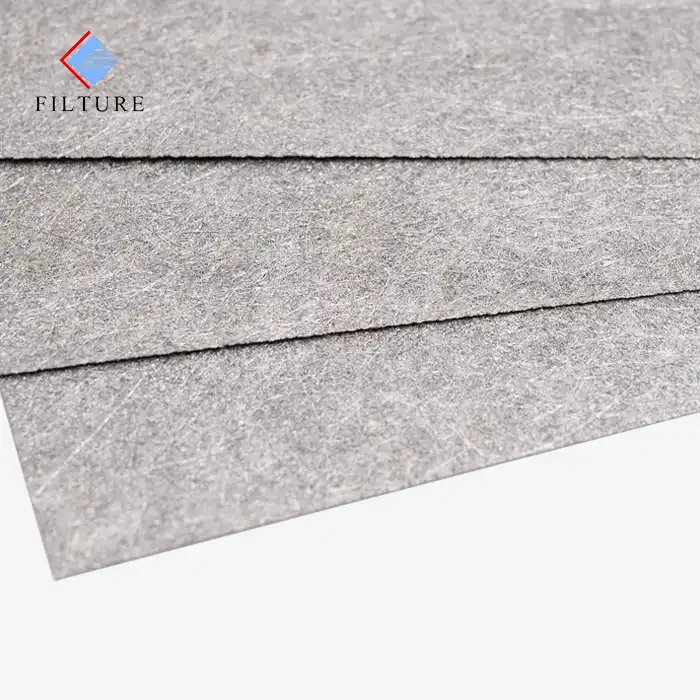

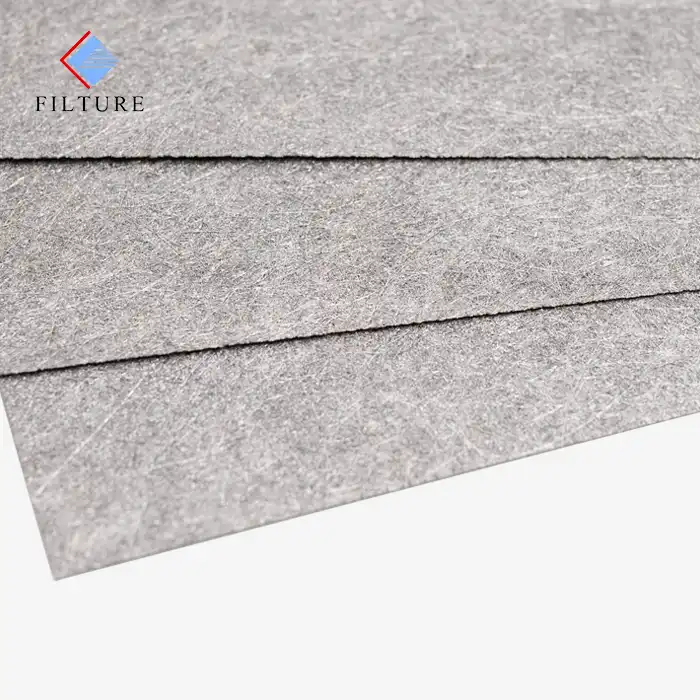

Sintered Metal Fiber Felt

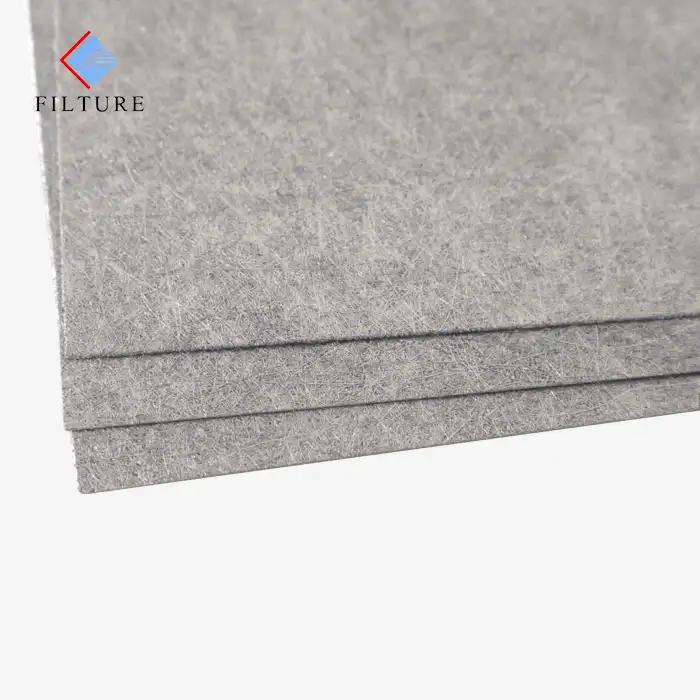

Thickness: 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2 - 5.0mm;

Porosity: optional within 20% - 90%;

Maximum external dimension: 1200 x 1200mm, and specific dimensions can be cut according to customers' requirements.

