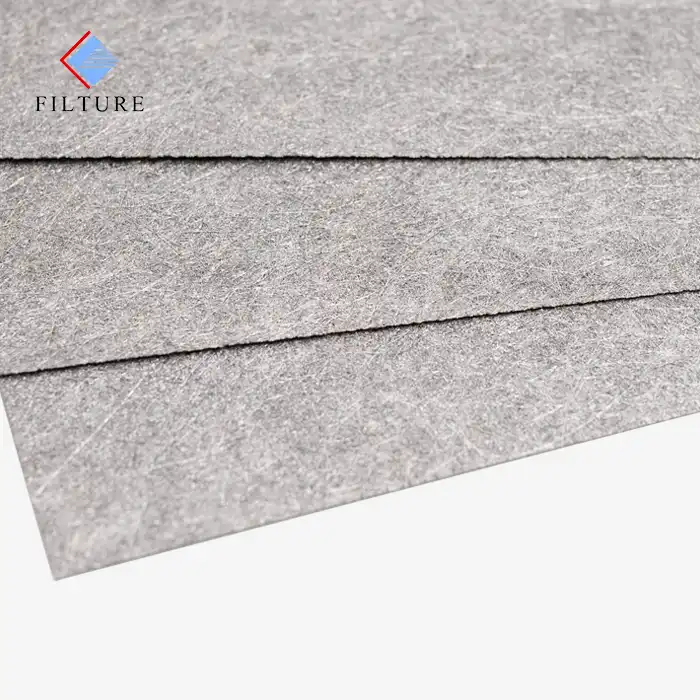

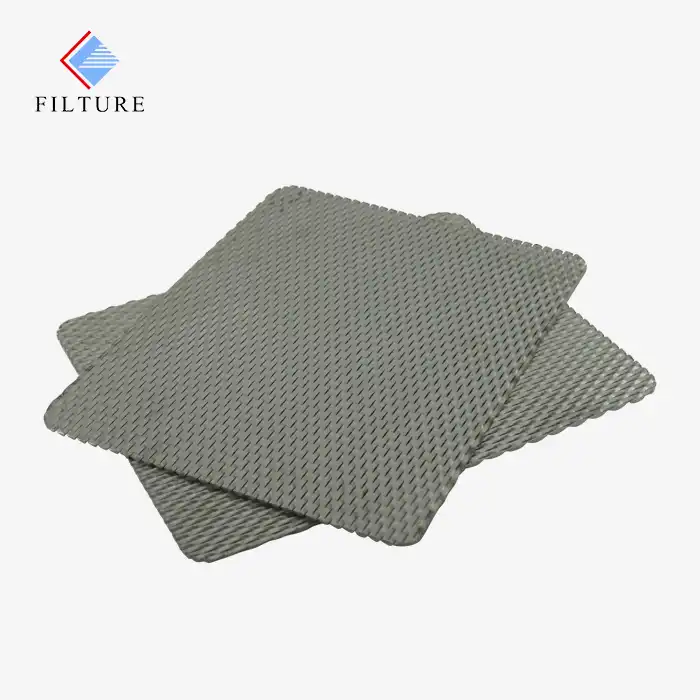

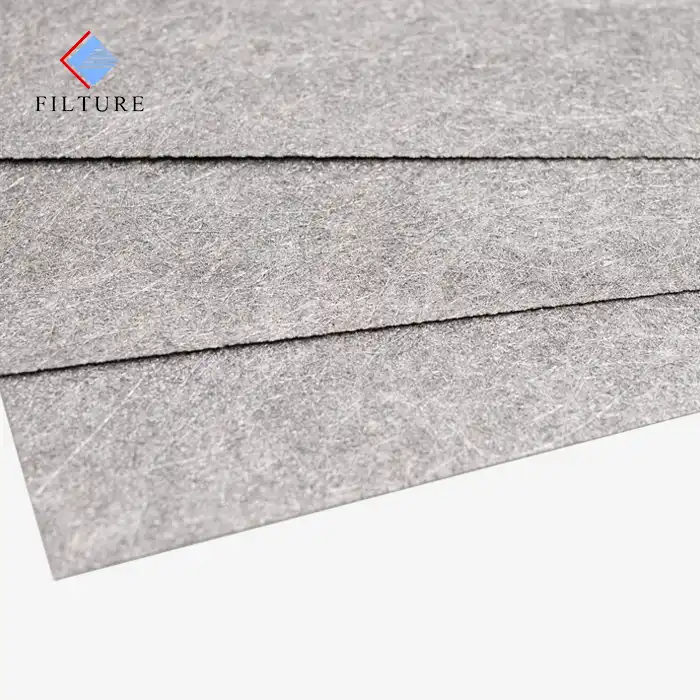

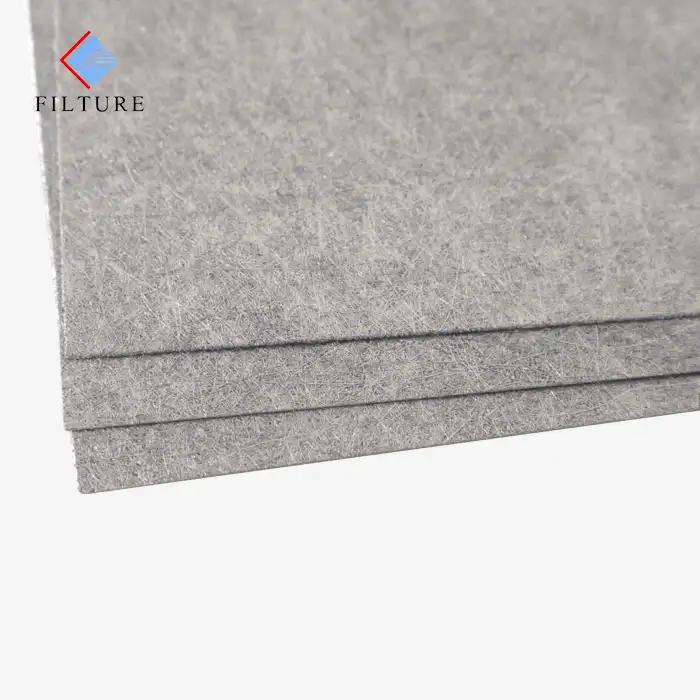

Sintered Filter Felt

Thickness: 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2 - 5.0mm;

Porosity: optional within 20% - 90%;

Maximum external dimension: 1200 x 1200mm, and specific dimensions can be cut according to customers' requirements.

- Product Description

Sintered Filter Felt: High-Performance Filtration Solutions for Extreme Environments

For demanding filtration applications, our sintered filter felt provides a high-performance solution. Engineered to withstand extreme temperatures, pressures, and corrosive conditions, this versatile material ensures exceptional filtration, separation, and purification efficiency. At Shaanxi Filture New Material Co., Ltd., we deliver customized elements tailored to diverse industrial needs, guaranteeing reliability and long-lasting performance across multiple sectors.

Technical Specifications

| Specification | Value |

|---|---|

| Material Options | Stainless Steel, Titanium, Nickel |

| Pore Size Range | 0.5 µm to 100 µm |

| Filtration Efficiency | ≥ 99% |

| Operating Temperature | -200°C to +600°C |

| Operating Pressure | Up to 40 MPa |

| Permeability | Customizable based on application |

| Durability | High resistance to abrasion and corrosion |

| Dimensions | Custom sizes available upon request |

|  |  |  |

|  |  |  |

Key Features of Sintered Filter Felt

High Porosity: Engineered with a unique structure to enable efficient fluid flow while maintaining superior filtration performance.

Durability and Reusability: Built to withstand high temperatures, corrosive substances, and pressure, this material is easy to clean and reuse, offering a cost-effective solution for long-term applications.

Precision Filtration: The finely designed pores ensure accurate filtration, minimizing contaminants and enhancing the overall quality of your products.

Versatility: Ideal for demanding industrial environments, it delivers reliable filtration under extreme conditions, including high temperatures, high pressures, and chemically aggressive settings.

Applications

This high-performance filtration material is widely used across various industries:

Petrochemical Industry: Efficiently filters oils, gases, and other fluids to maintain operational safety and efficiency.

Pharmaceutical Industry: Ensures high-purity filtration for medicines, meeting strict health and safety standards.

Food and Beverage: Used to filter oils, beverages, and other liquids, providing contamination-free products.

Gas Filtration: Suitable for gas separation, catalytic processes, and other industrial gas applications, ensuring purified output.

Aerospace: Provides lightweight, durable filtration solutions that meet stringent aerospace requirements.

