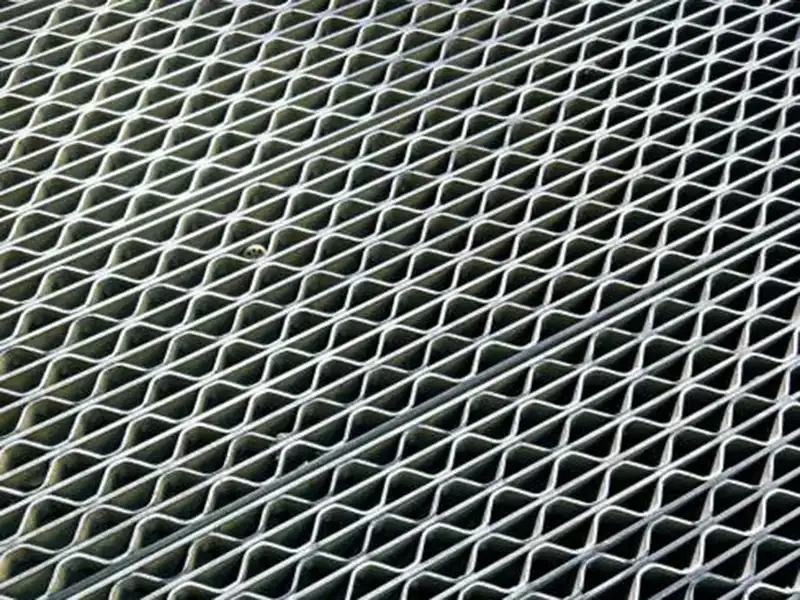

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

At Shaanxi Filture New Material Co., Ltd., we understand that every application has unique requirements. That's why we offer a wide range of customization options for our high-performance filtration materials, including:

Material Selection: Choose from stainless steel, titanium, nickel, or specialized alloys.

Size & Shape: Manufactured to fit any shape or dimension your application requires.

Pore Size: Adjustable to achieve the optimal filtration efficiency for your needs.

Quality Assurance

We are committed to delivering consistent, high-quality filtration solutions. All products undergo stringent testing to meet international standards, including ISO, CE, and FDA certifications. From raw material sourcing to final inspection, every unit is verified to ensure maximum performance and reliability.

Packaging and Logistics

To prevent damage during transit, our filtration materials are carefully packaged using protective materials. Our global logistics network guarantees safe, on-time delivery, with flexible options to suit your project requirements.

Customer Support

Our dedicated team provides expert support before and after your purchase. We assist with product selection, technical guidance, and troubleshooting to ensure optimal use of our filtration products. Contact us at sam.young@sintered-metal.com or Tel/WhatsApp: +8615877694221 for assistance.

Why Choose Us

With extensive experience in the filtration industry, Shaanxi Filture New Material Co., Ltd. is a trusted supplier of sintered metal felt. We provide:

Custom Solutions: Tailored to your specific operational requirements.

High-Quality Products: Manufactured to the highest standards.

Timely Delivery: Ensuring smooth operations without delays.

Exceptional Customer Support: Professional guidance throughout your experience.

OEM Services

We also offer OEM manufacturing services for fully customized filtration solutions. Share your specifications with us, and we will deliver products designed to meet your exact needs.

FAQ

Q: What industries use this filtration material?

A: It is widely used in petrochemical, pharmaceutical, aerospace, and food processing applications.

Q: How is it cleaned?

A: The material can be cleaned with ultrasonic cleaning, backflushing, or other suitable methods depending on the application.

Q: Can it be customized?

A: Yes, we offer tailored options for material, pore size, and dimensions to meet your specific requirements.

For more information or to request a quote, please contact us:

Email: sam.young@sintered-metal.com

Tel/Whatsapp: +8615877694221

_1742364652633.webp)