- Product Description

Sintered Metal Fiber Felt: The Ultimate Solution for High-Performance Filtration

Are you in search of a filtration solution that is efficient, durable, and fully customizable? Our advanced sintered metal fiber felt is engineered for the most demanding industrial environments, offering excellent high-temperature resistance, superior corrosion protection, and exceptional structural stability. It is the perfect choice for sectors such as aerospace, energy, chemical processing, pharmaceuticals, and other industries where consistent performance and reliability are critical.

Technical Specifications

| Specification | Value |

|---|---|

| Materials | Stainless steel, Titanium, Nickel, Alloy Steel |

| Pore Size | 1 - 200 microns |

| Filtration Efficiency | 99.9% (depending on pore size) |

| Operating Temperature | Up to 1000°C (1832°F) |

| Operating Pressure | 10 - 100 bar (depending on material) |

| Thickness | 1 - 10 mm |

| Shape & Size | Customizable (round, square, discs, and more) |

|  |  |  |

|  |  |  |

Product Features

High Porosity: Its unique structure provides excellent porosity, ensuring optimal airflow while delivering superior filtration performance.

Durability & Reusability: Built to withstand harsh environments, this material is highly durable and can be easily cleaned and reused, reducing long-term maintenance costs.

Temperature & Corrosion Resistance: Capable of enduring extreme temperatures and corrosive substances, it is suitable for demanding industries such as chemical processing, aerospace, and power generation.

Pressure Resistance: Strong enough to handle high pressures, making it ideal for filtration in challenging applications.

Applications

This advanced filtration material serves a variety of industries requiring high-performance solutions:

Petrochemical Industry: Provides efficient filtration for oil and gas refining, removing contaminants and ensuring smooth operations.

Pharmaceutical & Food Processing: Used for liquid and gas filtration to ensure purity and compliance with stringent industry standards.

Gas Filtration: Suitable for air purification, gas separation, and removing harmful particles in critical processes.

Energy & Power Generation: Protects machinery and systems from particulates, maintaining efficiency in power plants and other energy facilities.