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

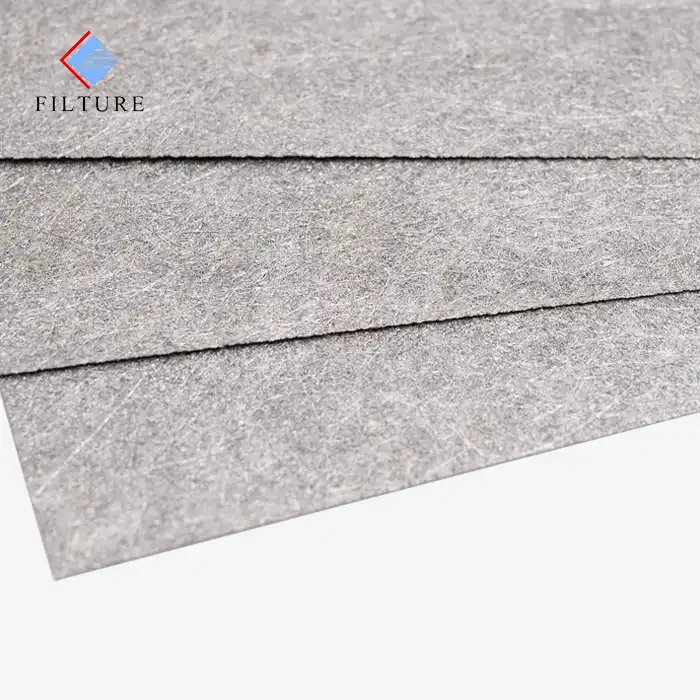

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

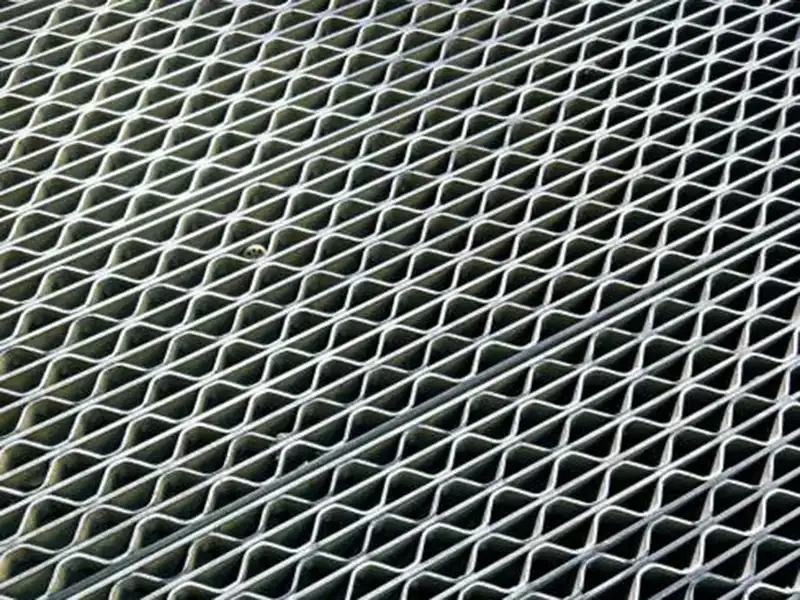

Metal Mesh

Titanium and Stainless Steel metal fibers

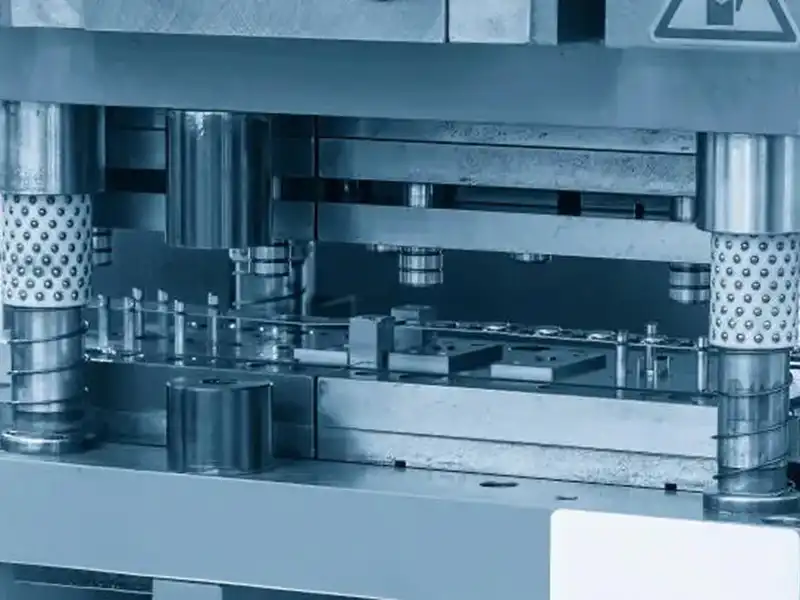

Molding process

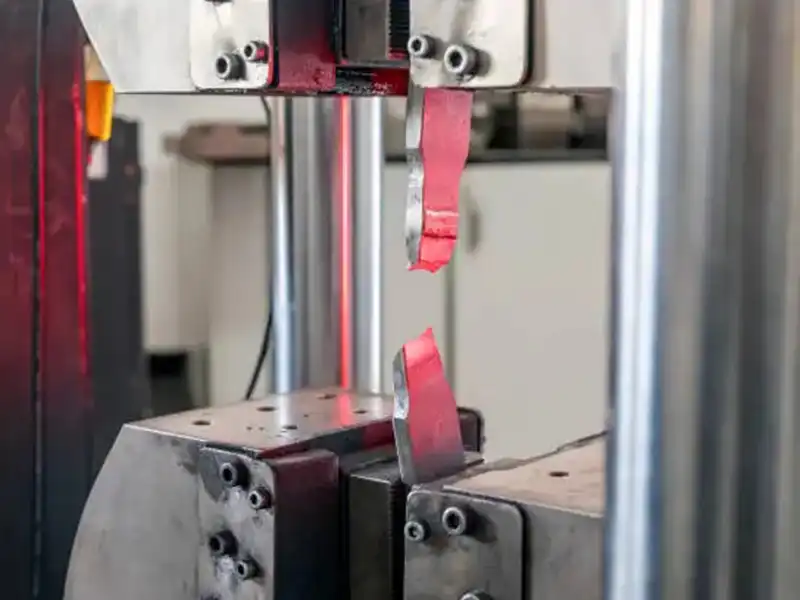

Pressing

High temperature sintering

Welding

Customization Options

We understand that every application has unique requirements. That’s why we offer fully customizable solutions, including:

Materials: Options include stainless steel, titanium, nickel, and other specialty alloys.

Size and Shape: Filter elements can be tailored to your specific dimensional needs.

Pore Size and Permeability: Adjusted to achieve optimal filtration efficiency.

Surface Treatment: Available for enhanced corrosion resistance or other specialized properties.

Our flexible production capabilities ensure we can provide the right solution for your filtration challenges.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., quality is central to our operations. Every product undergoes rigorous testing and inspection to meet international standards, including ISO, CE, and FDA certifications, ensuring consistent performance and reliability.

Packaging and Logistics

We carefully package all products to prevent damage during transit. With reliable logistics partners, we offer flexible delivery options, guaranteeing your orders arrive safely, on time, and in perfect condition.

Customer Support

Our expert support team assists you at every stage, from pre-sales consultation to after-sales service. We provide technical guidance, installation support, and troubleshooting to ensure your filtration products operate at peak efficiency.

Why Choose Us?

With years of experience and advanced production capabilities, Shaanxi Filture New Material Co., Ltd. is a trusted partner for high-quality filtration solutions. We focus on customized products, rigorous quality standards, and responsive customer service to deliver solutions that exceed expectations.

OEM Services

We provide OEM services, offering fully customized manufacturing solutions. From selecting materials to adjusting dimensions, we ensure each product meets your precise operational requirements.

FAQ

Q: Which industries can benefit from these filtration solutions?

A: Sectors like petrochemical, pharmaceutical, aerospace, food & beverage, and energy industries rely on high-performance filtration for operational efficiency and safety.

Q: How durable are these products?

A: Designed for demanding environments, they are reusable and have a long service life with proper maintenance, making them highly cost-effective.

Q: Can you create custom sizes and specifications?

A: Yes, we offer tailored options for size, pore configuration, and materials to perfectly match your filtration requirements.

Contact Us

If you’re ready to elevate your filtration processes with high-performance sintered filter felt, contact us today!

Email: sam.young@sintered-metal.com

Phone/WhatsApp: +8615877694221

Let us help you find the perfect filtration solution tailored to your needs.

_1742364652633.webp)