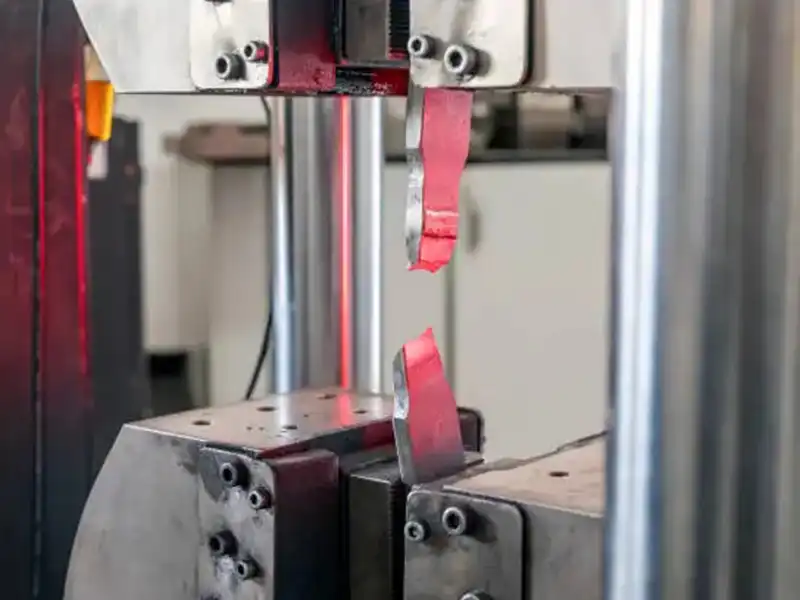

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

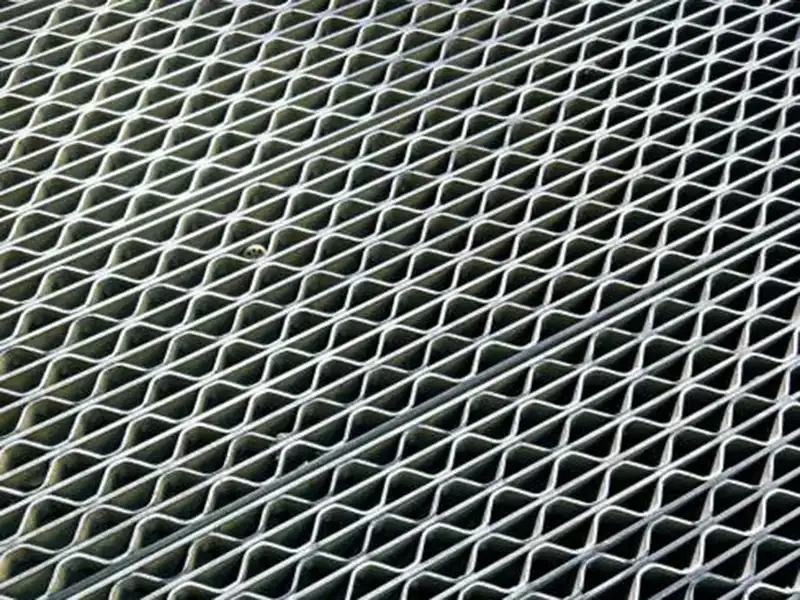

Metal Mesh

Titanium and Stainless Steel metal fibers

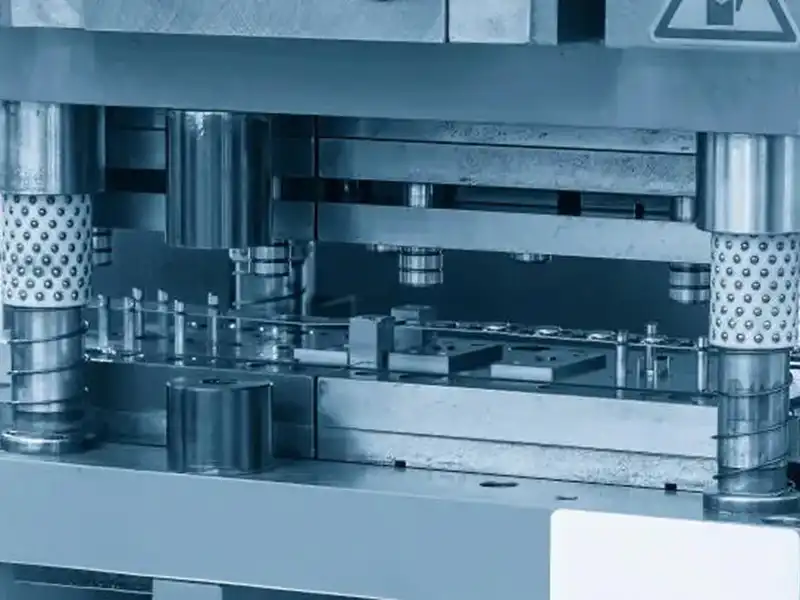

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We understand that every customer has unique requirements. That’s why we offer tailored solutions using advanced sintered metal fiber felt. Whether you need specific shapes, sizes, materials, or pore structures, we can customize our products to meet your exact operational needs. This flexibility is a key reason we are recognized as an industry leader.

Quality Assurance

At Shaanxi Filture New Material Co., Ltd., we are committed to delivering products of the highest quality. All our filters undergo rigorous quality control processes and comprehensive testing to ensure reliability and consistent performance. Our products meet international standards such as ISO and CE, providing confidence in durability and compliance with industry norms.

Packaging and Logistics

We take great care in packaging our products to ensure they arrive safely and in perfect condition. Our efficient logistics system guarantees timely delivery worldwide. From our factory to your facility, we ensure secure and prompt transportation.

Customer Support

Our dedication to excellent service extends beyond product delivery. We provide comprehensive technical support throughout the purchasing process and beyond, helping you maximize performance. Have questions? Our expert support team is available for troubleshooting, installation guidance, and product inquiries.

Why Choose Us

Partnering with Shaanxi Filture New Material Co., Ltd. means working with a company with years of experience in the filtration industry. Our advanced production capabilities, customized services, and exceptional product quality have earned us a global reputation. Our focus on quality assurance, timely delivery, and responsive customer support makes us the preferred choice for industrial filtration solutions.

OEM Services

We offer OEM services for clients requiring custom filtration solutions. Whether you need a unique design, specific material, or tailored dimensions, we provide flexible solutions to meet your exact requirements.

FAQ

What is sintered metal fiber felt made from?

It is produced from metal fibers such as stainless steel, titanium, or nickel, which are sintered together to create a durable and highly porous material.Which industries benefit from this filtration material?

It is ideal for sectors like petrochemical, pharmaceuticals, aerospace, and energy, where high-performance filtration is essential.What is the maximum operating temperature?

Our filters can withstand temperatures up to 1000°C (1832°F), making them suitable for the most extreme environments.

Contact Us

Ready to take your filtration solutions to the next level? Contact us today at:

- Email: sam.young@sintered-metal.com

- Phone/Whatsapp: +8615877694221

Let us help you find the perfect sintered metal fiber felt solution for your needs.

_1742364652633.webp)